Importance of Molds in Die Casting

Molds, or dies, are critical to the die casting process. Designed to withstand extreme conditions, these molds are crafted from high-grade steel. They consist of two halves that allow for complex geometries and easy removal of the finished part. Casting die casting molds are often equipped with intricate features such as cores and slides to […]

Our Commitment to Sustainable Manufacturing

In an era where industrial progress and environmental responsibility must go hand in hand, forward-thinking companies are redefining what it means to be a world-class manufacturer. At Juize Machinery, our commitment extends beyond precision and reliability to encompass a genuine dedication to sustainable manufacturing practices. As a Gold Verified Supplier on Alibaba, we believe that true partnership […]

The Die Casting Process

Die casting is a dynamic casting process where molten metal is injected under high pressure into a precision-engineered mold, known commonly as a die. This process starts with the preparation of the metal, usually aluminum or zinc alloys, which are melted in a furnace until they reach a liquid state. Once the metal is […]

How Smart Manufacturing Enhances Precision & Traceability

In the age of Industry 4.0, the most advanced manufacturing is defined not only by machinery but by data intelligence. The true mark of a modern supplier lies in the ability to connect every stage of production into a seamless, transparent, and optimized digital flow. At Juize Machinery, we are integrating smart manufacturing principles into our […]

Engineered for Industry: Tailored Solutions for Demanding Applications

In specialized industries where precision, durability, and performance are non-negotiable, components are not just parts—they are critical system enablers. A failure in a gear, valve, or heat sink can lead to costly downtime, safety risks, or project delays. At Juize Machinery, we understand that different sectors face unique challenges. This is why we go beyond […]

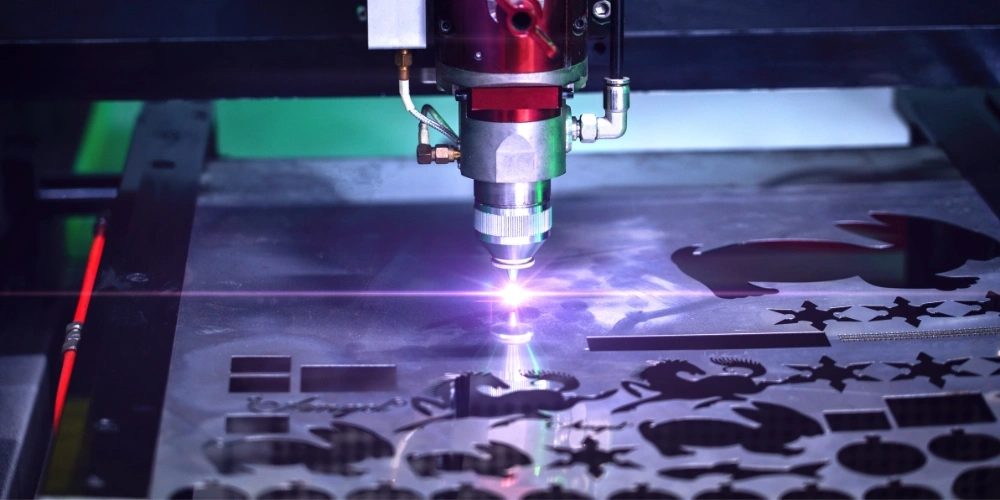

Die casting

Die casting is a precision metal casting process that involves forcing molten metal under high pressure into a mold cavity. This method is distinguished by its speed and the superior quality of the finished products. The origins of die casting trace back to the mid-19th century, initially used for printing type but swiftly adapted […]

CNC Vs Forging

Forging is mainly divided into open-die forging and closed-die forging. Open die forging does not require the use of molds, has low precision, requires subsequent finishing, and is suitable for small batch production of large parts. Closed die forging requires the use of molds, which can produce parts with high precision and complex shapes. […]

Beyond the Part: Adding Value Through Precision Assembly & Integration

In today’s complex product ecosystems, the value delivered by a manufacturing partner is increasingly measured not just by the quality of individual components, but by the completeness and readiness of the final assembly. Managing multiple suppliers for parts and then coordinating a separate assembly process introduces cost, complexity, and risk. At Juize Machinery, we solve […]

Titanium alloys used in CNC Machining

Titanium alloy has a low density of 4.5g/cm³, about 60% of steel. Its strength is higher than aluminum alloy and steel, tensile strength can reach more than 1000MPa, is 2-5 times that of aluminum alloy. Corrosion and temperature resistance are superior to stainless steel and second only to platinum. Moreover, pure titanium is very biocompatible. […]

Engineering Tomorrow: How Integrated Manufacturing Partnerships Drive Innovation

In a landscape defined by rapid technological evolution and shifting market demands, the ability to innovate and adapt has become the ultimate competitive advantage. More than ever, manufacturers are challenged to deliver lighter, stronger, and smarter components at an accelerated pace. At Juize Machinery, we believe the next frontier of innovation isn’t just in the […]