Essential Elements of a Custom Metal Part Production Drawing

A production drawing (also known as a mechanical engineering drawing or blueprint) is the universal language between designers and manufacturers. For custom metal parts, clarity, completeness, and precision are paramount to avoid costly errors and delays. Here are the critical elements it must contain: 1. Title Block This is located in the bottom right corner of […]

Heat Treatment Equipment and Technology

Most factories use special equipment and tools to control the heat treatment processes. Furnaces There are different kinds of furnaces used in the heat treatment process. Batch furnaces are used to treat one load at a time, and it is best used for small parts. Continuous furnaces keep the moving parts through a long […]

Materials Suitable for Forging

Forging is a manufacturing process where metal is shaped using localized compressive forces, typically from a hammer or die. This process aligns the metal’s grain flow, enhancing its strength, toughness, and structural integrity. A wide range of materials can be forged, each chosen for specific mechanical properties and application requirements. The materials are broadly categorized […]

Benefits of Heat Treatment

There are many advantages you get when heat treating metals, such as: The process improves the mechanical properties of metals, making them last much longer under stress. It also makes it easier to work with metals by making them softer through processes such as annealing. Hard metals also hold edges for a longer […]

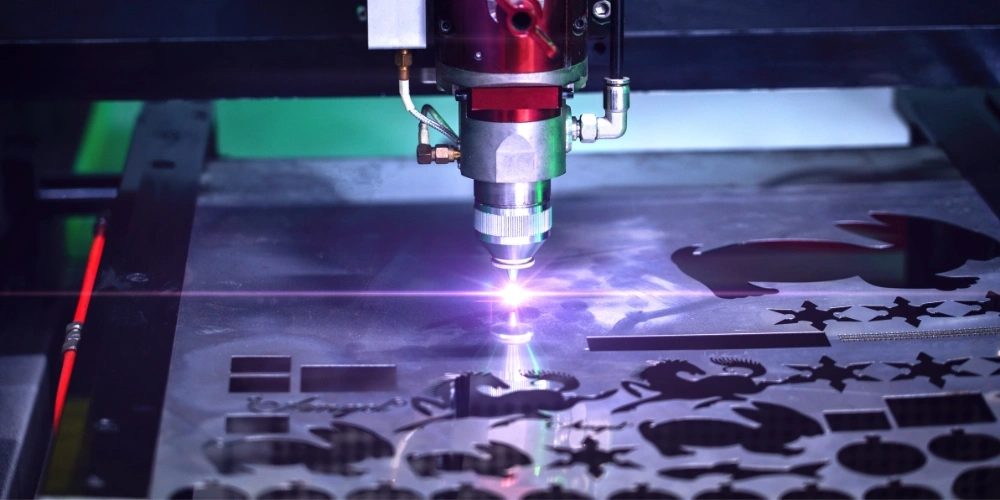

Welding Technology

Welding is a fundamental fabrication process that joins materials, typically metals or thermoplastics, by causing coalescence. This is most often done by melting the workpieces and adding a filler material to form a pool of molten material that cools to become a strong joint. It is distinct from lower-temperature techniques like brazing and soldering, which […]

Does Rust Preventative Oil Affect Welding?

Yes, absolutely. Rust preventative oils have a significantly negative and often dangerous impact on the welding process and the quality of the finished weld. Using oil-coated parts for welding is considered very poor practice and is strictly avoided by professional welders. Here’s a detailed breakdown of why and how it affects welding: 1. Formation of Weld […]

Heat Treatment Equipment and Technology

Most factories use special equipment and tools to control the heat treatment processes. Furnaces There are different kinds of furnaces used in the heat treatment process. Batch furnaces are used to treat one load at a time, and it is best used for small parts. Continuous furnaces keep the moving parts through a long […]

Cooling Methods for Forged Parts

The cooling process immediately following the forging operation is a critical but often overlooked stage in metalworking. It is not merely about bringing the part down to room temperature; it is a continuation of the heat treatment process known as controlled cooling or post-forging heat treatment. The chosen cooling method directly influences the final microstructure, mechanical properties (like […]

Heat Treatment of Different Metals

Steel This is the most commonly used metal when it comes to heat treatment. The carbon content in it can be adjusted to change how hard or tough it becomes. Different heating and cooling methods can be used to change its structure. Aluminum Alloys When applying heat treatment to aluminum, the process can be […]

A Comprehensive Guide to Selecting Dimensional Inspection Tools

Selecting the right dimensional inspection tool, or gage, is a critical decision in manufacturing and quality control. The wrong choice can lead to inaccurate measurements, wasted resources, non-conforming products, and ultimately, a loss of customer trust. The selection process is a systematic evaluation of the part, the measurement requirement, the production environment, and economic factors. […]