Benefits Of CNC Turning

Types Of CNC Lathes There are many types of lathes, but the most common are 2-axis CNC lathes and Swiss-type lathes. Swiss-type lathes are unique in that

Types Of CNC Lathes There are many types of lathes, but the most common are 2-axis CNC lathes and Swiss-type lathes. Swiss-type lathes are unique in that

This type of steel mainly ensures mechanical properties. Therefore, its grade reflects its mechanical properties and is represented by Q+ numbers, where “Q” is the

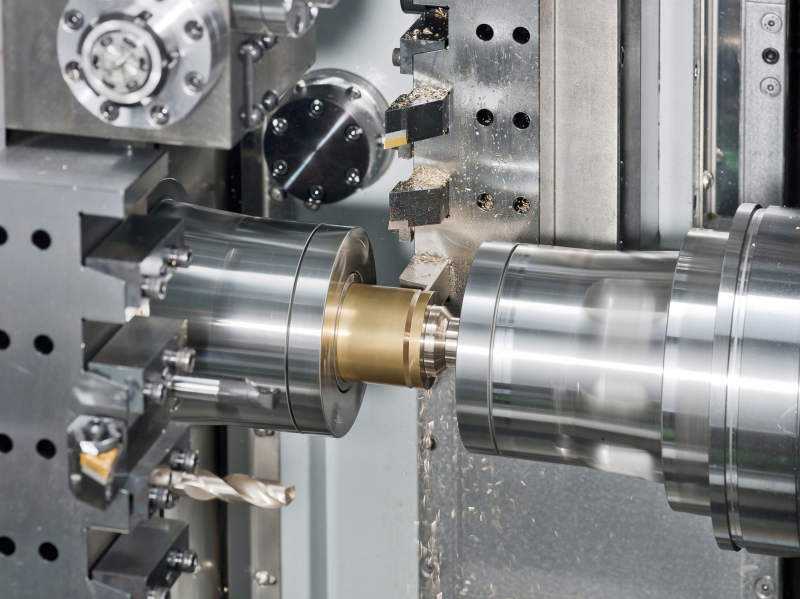

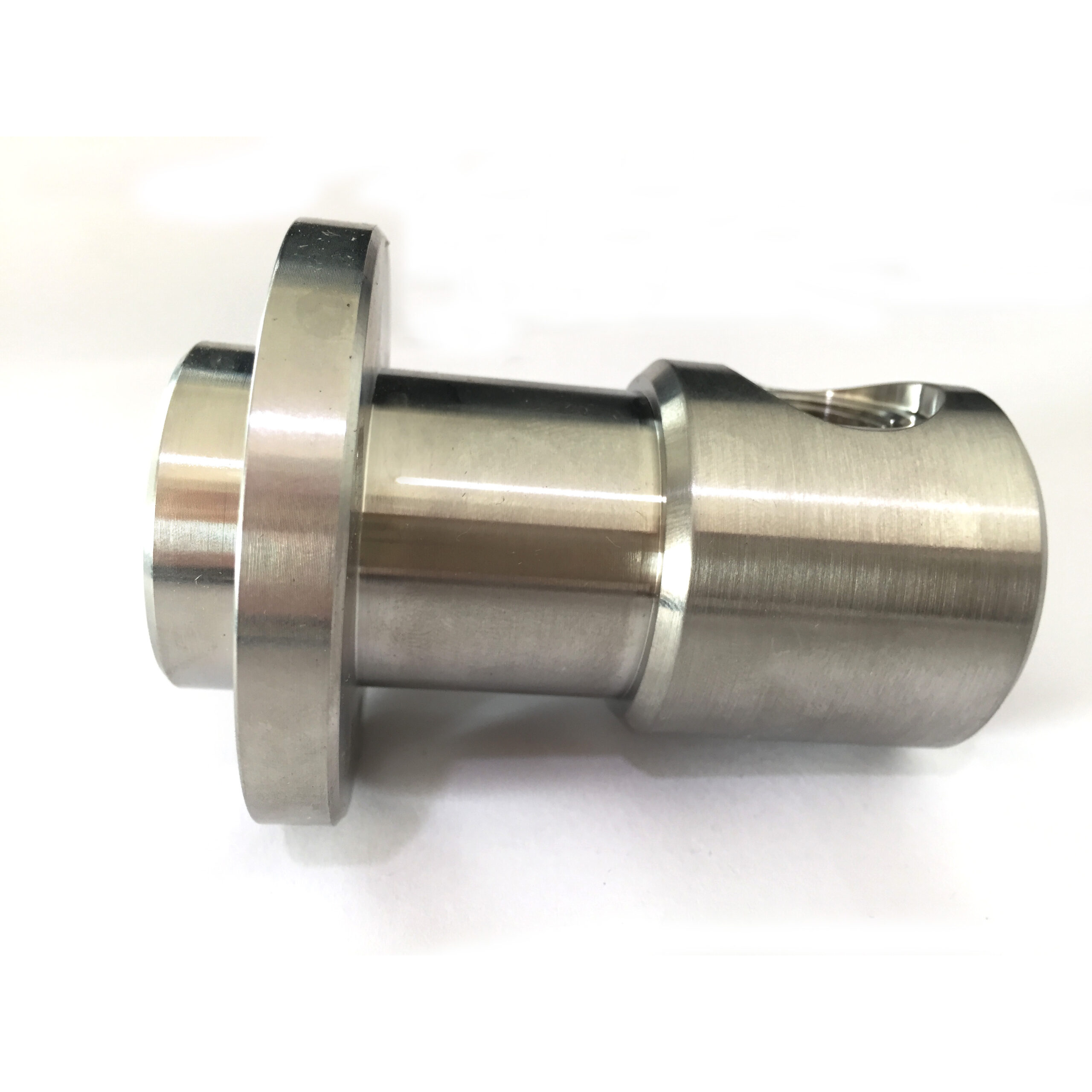

The Basics Of CNC Lathes A CNC lathe machine, also called live tooling lathes, is ideal for cutting any symmetrical cylindrical or spherical parts. Characteristically,

Carbon steel is an iron-carbon alloy with a carbon content of less than 2%. In addition to carbon, carbon steel generally contains small amounts of

In mechanical machining, tolerances refer to the allowable deviation from a specified dimension in a part or component. These tolerances are essential for ensuring the

The pouring speed of steel castings shall be determined according to the specific conditions of castings. For thin-walled castings and castings with complex structures, rapid

The pouring temperature has a great influence on the quality of steel castings. When the pouring temperature is too high, the shrinkage of the molten

1. Cost-Effectiveness Precision grinding is a cost-effective process because of its ability to achieve precise dimensions in large volumes of parts. Not only is the

Precision grinding is a finishing process used in manufacturing to remove small amounts of material from a workpiece. An abrasive grinding tool, usually a rotating

During pouring, the environment around the mold to be cast must be checked. Before pouring, the steel grades of castings shall be aligned, the sandboxes

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.