Benefits of Powder Coating

Some benefits of powder coating include: Improved Durability & Lifespan Enhanced Aesthetics Environmental Friendliness Cost-Effectiveness Improved Durability & Lifespan Powder coating provides a protective layer

Some benefits of powder coating include: Improved Durability & Lifespan Enhanced Aesthetics Environmental Friendliness Cost-Effectiveness Improved Durability & Lifespan Powder coating provides a protective layer

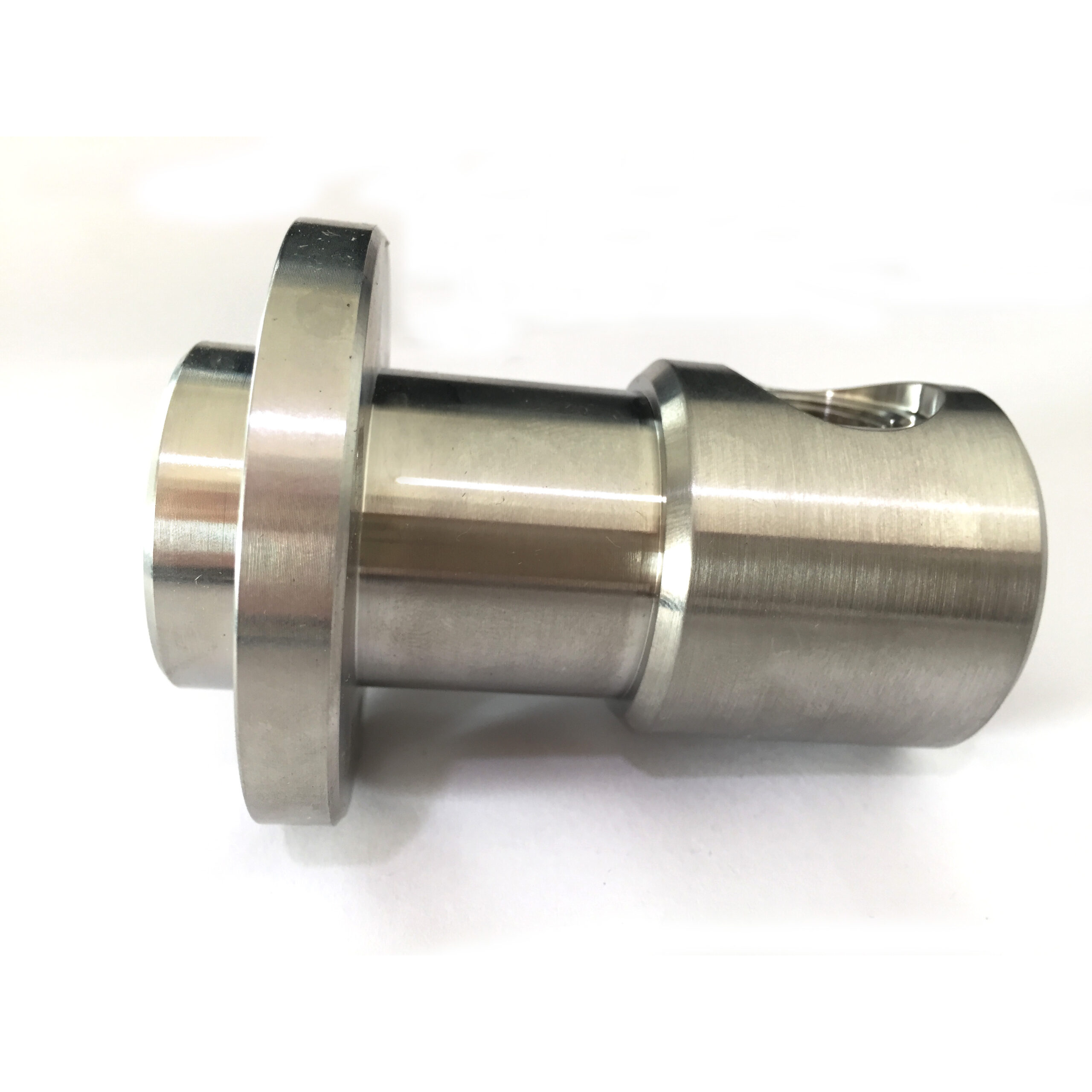

You can broadly categorize a CNC milling machine into eight main components. Further detailed subdivisions are quite complex, and we won’t delve into them here.

Here are some suitable materials that are commonly powder coated. Note that we will work closely with you to achieve the right combination of material and

Here’s how CNC milling differs from CNC turning and CNC grinding: CNC Milling: Involves a cutting tool moving to shape a stationary workpiece. Used for

Powder coat application, as opposed to traditional liquid coating, is achieved through a multi-step process. The steps of the powder coating process typically include: Powder

Powder coating is the process of applying protective coatings to surfaces by applying dry, electrostastically charged powders of typically thermoset or thermoplastic polymer onto a

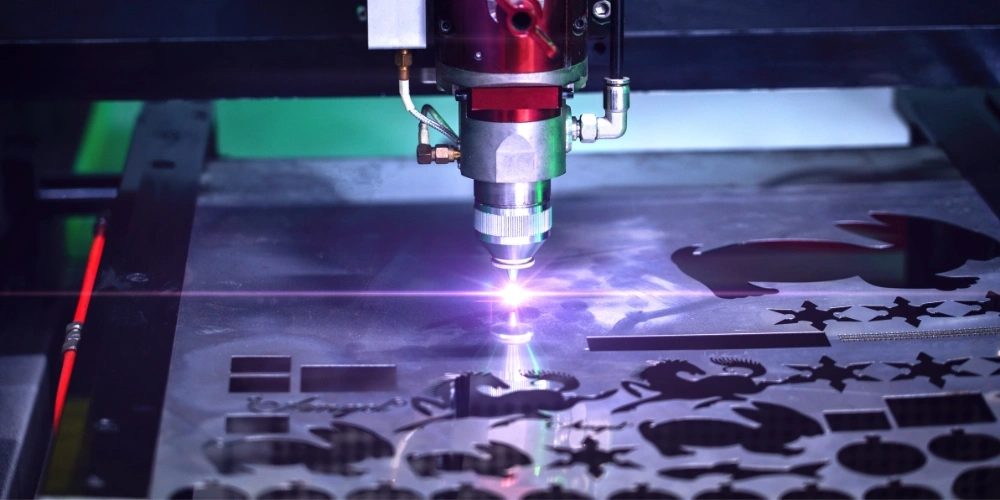

There are multiple types of CNC machines that are used for small batch manufacturing and production. We take advantage of our conspired knowledge, skill, and

CNC machinery and equipment are perfect for batch production – and it’s simply because of one (1) word – repeatability. Repeatability or the idea of

Fractures can occur in essentially three modes, characterized by a specific type of deformation and failure. These modes may result from tensile, compressive, shear, impact,

Fracture in materials describes the process of a material breakage under stress. When a fracture occurs, characteristic behaviors can be observed and analyzed. Listed below

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.