Hot Chamber Die Casting

The hot chamber machine’s injection mechanism is immersed in molten metal. The molten metal fills the cylinder when the piston rises, and the port opens.

The hot chamber machine’s injection mechanism is immersed in molten metal. The molten metal fills the cylinder when the piston rises, and the port opens.

In the cold chamber die casting process, the corrosion problem is addressed by separating the melting pot from the injector components. The metal is transferred

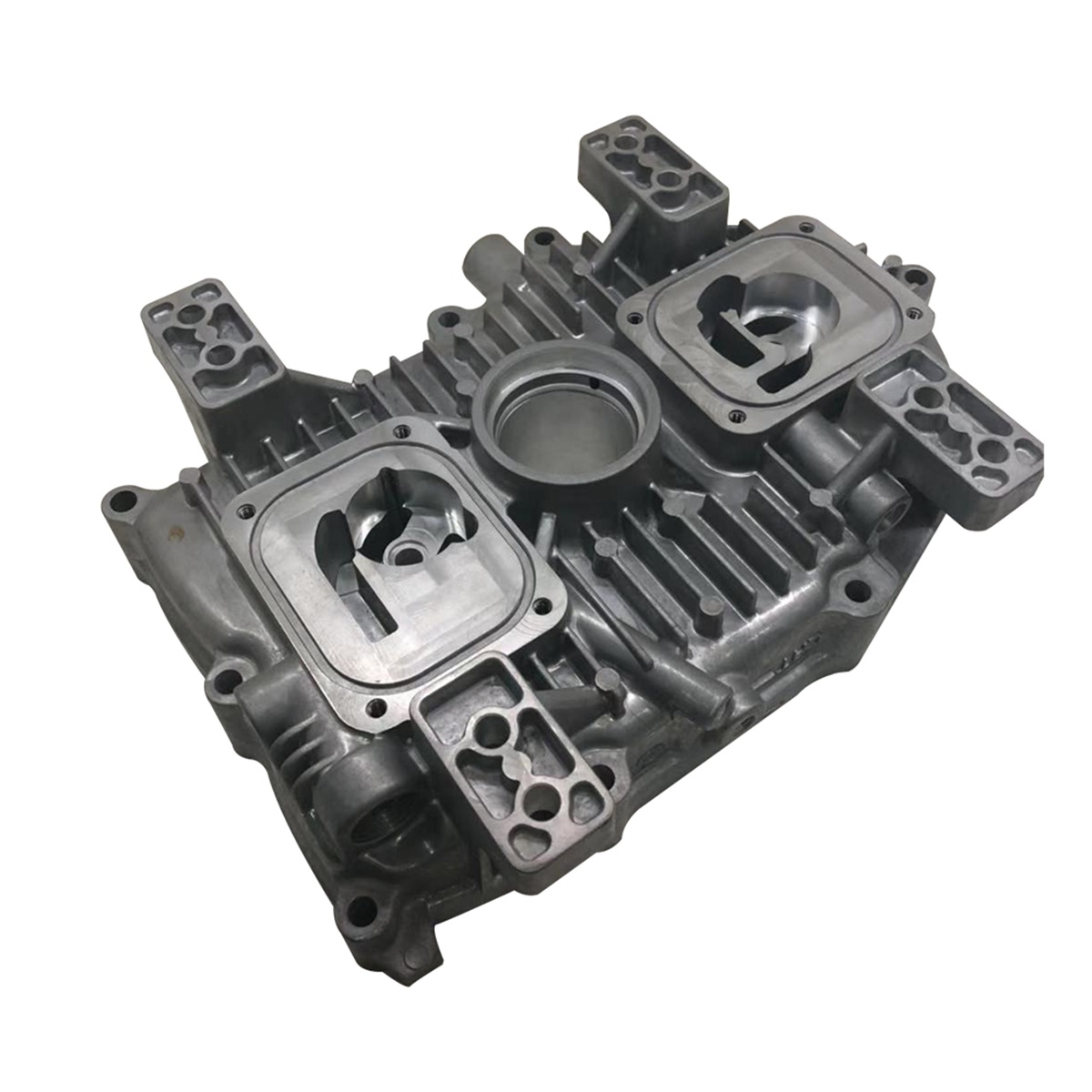

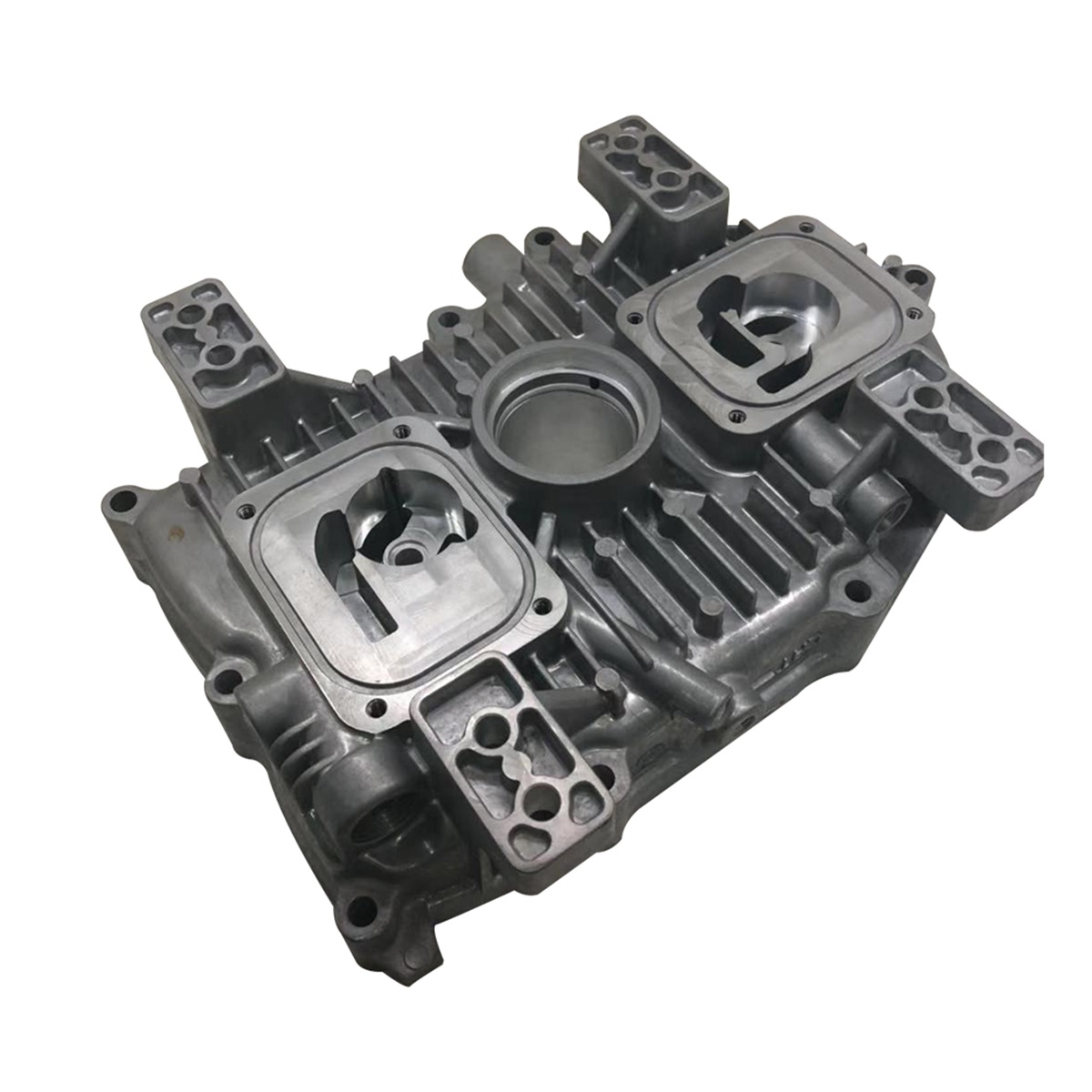

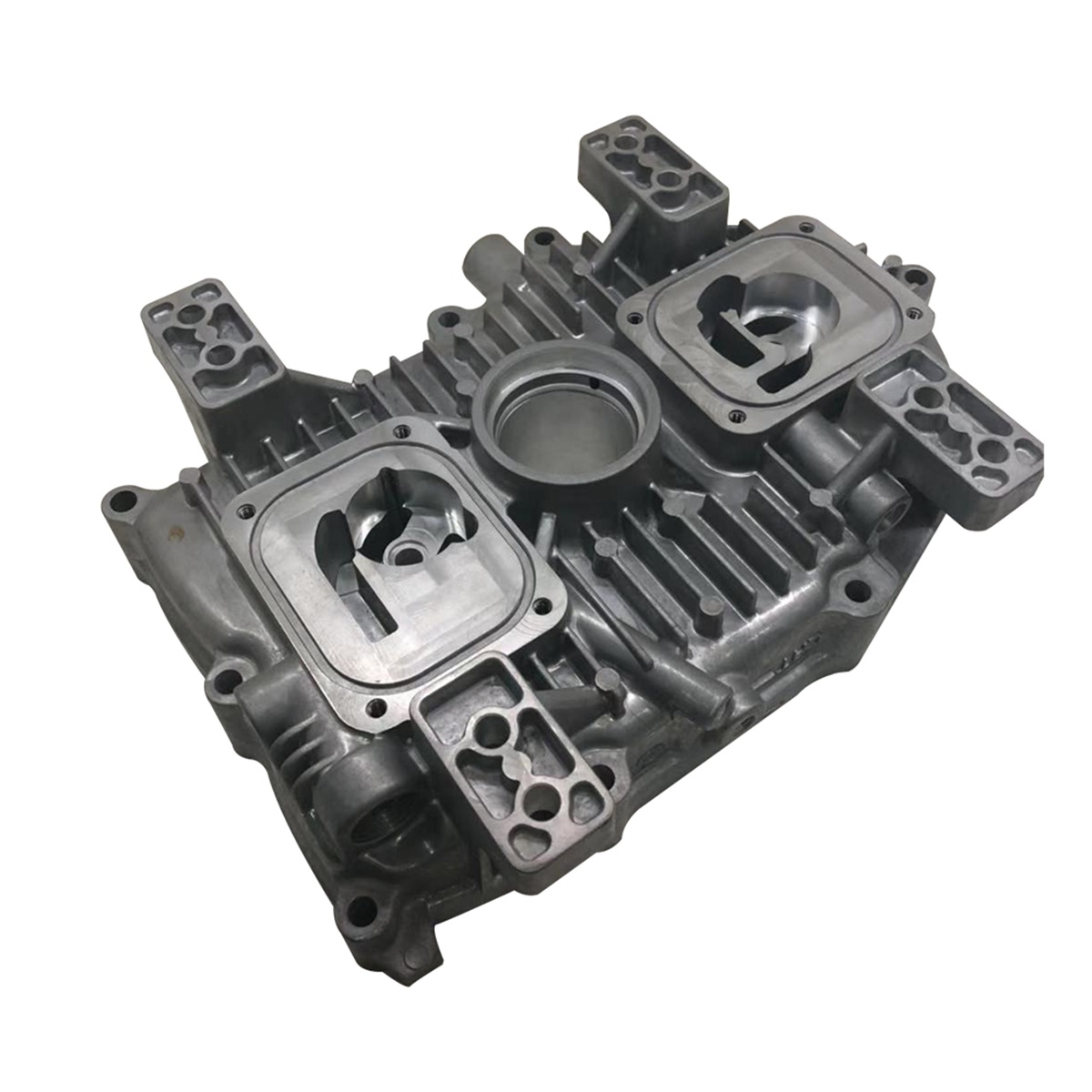

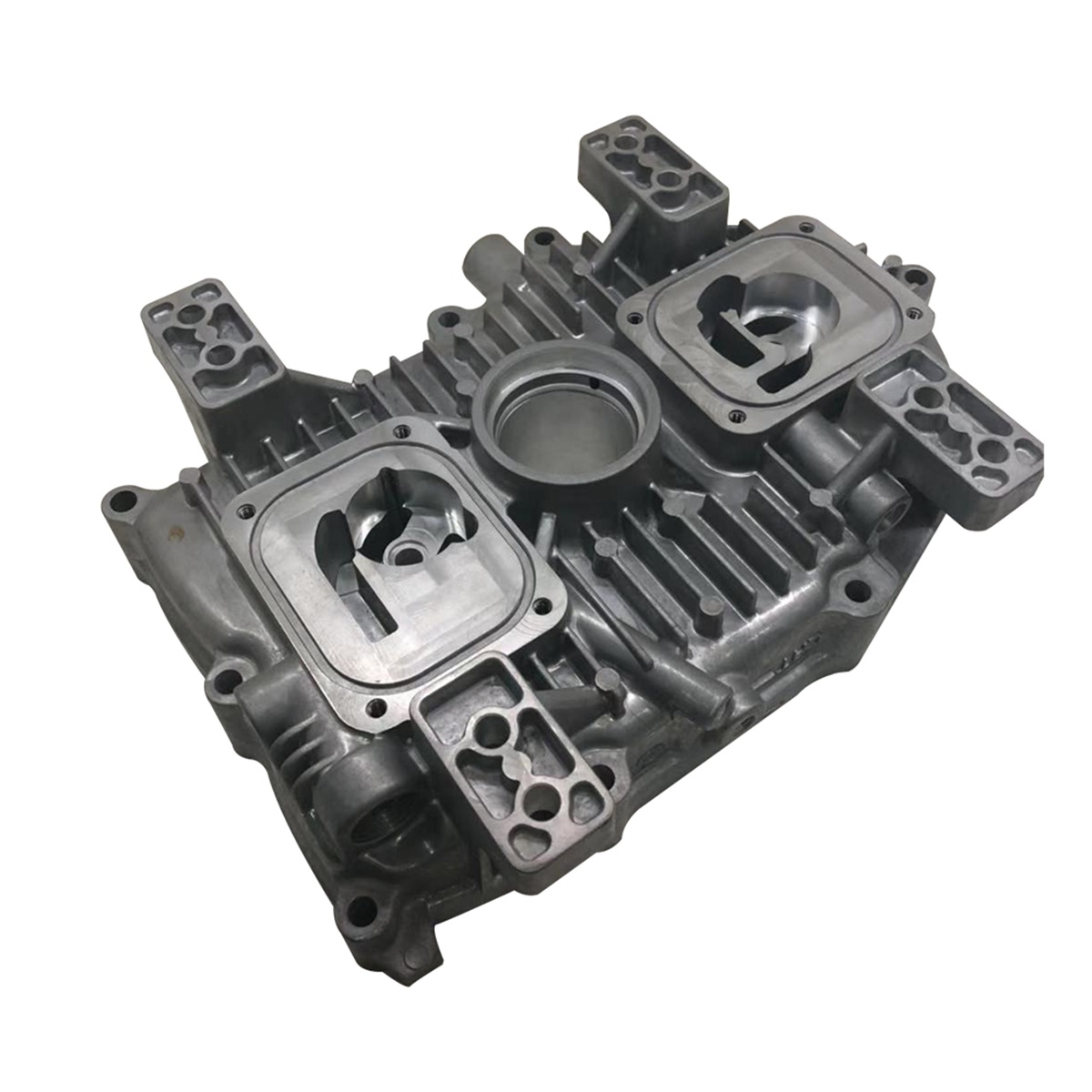

Understanding Die-casting Die casting is the method of producing metal components in which molten material is poured or forced into the mold cavity under extreme

Ferrous metals are primarily distinguished from other types of metals by their iron content. They contain iron as a major component, which gives them specific

This process is fully automated. It helps reduce labor costs and increase product efficiency. So the CNC machines (computer numerical control machines) shape the die,

While ferrous metals are widely used due to their strength and cost-effectiveness, they also come with several disadvantages that can affect their suitability for certain

What is aluminum a380 alloy? In die casting, aluminum A380 alloy helps make complex parts with high precision. It is primarily aluminum, with silicon (Si)

Ferrous metals offer several advantages that make them highly valuable for use across various industries. Here are the main benefits: Ferrous metals, like steel and

3-Axis CNC Milling Machine The most common and the one with the most possibilities. It will be used to control the movement of the cutting

Precision-machined components are critical in numerical platforms that require accuracy, dependability, and high-quality applications. Aluminum CNC machining is typically the most popular for making complex,

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.