Hot Rolling Process

Hot rolling is a fundamental metalworking process where metal is plastically deformed above its recrystallization temperature. This key differentiator from cold rolling allows the metal to

Hot rolling is a fundamental metalworking process where metal is plastically deformed above its recrystallization temperature. This key differentiator from cold rolling allows the metal to

Automotives A lot of heat-treated parts are used in the automotive industry for their strength. Some of these parts are: Gears Crankshafts Axles These

There are several methods and techniques of quenching. Each significantly affects the final properties of your finished material. Let us cover common media for quenching

Cold drawing is a critical metalworking process that involves pulling a material through a single, or a series of, progressively smaller dies at room temperature (or slightly elevated,

The main reason for quenching is to enhance hardness and strength. When you heat your material to the critical temperature, partial or complete austenizing takes

Processes like casting or bending can often affect the structure. So, annealing is used to fix these small defects and align the structure. Three key

Sand casting is one of the most versatile and widely used metal casting processes. Its key advantage is its ability to cast a enormous range

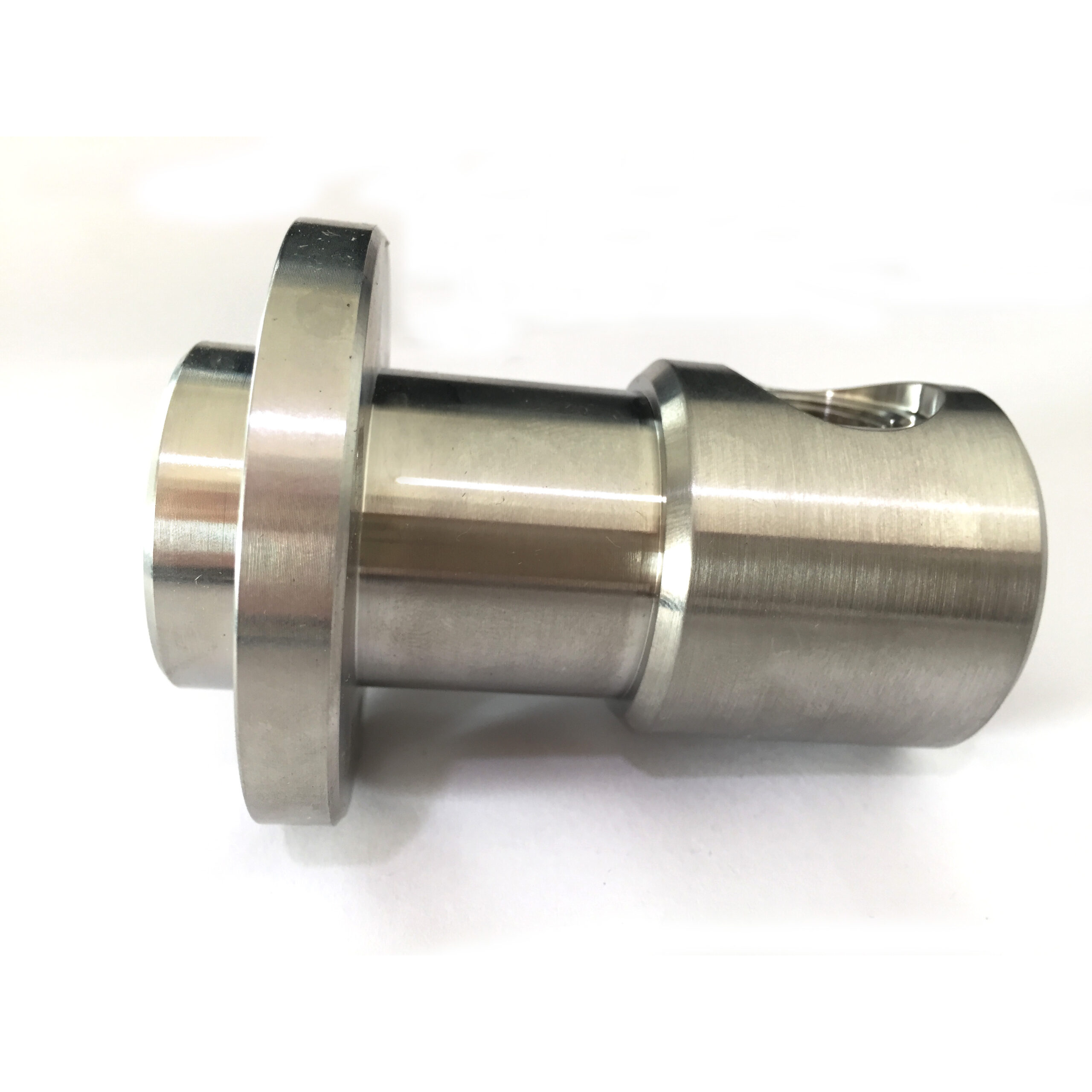

A production drawing (also known as a mechanical engineering drawing or blueprint) is the universal language between designers and manufacturers. For custom metal parts, clarity,

Most factories use special equipment and tools to control the heat treatment processes. Furnaces There are different kinds of furnaces used in the heat

Forging is a manufacturing process where metal is shaped using localized compressive forces, typically from a hammer or die. This process aligns the metal’s grain

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.