Here’s a comprehensive overview of metal 3D printing, covering key technologies, processes, materials, and applications:

- Core Terminology

Metal Additive Manufacturing (AM)

Direct Metal Printing

Metal 3D Printing

- Primary Technologies

1. Powder Bed Fusion (PBF)

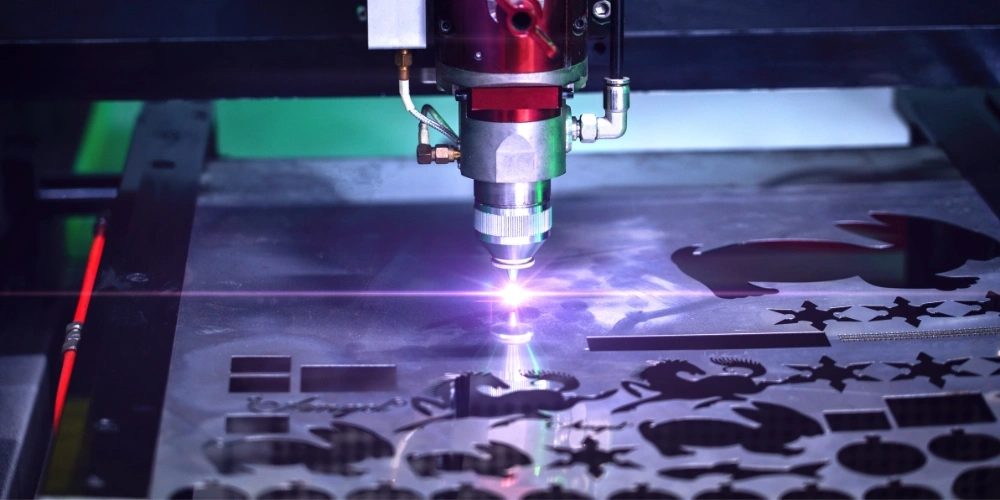

Selective Laser Melting (SLM)

Fully melts metal powder layer-by-layer using a high-power laser.

Produces near-fully dense parts (≥99.9%).

Common for reactive metals (Ti, Al).

Direct Metal Laser Sintering (DMLS)

Partially sinters powder (below melting point).

Ideal for alloys (e.g., Inconel, tool steel).

Electron Beam Melting (EBM)

Uses an electron beam in a vacuum chamber.

High-temperature process for titanium superalloys.

2. Directed Energy Deposition (DED)

Laser Engineered Net Shaping (LENS)

Blows metal powder through a nozzle, melted by laser.

Used for repairs and large components.

Wire Arc Additive Manufacturing (WAAM)

Melts metal wire via electric/plasma arc.

Cost-effective for large aerospace structures.

3. Binder Jetting (BJ)

Deposits liquid binder onto powder bed.

“Green parts” require sintering and infiltration (e.g., bronze).

High build speeds, low cost per part.

4. Material Jetting (MJ)

NanoParticle Jetting (NPJ)

Jets nanoparticles suspended in fluid.

Post-sintering achieves full density.

III. Key Process Steps

Design: CAD model → STL file slicing.

Build Preparation:

Inert gas purging (Argon/Nitrogen for PBF/DED).

Powder spreading (PBF) or wire/powder feeding (DED).

Printing: Layer thickness: 20–100 μm (PBF), 0.5–5 mm (DED).

Post-Processing:

Support removal (manual/CNC).

Hot Isostatic Pressing (HIP): Eliminates internal voids.

Heat treatment (stress relief, aging).

Machining/polishing for dimensional accuracy.

- Materials

| Material Category | Examples | Key Applications |

| Titanium Alloys | Ti6Al4V (Grade 5, 23) | Aerospace, medical implants |

| Nickel Superalloys | Inconel 718, 625 | Jet engines, gas turbines |

| Stainless Steels | 316L, 17-4PH | Tooling, marine components |

| Aluminum Alloys | AlSi10Mg, Scalmalloy® | Automotive lightweighting |

| Tool Steels | H13, Maraging Steel | Molds, cutting tools |

| Precious Metals | Gold, Silver | Jewelry, electronics |

- Applications

Aerospace: Turbine blades, fuel nozzles (GE’s LEAP engine).

Medical: Custom orthopedic implants, dental crowns.

Automotive: Lightweight brackets, heat exchangers.

Energy: Nuclear fusion components, heat-resistant parts.

Tooling: Conformal cooling channels in injection molds.

Defense: On-demand spare parts for military equipment.

- Advantages vs. Limitations

| Advantages | Limitations |

| ▶ Complex geometries (lattices, internal channels) | ◉ High equipment cost ($200k–$2M+) |

| ▶ Mass customization (patient-specific implants) | ◉ Limited build size (typically < 500mm³) |

| ▶ Material efficiency (near-zero waste) | ◉ Surface roughness (Ra 5–30 μm) |

| ▶ Rapid prototyping → production transition | ◉ Intensive post-processing required |

| ▶ Lightweighting via topology optimization | ◉ Certification challenges in regulated sectors |

VII. Emerging Trends

Hybrid Manufacturing: Combining AM with CNC machining.

AI/ML: Real-time defect detection (e.g., porosity monitoring).

Multi-material Printing: Graded structures (e.g., Cu-Stainless transitions).

Sustainability: Recycling metal powder, energy-efficient processes.

Automation: Lights-out factories with robotic post-processing.

VIII. Design for Metal AM (DfAM)

Rules:

Minimize supports (self-supporting angles >45°).

Avoid trapped powder (design escape holes).

Optimize thermal stress (symmetrical shapes).

Software:

Topology optimization (nTopology, Altair).

Lattice generation (Materialise Magics).