Is CNC machining rapid prototyping?

In the world of manufacturing, there are a variety of ways to create prototypes. Perhaps the most well-known method is rapid prototyping, which uses additive manufacturing processes to create three-dimensional models from CAD files. CNC machining is another popular method, which involves using computer-controlled tools to shape materials into the desired form. So, is CNC […]

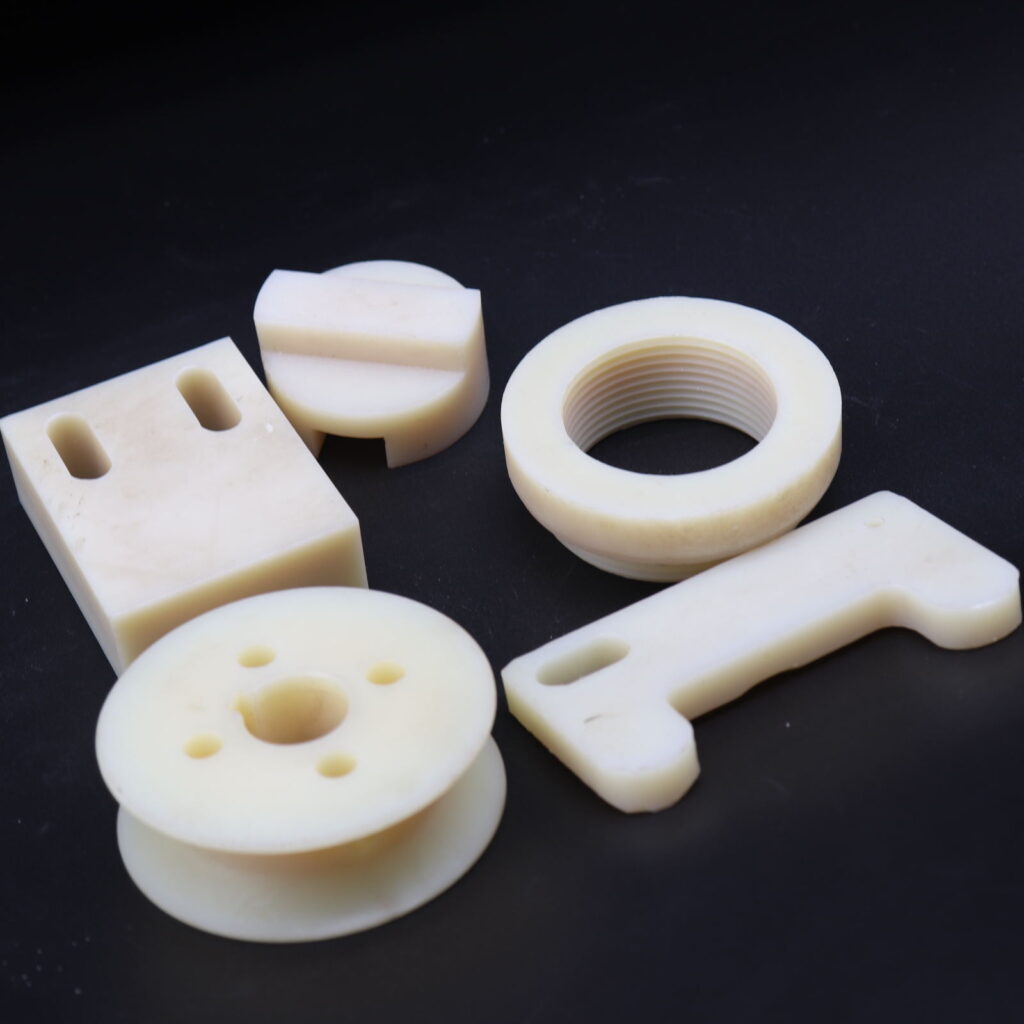

3D Printing Materials

The selection of material is a critical factor in 3D printing (Additive Manufacturing), as it directly determines the functional properties, mechanical performance, aesthetic quality, and application suitability of the printed object. The range of available materials has expanded dramatically, moving far beyond basic plastics to include metals, ceramics, composites, and biomaterials. Here is a detailed […]

What is rapid prototyping?

When we say “rapid prototyping”, it is a procedure that will let you produce a part rapidly and examine the capability and the possibility of error prior to ultimate fabrication. It can also be completed using different practices like CAD, 3D printing, CNC machining, etc. CNC Rapid Prototyping is a well-known method (also known […]

How to Custom Stainless Steel CNC Machining Parts?

Custom ordering stainless steel CNC machining parts involves a straightforward process. Firstly, clearly define the specifications, including material grade and dimensions. Following this, identify reputable manufacturers with specialized expertise in stainless steel CNC machining. Reach out to these manufacturers, providing them with detailed requirements and requesting quotations. Collaborate with the chosen manufacturer to select […]

Powder Metallurgy Manufacturing Process

Powder Metallurgy (PM) is a highly efficient, near-net-shape manufacturing process used to produce complex, precise, and high-performance metal components. It involves the production of metal powders, their consolidation into a desired shape (compaction), and heating (sintering) to create a solid, cohesive part. The core process is often summarized as Blend – Press – Sinter, but encompasses […]

Types of Stainless Steel Suitable for CNC Machining

A myriad of stainless steel classifications proves fitting for the realm of CNC machining: 303 Stainless Steel(SUS303): Acclaimed for its notable machinability. 304 Stainless Steel(SUS304): Universally employed, showcasing commendable machinability, corrosion resistance, and weldability. 316 Stainless Steel(SUS316L): Manifesting exceptional corrosion resistance, well-suited for rigorous environments. 17-4 PH Stainless Steel: Possessing heightened […]

Advantages of CNC Machining Stainless Steel Parts

Engaging Computer Numerical Control (CNC) technology in the fabrication of stainless steel components presents a paradigm shift in manufacturing. The precision excellence inherent in CNC, propelled by automated algorithms and stringent tolerances, amplifies the overall caliber of the end product. This integration also ushers in heightened operational efficiency, where automated procedures, rapid tool transitions, and […]

Factors of Customizing CNC Stainless Steel Parts

Material Grade: Opt for the apt stainless steel classification contingent on sought-after attributes like resistance to corrosion and hardness. Design Complexity: Scrutinize the intricacy of the component’s design to ascertain CNC machining’s efficacy in achieving the desired forms. Precision and Tolerances: Articulate with precision the requisite tolerances and exactitude levels for the meticulous […]

Stainless Steel Machining

Machining stainless steel presents a formidable challenge due to its unyielding nature, resilience, and inclination to undergo work hardening. Nonetheless, a variety of Computer Numerical Control (CNC) technologies exhibit prowess in the art of stainless steel machining. The following elucidates some prevalent CNC manufacturing processes applied in the machining of stainless steel: CNC Milling: […]

Types of Parts Do Different CNC Machining Techniques Best Serve

Depending upon the features and needs of different parts, a precise CNC machining technique is used accordingly. Milling because of its versatility is perfect for complex as well as contoured parts such that it would fit into engine blocks, molds and even aerospace structure. Therefore, while turning does well on cylindrical parts such as […]