Precision Manufacturing for Large and Heavy-Duty Components

In industries where performance is measured in both precision and power, the ability to manufacture large-scale, heavy-duty components is a true test of a supplier’s technical capability and logistical expertise. At Juize Machinery, our expertise extends beyond precision parts into the realm of large-format and heavy-section manufacturing, where we combine robust equipment, engineering rigor, and project […]

Advantages of OEM CNC Machining Service

OEM CNC Machining Service offers a multitude of advantages that make it a preferred choice for many industries seeking precision and efficiency in manufacturing processes. Let’s explore some key benefits: Precision Excellence: Leveraging CNC technology, OEM CNC machining ensures meticulous accuracy, meeting exact specifications for components. Cost-Efficiency: Outsourcing to OEM services provides cost […]

Applied Industry of CNC Metal Parts

Applications of CNC metal parts are huge and wide ranging from the aerospace, automotive to medical devices, electronics industry even across oil & gas manufactures products defense instrument super communication mixed energy constructing water vehicles consumer resources as well guy food manufacturing mining environmental connected ongoing lines. CNC, precision machined metal parts play essential functions […]

The Value of Design Support in Custom Manufacturing

Moving a product from initial concept to a reliable, cost-effective component requires more than advanced machinery—it demands early and informed collaboration. At Juize Machinery, we believe that the most successful custom parts are born from a partnership that starts long before production. Beyond our capabilities in casting, forging, machining, stamping, and specialty processes like heat […]

CNC Machining Cost

There are many factors that affect the cost of CNC machining. Next, we will analyze the cost of CNC machining from several main aspects. 1. Equipment: The cost of use, maintenance, and labor of advanced machine tools are higher. In general, the hourly machining cost of a 5-axis machine is 2-3 times that of […]

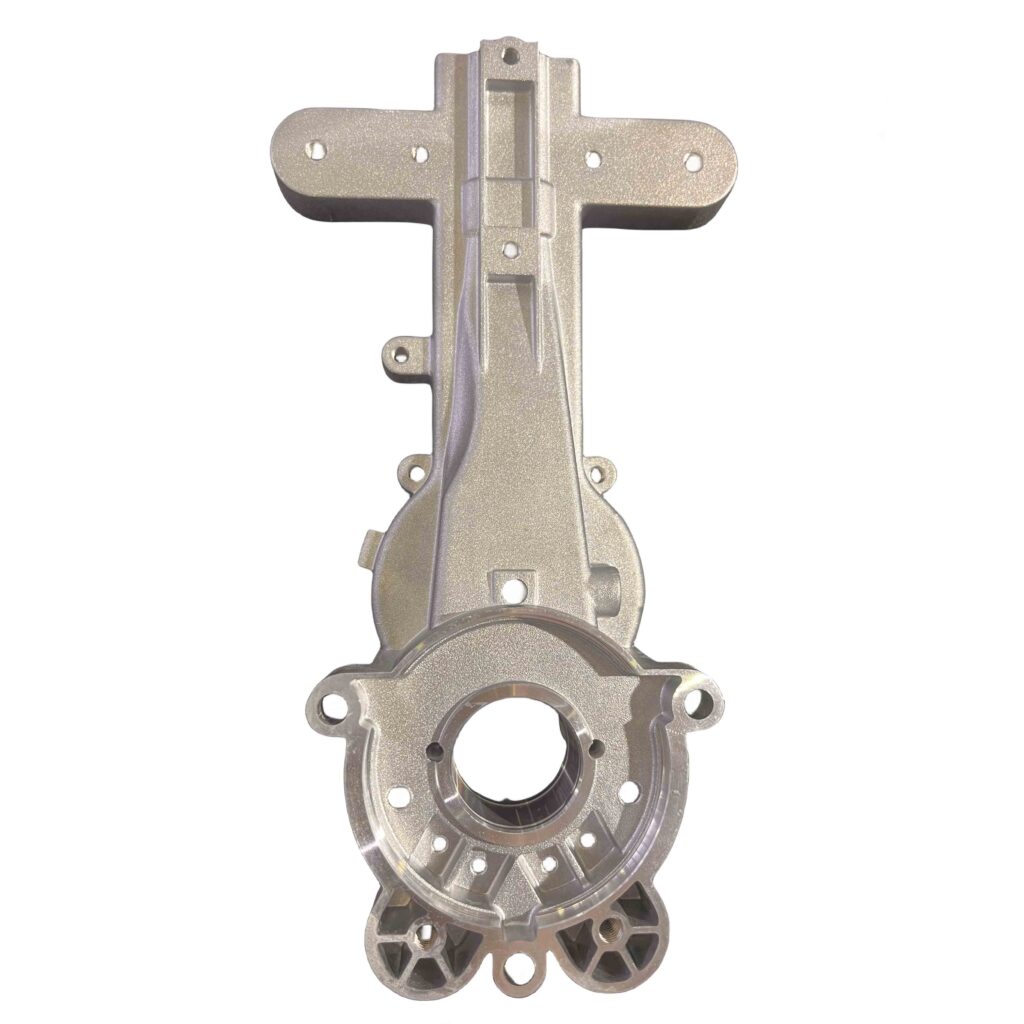

Advanced Manufacturing for Demanding Components

In an era where product innovation often hinges on component complexity, the ability to produce intricate, high-precision parts is what separates industry leaders from the rest. At Juize Machinery, we specialize in transforming challenging designs into reliable, manufacturable realities. Leveraging our multi-process capabilities—from casting and forging to precision machining and stamping—we provide integrated solutions for […]

Importance of CNC Machining

CNC technology can process complex design parts on various materials with extreme precision, which is the foundation of modern industry and cutting-edge scientific and technological exploration. Today’s state-of-the-art CNC machine tools rely on hydrostatic guides and laser interferometers to achieve extremely high precision in the nanometer range, and are the only option for processing nanoscale […]

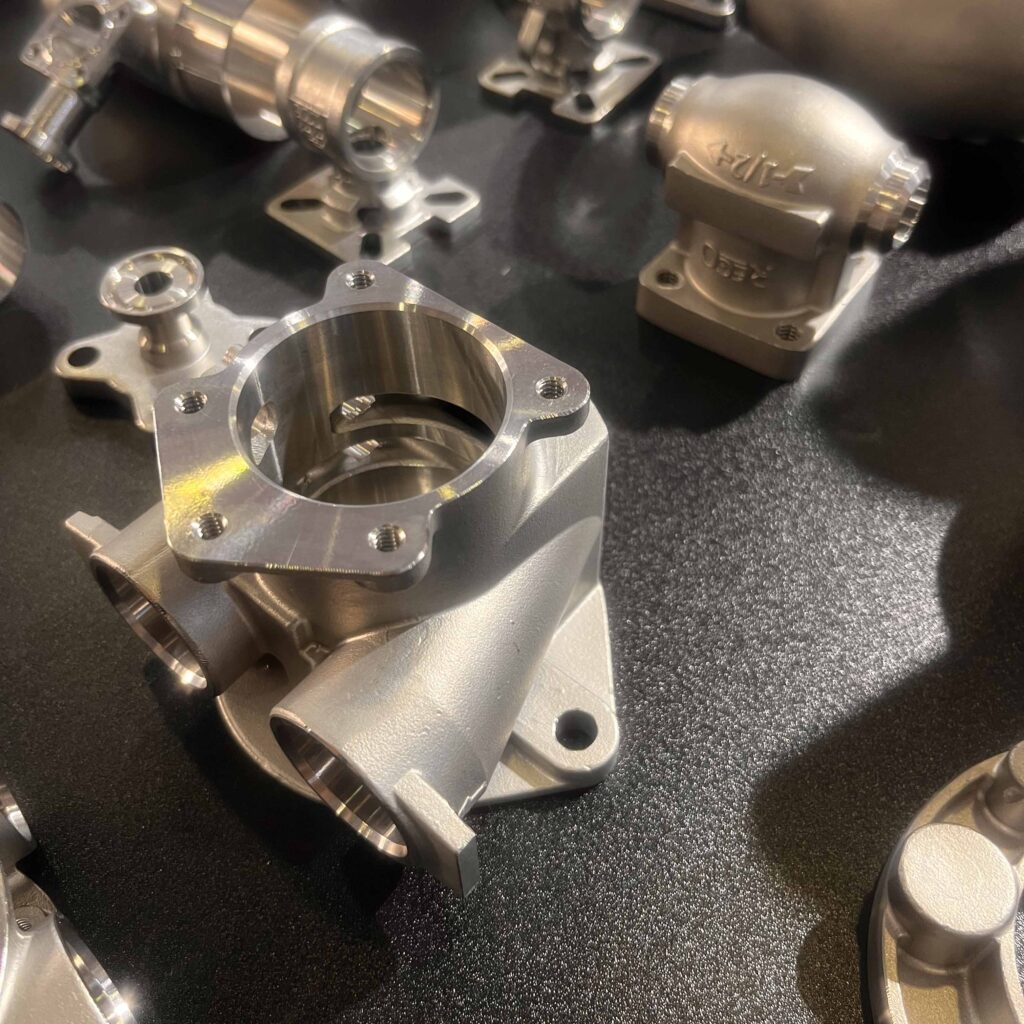

Beyond the Surface: How Advanced Finishing Elevates Metal Component Performance

In the world of precision manufacturing, the journey of a part does not end when it leaves the machine. Its surface—the final frontier—plays a decisive role in durability, functionality, and aesthetics. At Juize Machinery, our expertise extends beyond core processes like machining, casting, and stamping. We provide advanced surface finishing solutions that transform quality components into high-performance, […]

The Critical Role of Heat Sinks in Modern Electronics

As electronic devices become more powerful and compact, managing heat has transformed from a technical consideration into a fundamental requirement for reliability and performance. At Juize Machinery, we understand that effective thermal management isn’t just an add-on—it’s integral to product design and longevity. Beyond our established expertise in casting, forging, and machining, we have developed […]

What Does CNC Prototyping Mean?

In the simplest of terms, CNC prototyping is a type of machining process that is used before producing or manufacturing a single piece or a small batch of a product. The necessity of CNC prototyping lies within the effectiveness and efficiency of a product. Let’s say that your product has successfully been market researched […]