Stainless steel used in CNC Machining

Stainless steels are enhanced by the addition of elements such as chromium, nickel, molybdenum and nitrogen to increase their corrosion resistance for specific environments. According to the metallographic organization, stainless steel can be roughly divided into three types: austenitic stainless steel (non-magnetic), ferritic stainless steel (strongly magnetic) and martensitic stainless steel (strongly magnetic). Among […]

Navigating Material Selection: The Foundation of High-Performance Components

The journey toward a reliable and cost-effective custom part begins with a critical, yet often challenging, decision: material selection. This choice fundamentally dictates the component’s performance, manufacturability, lifespan, and total cost. At Juize Machinery, we recognize that our expertise extends beyond shaping metal—it encompasses guiding our partners through the complex landscape of material science. As a Gold Verified […]

The Integrated Advantage: How Multi-Process Manufacturing Drives Value

In the landscape of modern industrial sourcing, the fragmented supplier model—where components journey through multiple specialized shops for casting, machining, and finishing—increasingly reveals its hidden costs: extended lead times, communication gaps, compounded logistics, and diffused accountability. At Juize Machinery, we champion a more efficient, reliable, and value-driven alternative: fully integrated, multi-process manufacturing. As a Gold Verified Supplier on […]

Carbon steel used in CNC Machining

Carbon steel is divided into low carbon steel (C≤0.25%), medium carbon steel (C 0.25%~0.6%) and high carbon steel (C≥0.6%) according to the carbon content. On the contrary, the lower the content, the lower the hardness, and the easier it is to process. Carbon steel has high density (about 7.8g/cm³) and high strength, after years […]

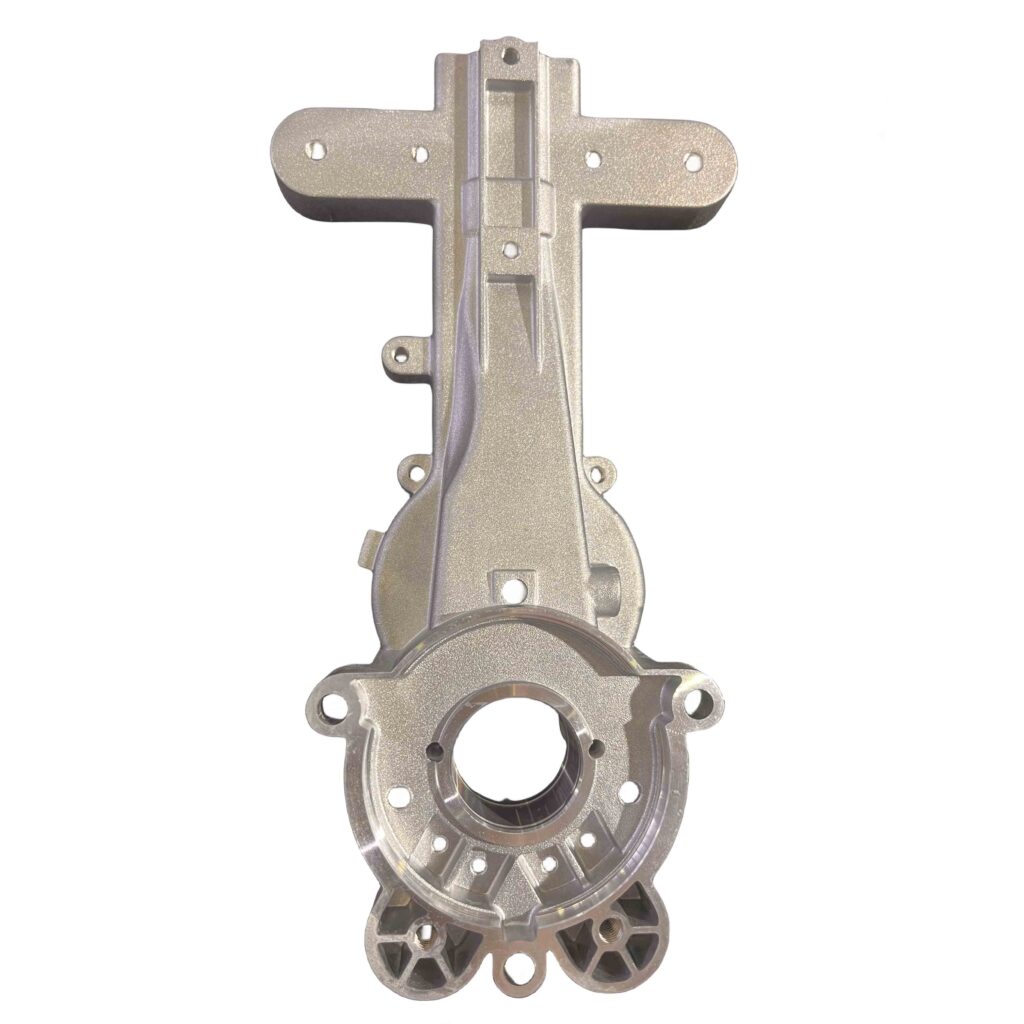

Aluminum alloy used in CNC Machining

Such as 6061 and 7075, are commonly used materials, with a density of 2.7-2.8g/cm³, very light, only about 40% of steel. High strength, but poor fatigue resistance and high temperature resistance, usually used in various casings or structural components. The frame of your phone, camera, or computer may be made from a single piece of […]

From Components to Growth: Partnering for Your Product’s Success

In today’s competitive market, selecting a manufacturing partner is a strategic decision that directly impacts your product’s performance, cost, and speed to market. The right partner does more than machine parts to print—they become an integral contributor to your product’s success. At Juize Machinery, we view our role through this lens. As a Gold Verified Supplier […]

Copper Used in CNC Machining

Copper is widely used in electronic and mechanical fields because of its excellent ductility, electrical conductivity and thermal conductivity. Commonly used models are: C11000 (Pure Copper), H62 (Cu-Zn Alloy, Brass), QSn6.5-0.1 (Bronze). Pure copper has good plasticity, but this will also lead to serious sticking during cutting, chips are not easy to break, and […]

Building Resilient Supply Chains: The Value of a Stable Manufacturing Partner

In an era marked by global uncertainty and supply chain volatility, the reliability of your manufacturing partner has become as critical as the quality of the parts they produce. Disruptions in material flow, unexpected delays, and inconsistent capacity can jeopardize your production schedules and market opportunities. At Juize Machinery, we recognize that true partnership extends […]

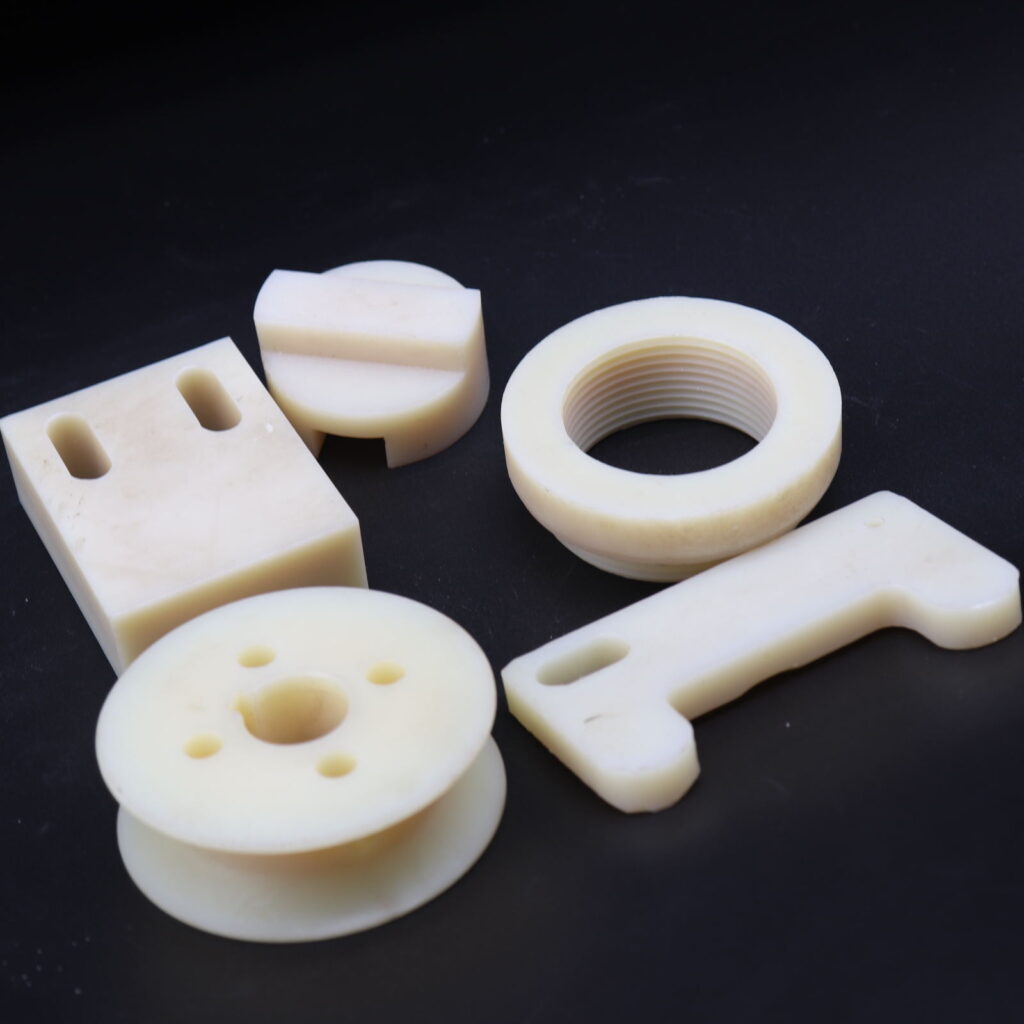

Plastics in CNC Machining process

Traditional plastic processing methods such as injection molding and blow molding require high mold manufacturing costs. CNC machining is ideal for plastic prototype part verification or low-volume production. But CNC technology can only process plastics with a certain hardness, and it can’t do anything in the face of softer materials like silicone. Common CNC machined […]

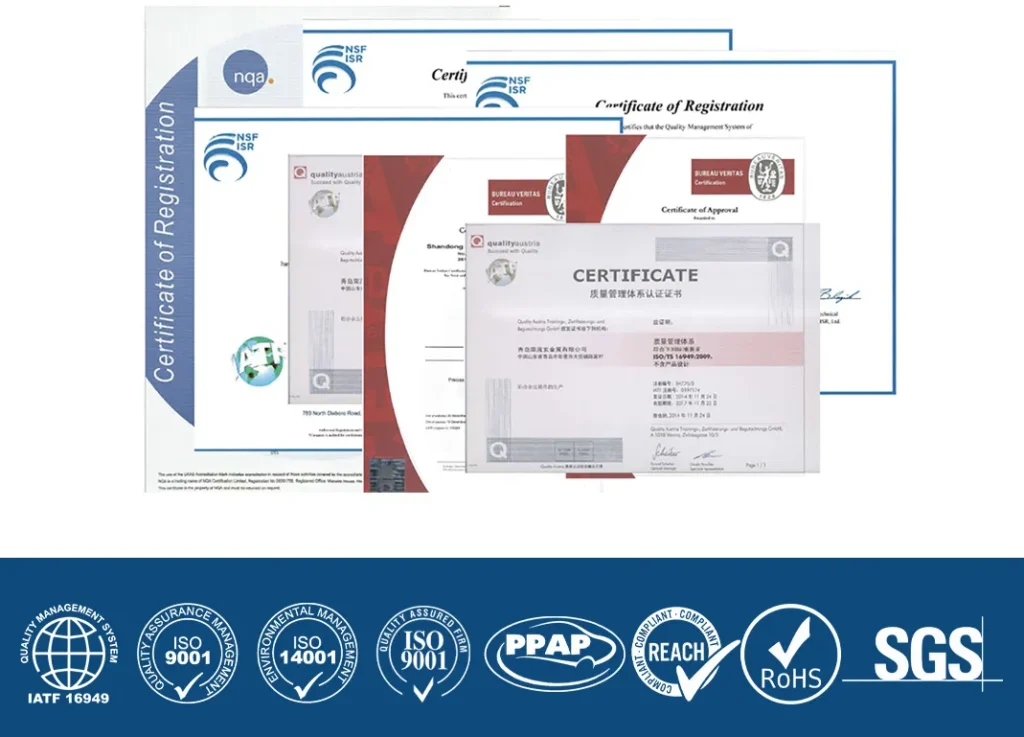

The True Meaning of “Quality”: Beyond the Certificate – Our Verification Process

In manufacturing, “quality” is often referenced but rarely fully unpacked. It is more than a final inspection sticker; it is a promise embedded in every step of the process. At Juize Machinery, our status as a Gold Verified Supplier on Alibaba is a reflection of this deeper commitment—a commitment validated not by a single certificate, but by […]