Limitations of Weldability in Metals

Welding is a complex fabrication process that relies on the ability of materials to be joined through coalescence. While many metals are weldable, certain inherent material properties can make welding difficult, impractical, or even impossible. The concept of “weldability” refers to the ease with which a metal can be welded to produce a sound joint […]

Types of Centrifugal Casting

True Centrifugal Casting Symmetric hollow parts are the result of true centrifugal casting. Additionally, it revolves around a central axis. The mould spins rapidly. It typically falls between 300 and 3000 rpm. The inner surface has no core and is only shaped by centrifugal force. This technique effectively shares cylinders, bushings, pipes, and tubes. […]

Process of Centrifugal Casting

Mold Preparation Molds are cleaned and examined, and any contaminants from previous casts are removed from the mold. Refractory coatings applied to the mold surface prevent the metal from sticking, and prolong its life. The next step is preheating the mold to a temperature that avoids thermal shock when the metal contacts the surface […]

The Correct Usage of VCI Bags

VCI bags are effective for preventing rust. They utilize Volatile Corrosion Inhibitor (VCI) technology to protect metals during storage or transport. When used correctly, they can provide protection for up to 2 years. Here is a quick guide to the correct usage of VCI bags: Step Key Action Important Tips 1. Preparation Ensure the metal […]

Advantages of Centrifugal casting

Stronger Parts Hollow Parts Made Easy Better Quality To get the best results, you must focus on two main things: spin speed and machine position. The mold must spin at the right speed. Fast molding can change the metal’s structure. Similarly, too slow mold will remain empty.

What is an Interference Fit?

In the world of mechanical engineering and precision manufacturing, an Interference Fit (also known as a Press Fit or Friction Fit) is a crucial type of connection between two components. It is a fundamental concept for creating strong, permanent, and precise assemblies without the need for fasteners or adhesives. The Core Principle: More Hole, Less Shaft At its simplest, an […]

What is Centrifugal Casting?

Centrifugal casting is a smart way to make parts using spin. You pour hot, liquid metal into a mold that spins very fast. The outward push, called centrifugal force, spreads the metal evenly onto the mold’s walls. This force also pushes heavier, good metal outward and lighter flaws inward.

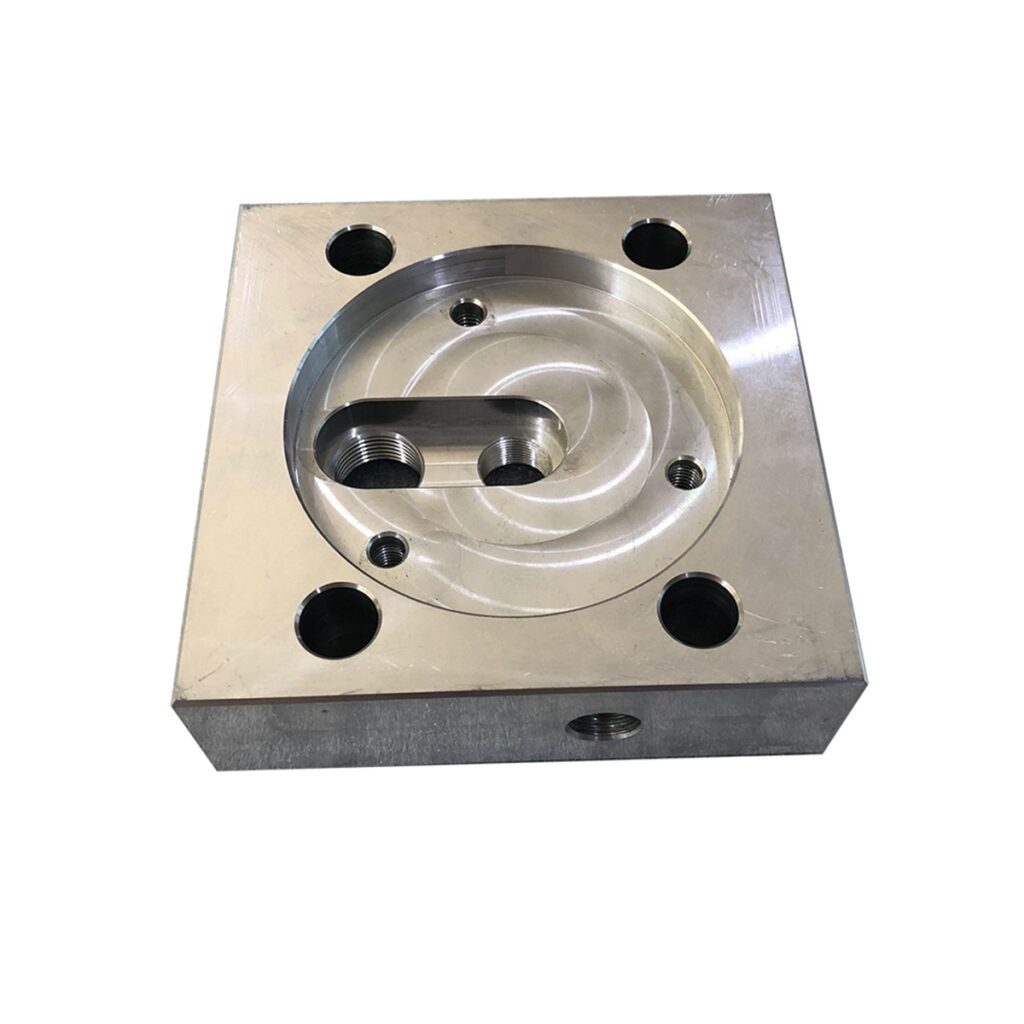

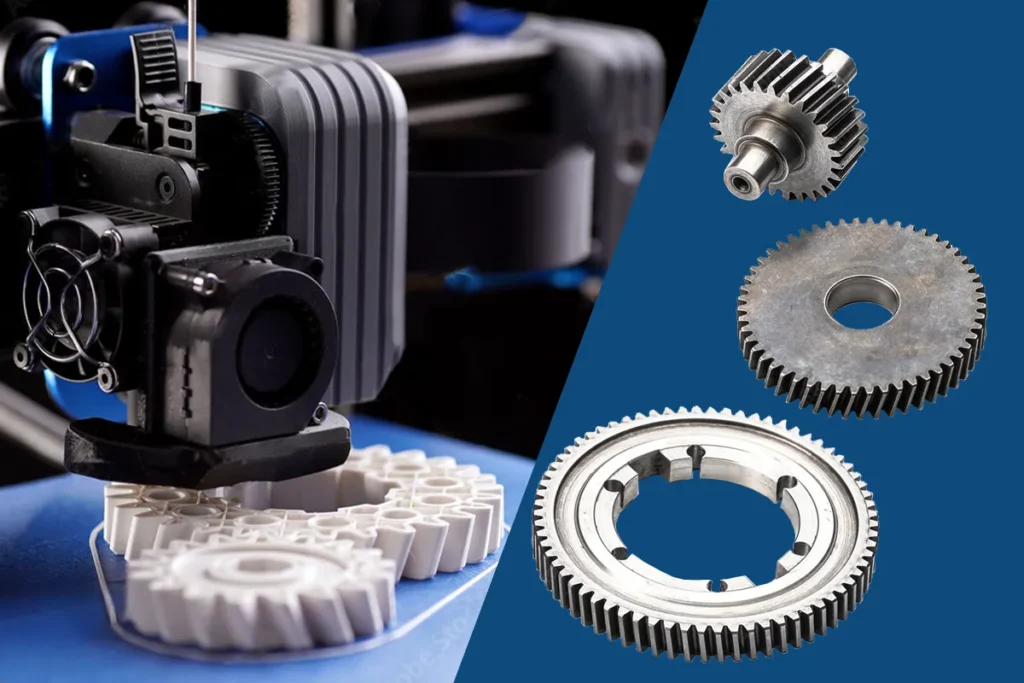

The Crossroads of Metal Fabrication: A Strategic Guide to Low-Volume vs. High-Volume Production

You’ve finalized your design and need custom metal parts. The first and most critical question isn’t “what material?” but “how many?” The choice between low-volume and high-volume production isn’t just about quantity; it’s a fundamental decision that impacts cost, timeline, design flexibility, and the very technology used to bring your part to life. Navigating this […]

Applications of the lost foam casting

The LFC process explores its charm in a number of industries owing to its ability to produce complex shapes with quite accuracy. Automotive Industry: You can deploy this process to produce the Engine blocks, cylinder heads, gear housings, and suspension components. Aerospace Industry: Furthermore, the LFC process finds its applications in Lightweight structural […]

Lost-Foam Casting vs. Sand Casting: What’s the difference

Lost-Foam Casting Sand Casting Pattern Material · Uses expanded polystyrene (foam), which evaporates during metal pouring. · Uses a solid reusable pattern made of wood, plastic, or metal. Mold Type · Unbonded dry sand supports the foam pattern. · Green sand (a mixture of sand, clay, and water) forms the mold. Pattern Reusability · […]