End Milling

End milling is the most versatile milling operation among all, as the cutter used has actually cutting edges on both ends or sides. Thus, you can use it to produce pockets, slots, or even contours in the workpieces. Well! You can imagine it like a drilling machine, but the difference is that a drilling machine […]

Peripheral (or Plain) Milling

If we talk about the peripheral milling, then you can say it’s the opposite of the face milling. This is because, unlike face milling, here the cutter is placed in an axis parallel to the workpiece. As a result when the cutter rotates then it would actually remove material from the sides or edges of […]

Reduction of Area (RA): A Measure of Material Ductility

The Reduction of Area (RA) is a fundamental, quantitative measure of ductility obtained from a tensile test on a material specimen. It expresses the extent to which a material can plastically deform (i.e., stretch) in a localized region before it fractures. 1. Definition Reduction of Area is defined as the percentage decrease in the cross-sectional area of a tensile […]

Face Milling

Face milling is a beloved process in manufacturing industries as it is actually used to smooth the uneven surfaces. Here actually, the cutter moves in an axis perpendicular to the workpiece ( stationery or slowly moving). You can also control the depth & feed rate of this cutter. As a result, when the cutter spins, […]

Anodizing: A Guide to the Electrochemical Process

Anodizing is an electrochemical process that converts a metal surface into a durable, decorative, corrosion-resistant, and wear-resistant anodic oxide finish. It is most commonly applied to aluminum, but can also be used for other non-ferrous metals like titanium and magnesium. Unlike paint or plating, which add a separate layer on top of the metal, anodizing integrates the protective […]

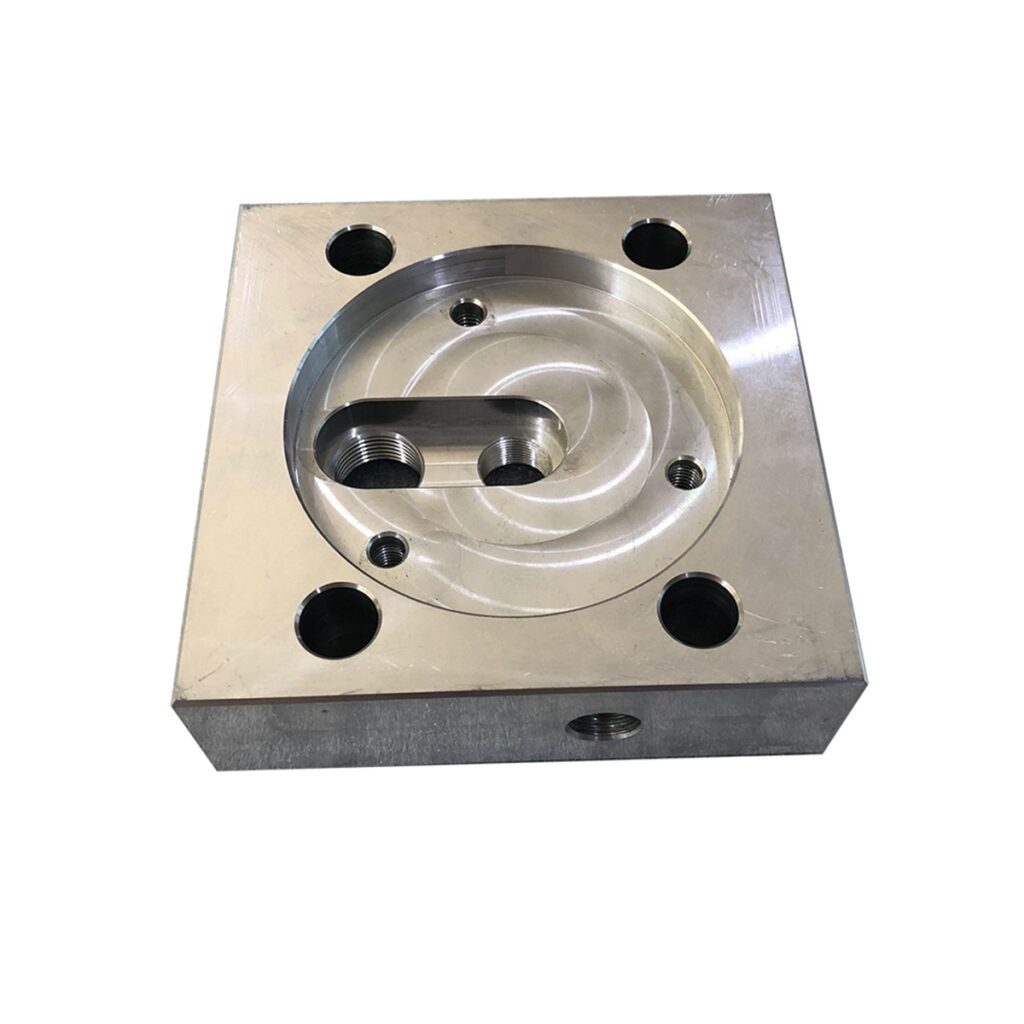

Basics of milling operations

“Milling is actually a type of subtractive manufacturing in which a milling cutter removes material from the workpiece to achieve the required shape.” For your information, the first milling machine was invented by Eli Whitney in 1818 to manufacture rifles for the U.S. government. Well! The working principle of all types of milling machines […]

Electrogalvanizing vs. Hot-Dip Galvanizing: A Comprehensive Comparison

Both electrogalvanizing and hot-dip galvanizing are processes used to coat steel or iron with a layer of zinc to protect it from corrosion. This protection is primarily achieved through two mechanisms: barrier protection (shielding the base metal) and cathodic protection (where the zinc sacrificially corrodes to protect the steel). However, the methods, properties, and applications of these two coatings […]

Metals Commonly Used in Metal Stamping

Various manufacturers use different types of materials and alloys for metal stamping, the most common of which involve, but are not limited to: Aluminum Stainless Steel Low Carbon Steel Copper Brass High-Speed Steel (HSS) The usage of each of these metal types depends on the outcome or the result that the client wants and needs […]

Cold Drawing vs. Hot Rolling: A Comprehensive Comparison

Cold drawing and hot rolling are two fundamental metal forming processes with distinct principles, procedures, and outcomes. The primary difference lies in the temperature at which the metal is processed relative to its recrystallization temperature. 1. Hot Rolling Definition: Hot rolling is a metalworking process where the metal is heated above its recrystallization temperature (typically over 1000°C for […]

Applications of Centrifugal Casting

Centrifugal casting is used in many industries especially that require cylinder shaped parts. Pipe manufacturing for water, oil, and gas distribution depends heavily on this process. These pipes give you excellent pressure resistance. Engine cylinder liners use centrifugal casting to fight against wear resistance and dimensional stability. Meanwhile, bearing bushings are the result of […]