Thread Milling

Thread milling, as the name suggests, is used to create the thread (internal or external spiral ridges) in the workpiece. So, to do this, it uses the roating cutters instead of tapping, thus the cutter moves circularly and downward and produces large threads in the workpiece.

How Heat Treatment Transforms the Mechanical Properties of Metals

Heat treatment is a controlled process of heating and cooling solid metals and alloys to achieve desired mechanical and physical properties, without changing the product’s shape. It fundamentally works by altering the metal’s microstructure—the internal arrangement of its atoms. The core principle is the manipulation of phase transformations, primarily through the control of: Temperature Time at […]

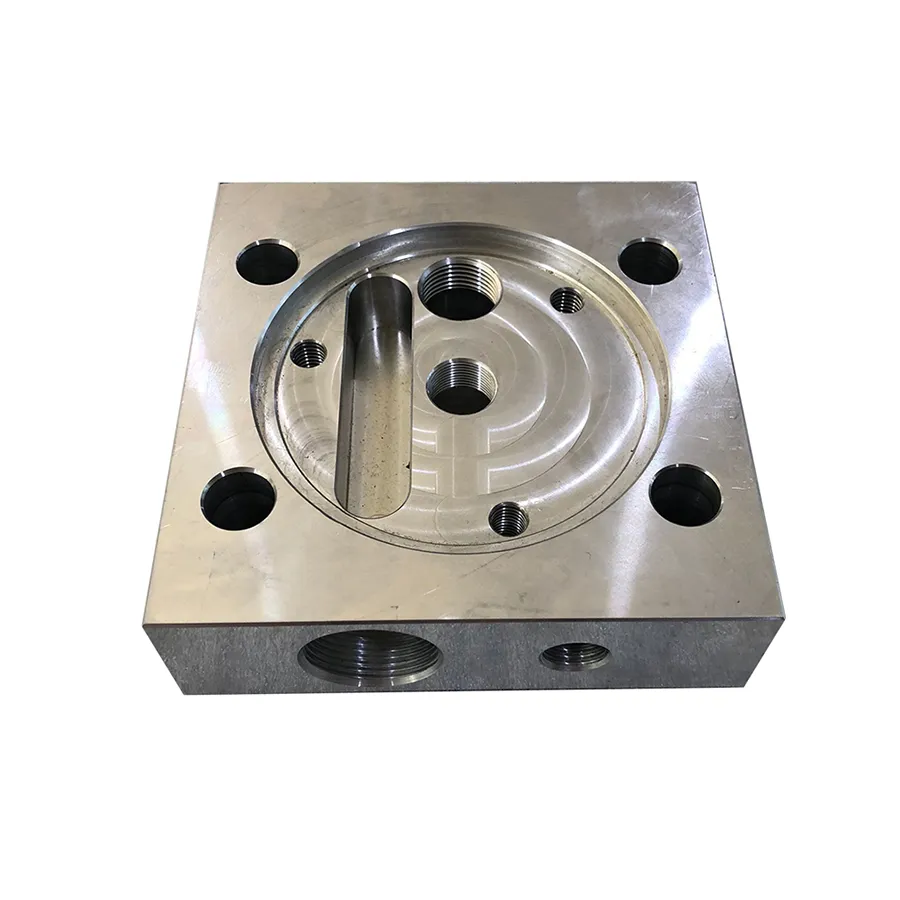

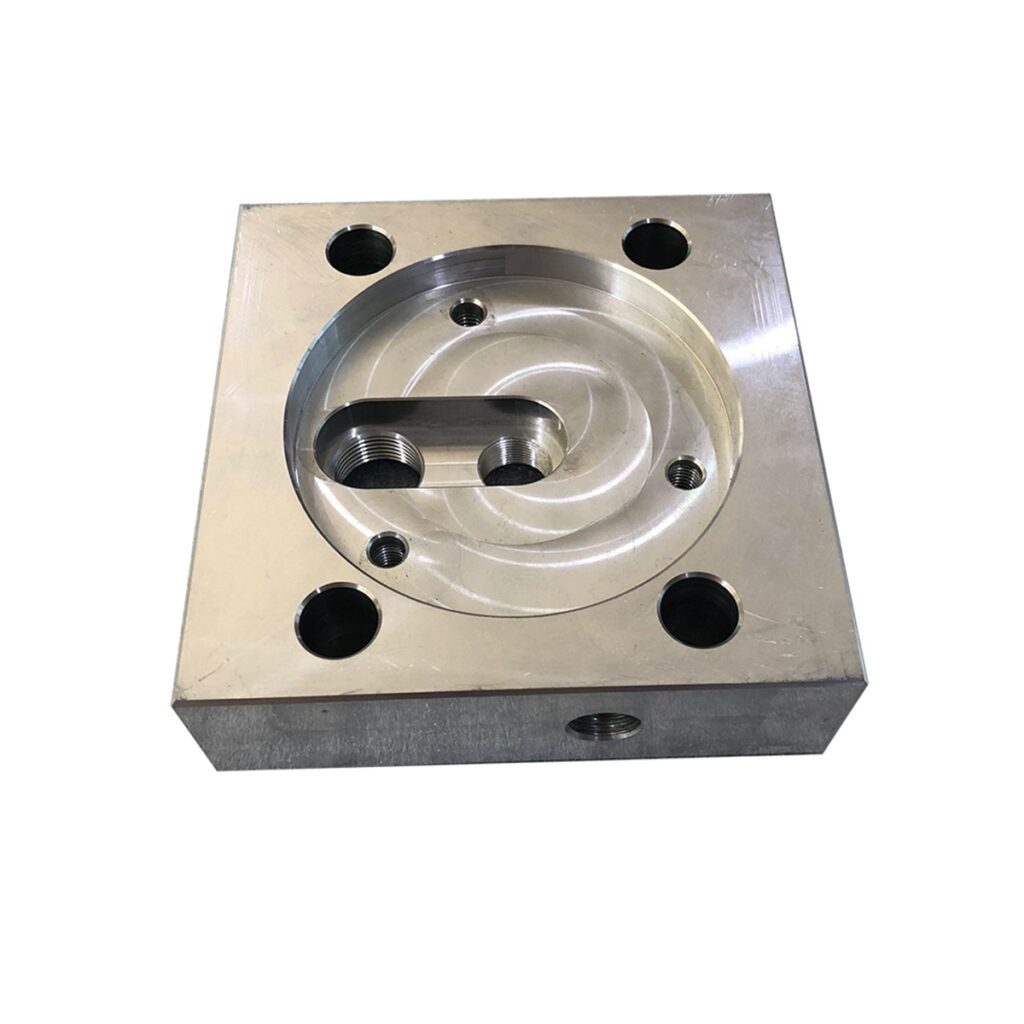

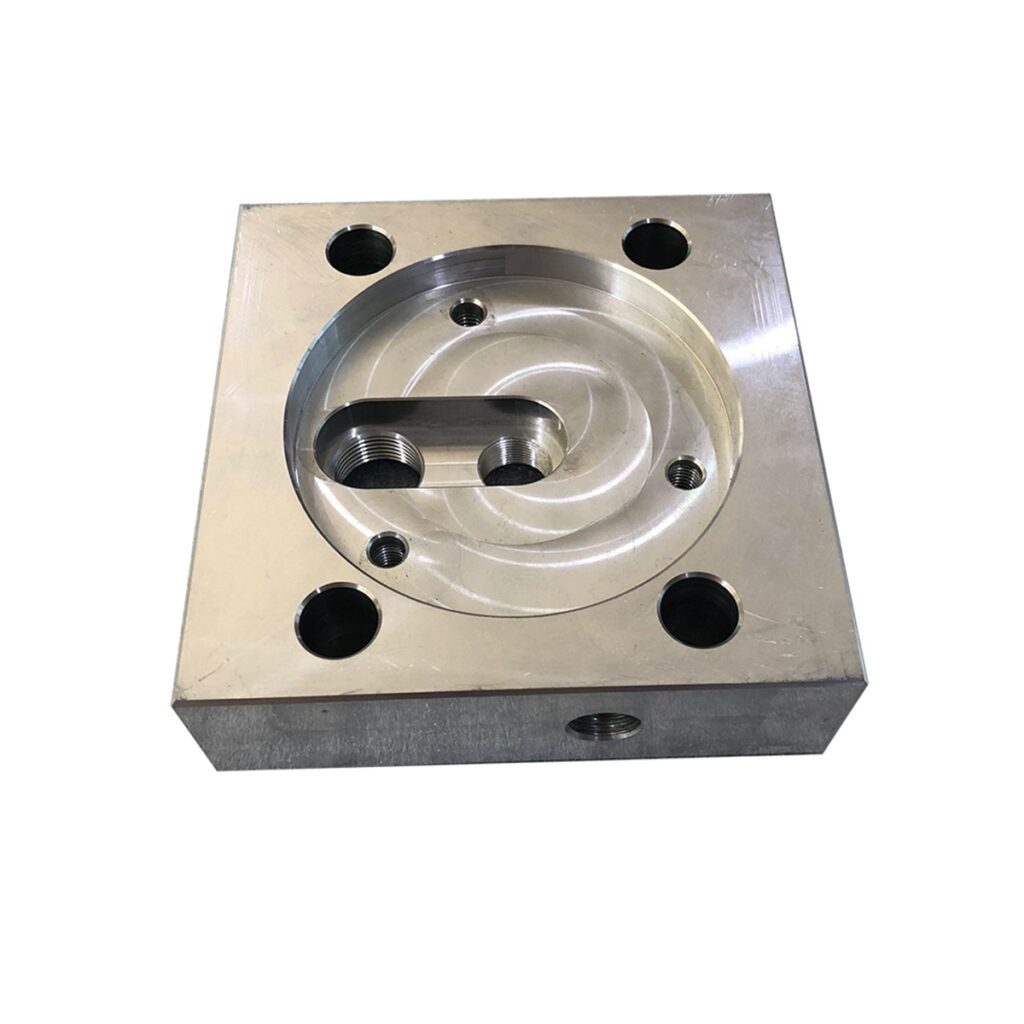

CNC Milling

CNC milling is today’s modern operation in which computer-controlled machines are actually used to automatically perform the cutting processes. Thus you would get highly accurate or precisely shaped complex components, eliminating the chances of any human error. For your information, we at HDC MFG offer customized CNC milling services using four-axis and five-axis machines […]

Mainstream Hardness Scales and Their Conversion

Hardness is a measure of a material’s resistance to localized plastic deformation, such as a dent or a scratch. Unlike properties such as mass or length, hardness is not a fundamental property but is defined by the method of measurement. Consequently, there are numerous hardness scales, each suitable for different materials and applications. Direct conversion […]

Profile Milling

If you want to create complex shapes on your workpiece material, then profile milling would be your go-to. This is because it uses a tool that has multiple cutting edges, which can cut the material along the side or angle according to your desired pattern. Also it has ball tip that moves around to smooth […]

The Yield of a Metal Component

The “yield” of a metal component is a fundamental mechanical property that defines the transition point from elastic to plastic deformation. Understanding this point is critical in engineering design, material selection, and failure prevention. 1. Fundamental Concept: The Stress-Strain Curve The yield behavior of a metal is most clearly understood from its Engineering Stress-Strain Curve, obtained from a […]

Angle (Angular) Milling

On the other hand, in angle milling, you use the specialized milling cutters like tapered one that are flare or cone-shaped but can be adjusted to the desired angle. So, here, you would actually place such cutter at a specific angle relative to the workpiece (not parallel, not perpendicular). So, when the cutter rotates, it […]

Chrome Plating

Chrome plating, also known as chromium plating, is an electroplating process that involves applying a thin layer of chromium onto a metal or plastic object. The result is a surface that is highly valued for its aesthetic appeal, hardness, and corrosion resistance. There are two primary types of chrome plating: Decorative Chrome (Nickel-Chrome): A thin, bright, […]

Slot Milling

As the name suggests, you can use the slot milling operation to carve a channel of any size in the material, which you say like grooves or slots. You can do this job with a slot cutter, which basically looks like a circular saw blade, allowing you to cut the sides of material from the […]

A Comprehensive Guide to 3D Printing Materials

The world of 3D printing has evolved far beyond basic plastics. The choice of material is now critical, as it directly impacts the strength, flexibility, appearance, and functionality of a printed object. Materials are generally categorized by the printing process they are designed for. Here’s a detailed breakdown. 1. Fused Deposition Modeling (FDM) Materials FDM […]