How Aluminum Anodizing Works

To begin the anodizing process, three things are needed: an anodizing tank, a positive electrode (anode), and a negative electrode (cathode). First, the aluminum needs

To begin the anodizing process, three things are needed: an anodizing tank, a positive electrode (anode), and a negative electrode (cathode). First, the aluminum needs

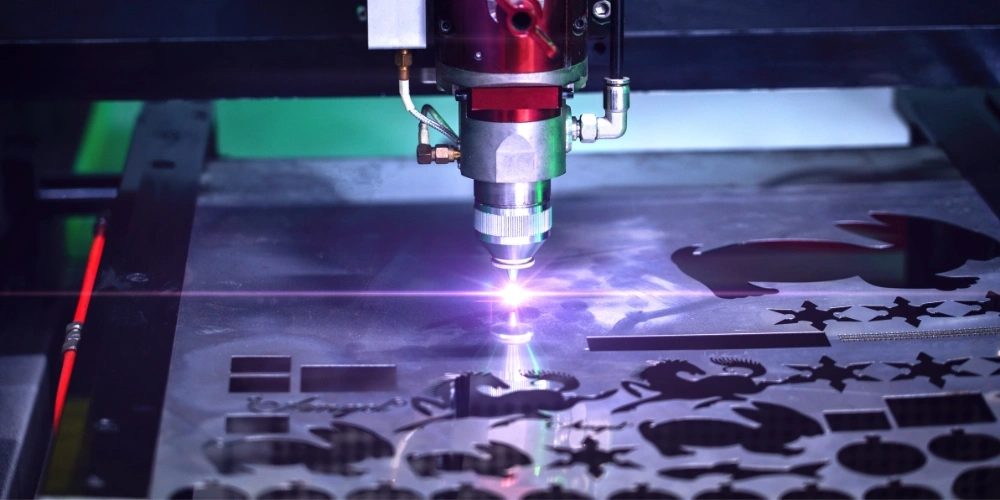

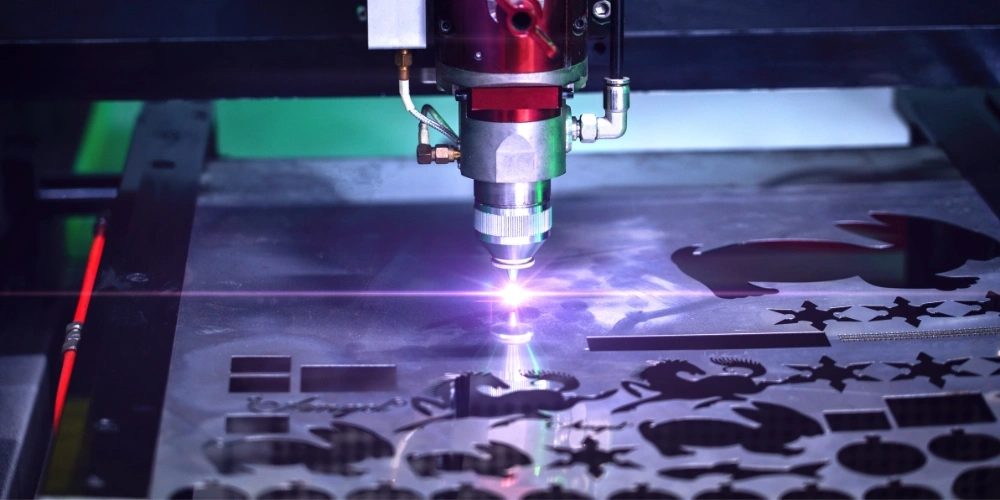

In choosing a laser cutting service, consider experience first; meaning that the provider should own an impressive reputation and necessary qualifications concerning dealing with your

When exposed to the air, aluminum will naturally form a very thin oxide layer that builds up and keeps the material protected, but not for long.

The accuracy of laser cutting services depends on the method of laser cutting used to perform the cutting operations. The gas laser cutters will

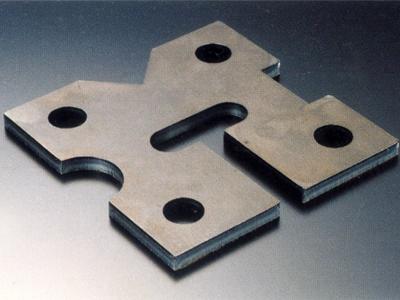

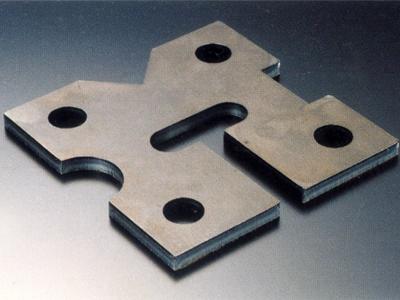

Rapid Tooling Sheet metal can be quickly cut into 2D profile shapes and formed out of a variety of high-strength materials, making it perfect for

For your laser cutting services, you can choose from more than 200 types of materials. The common materials include: Acrylic (clear) Brass (with low hardness)

Standard Minimal post-processing or treatment on parts is done. Bead Blast The part surface is left with a smooth, matte appearance. Anodize (Type

There is a significant margin difference between the laser cutting service compared to service involved with other cutting methods. There are few reasons why laser

Sheet metal fabricators first convert CAD and drawing data into machine code. A laser cutting, waterjet, or plasma cutting machine will then precisely remove sheet

Sheet stock is procured in a flat state and cut then formed into its final state through a series of progressive steps. For a typical

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.