Methods for Detecting and Verifying the Magnetic Field in MT Equipment

Here are the primary methods for detecting and verifying the magnetic field in Magnetic Particle Testing (MT) equipment, as per industry standards (e.g., ASTM E1444/E1444M,

Here are the primary methods for detecting and verifying the magnetic field in Magnetic Particle Testing (MT) equipment, as per industry standards (e.g., ASTM E1444/E1444M,

Here’s a comprehensive guide to selecting metal fabrication methods, focusing on key decision factors: Key Factors Influencing Method Selection: Part Geometry & Complexity: Simple, Constant

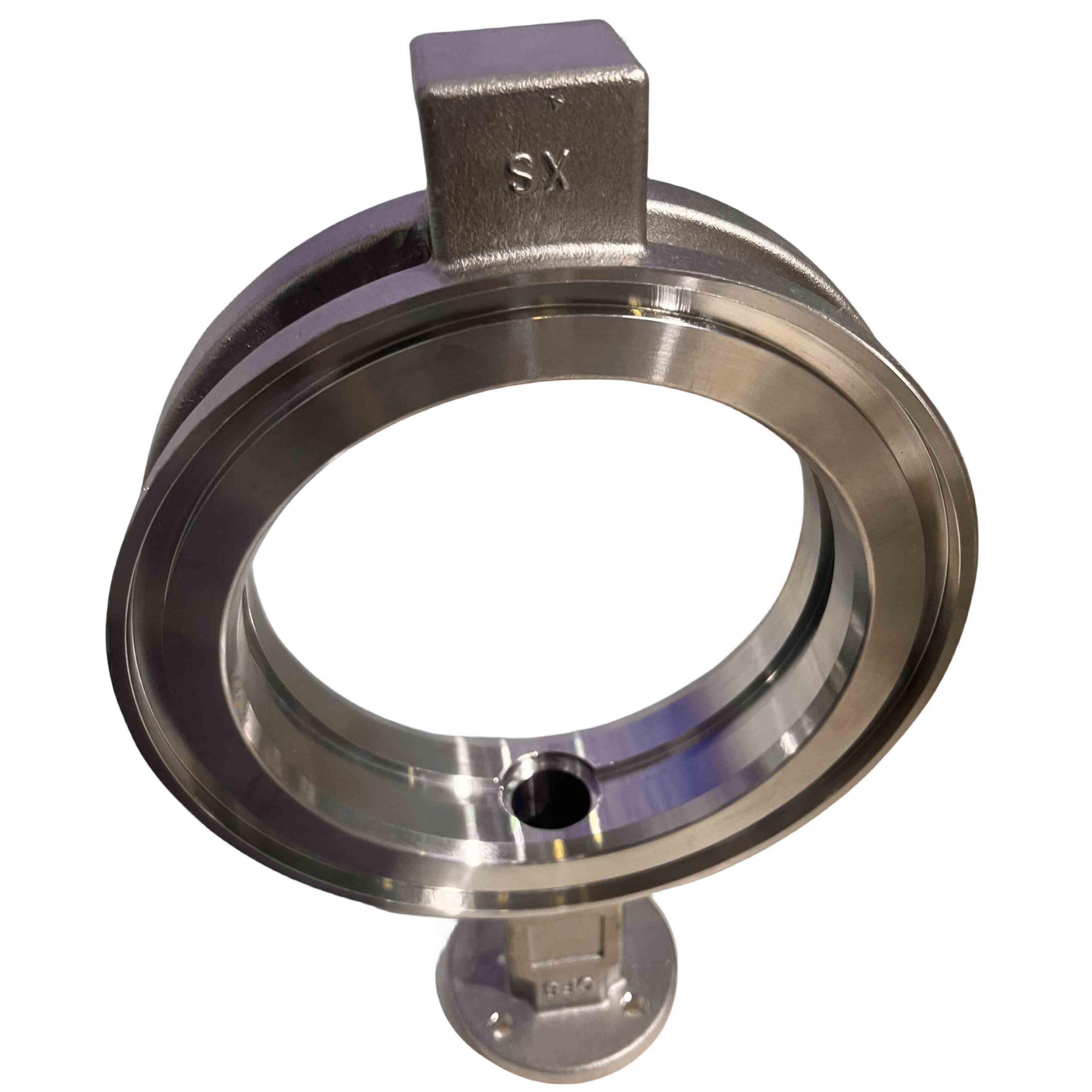

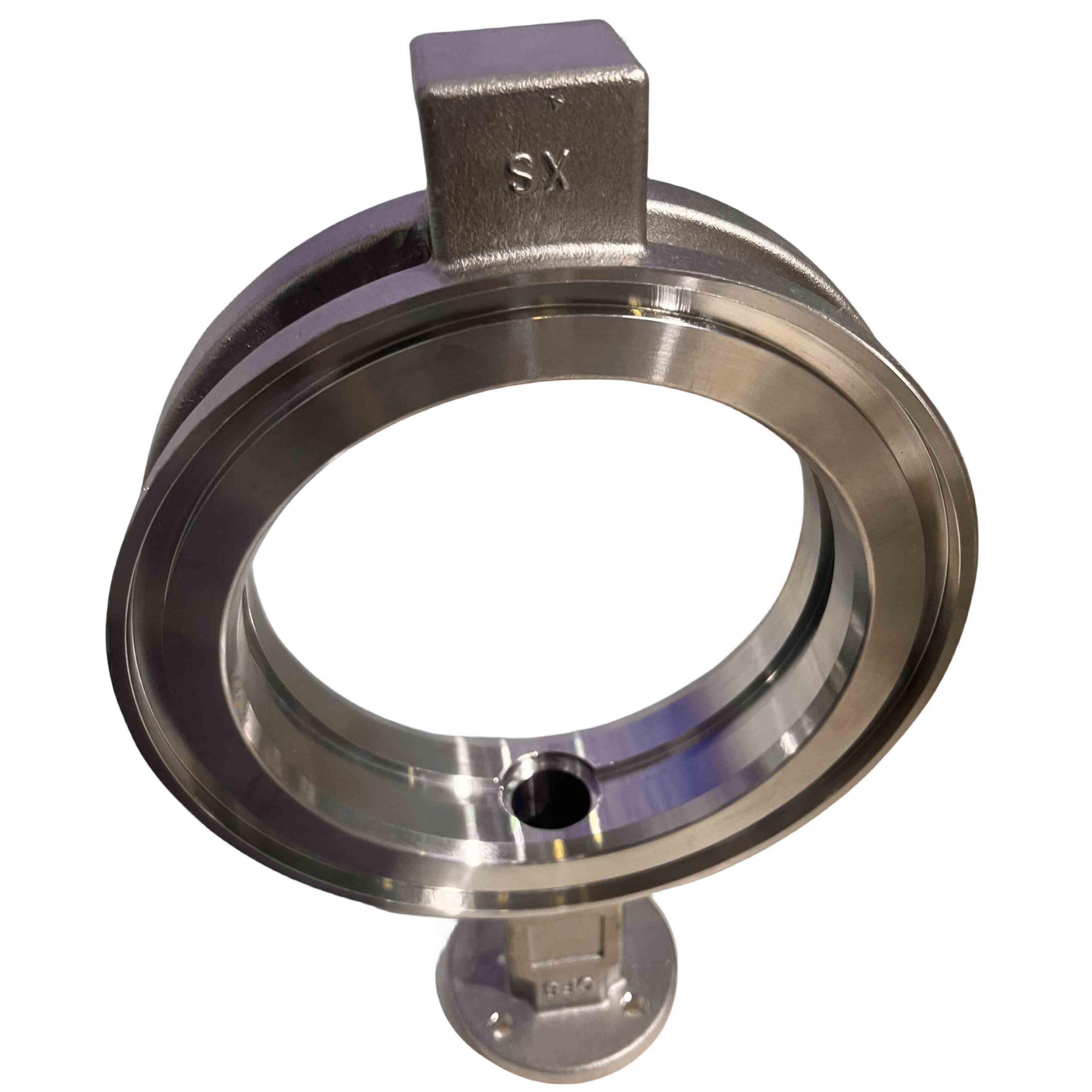

Casting is usually used for intricate parts: Automotive: Parts such as engine blocks, cylinder heads, and brackets are often cast because they have complex

Forging can be used to make very strong parts in different industries: Automotive: Parts like crankshafts, connecting rods are usually made through the forging

Hot Rolling Process: A Comprehensive Overview Hot rolling is a fundamental metalworking process where metal stock (primarily steel, but also aluminum, copper, nickel, titanium, and alloys) is

Cold Drawing: A Precision Metal Forming Process Cold Drawing is a fundamental metalworking process used to reduce the cross-sectional area and increase the length of metal stock (wires,

Feature Forging Casting Grain Structure Forging keeps the grain aligned with the shape of the part, which improves its strength. This forms a new crystalline

Here’s a comprehensive overview of rubber component processing methods: Rubber Component Processing Methods Rubber manufacturing transforms raw elastomers into functional components through distinct stages. Key

Process In the casting process, a metal is heated until it melts. The molten metal is then poured into a mold, which can be made

Here’s a comprehensive overview of metal surface treatment processes, categorized by their primary function and mechanism: Purpose of Surface Treatment: Corrosion Protection: Forming barriers against

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.