Permanent and durable

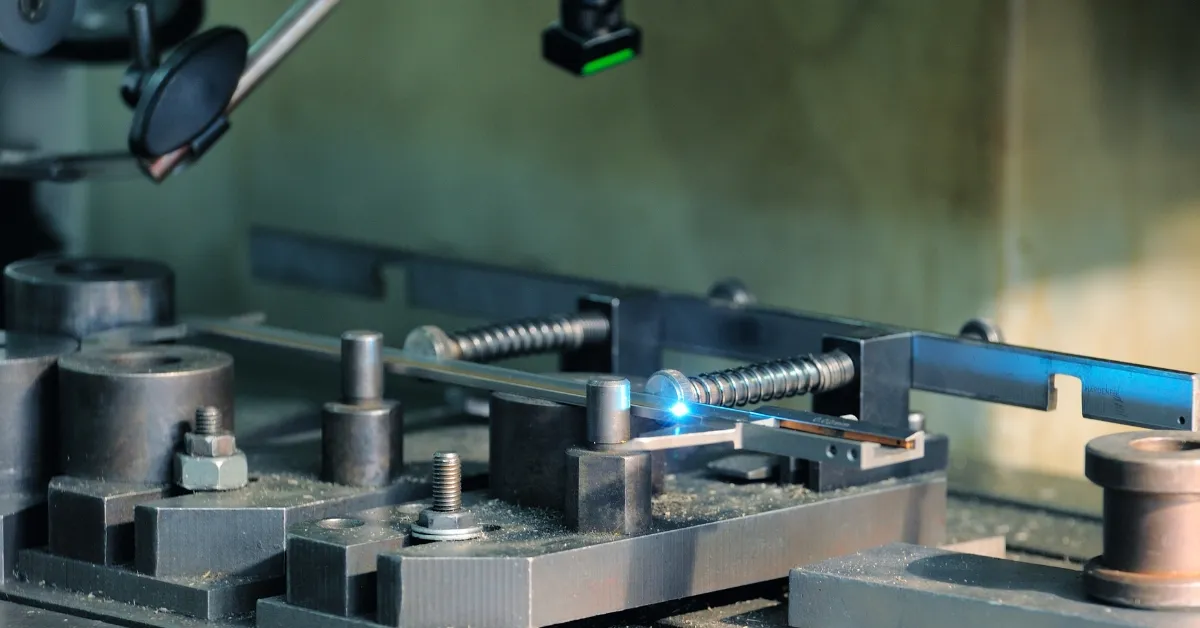

Laser engraving creates marks by melting or vaporizing the designated area of aluminum, rather than simply printing on the material surface.

Therefore, the engraved mark is durable and indelible. Even if the aluminum is subsequently subjected to surface treatment such as anodizing, the mark remains permanent and wear-resistant.

High precision and excellent quality

Laser engraving on aluminum can achieve extremely fine lines( reach micron level) that ensure detailed and intricate pattern designs appear clearly and precisely.

Non-contact and material protection

Aluminum laser engraving uses the thermal energy generated by lasers to accomplish engraving processing, without the need to touch the surface of the parts.

This non-contact protects the integrity of the parts, eliminating the risk of deformation and fracture.

Highly efficient and automated

Aluminum laser engraving is driven by computer software control, which can meet large-scale industrial production in a single operation.

Since the machine control allows for fully automated marking, it reduces labor costs and avoids manual errors. This not only ensures timely and fast delivery but also guarantees production efficiency and accuracy.

Economical and environmentally friendly

Laser engraving on aluminum is an eco-friendly, pollution-free processing technology. As long as the software design is set correctly during the engraving process, there will be no material waste.

The entire processing only requires a laser machine and aluminum material; it does not need to use inks, solvents, or other consumables, nor will it produce harmful chemical waste. Therefore, aluminum laser engraving is an economical and environmentally friendly option.