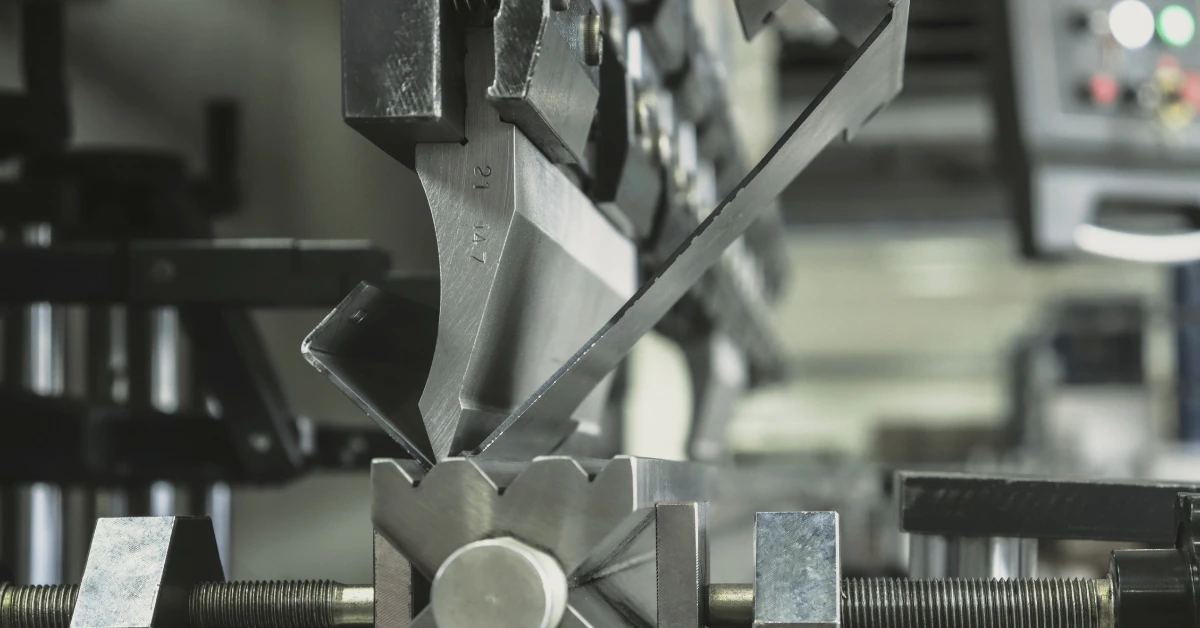

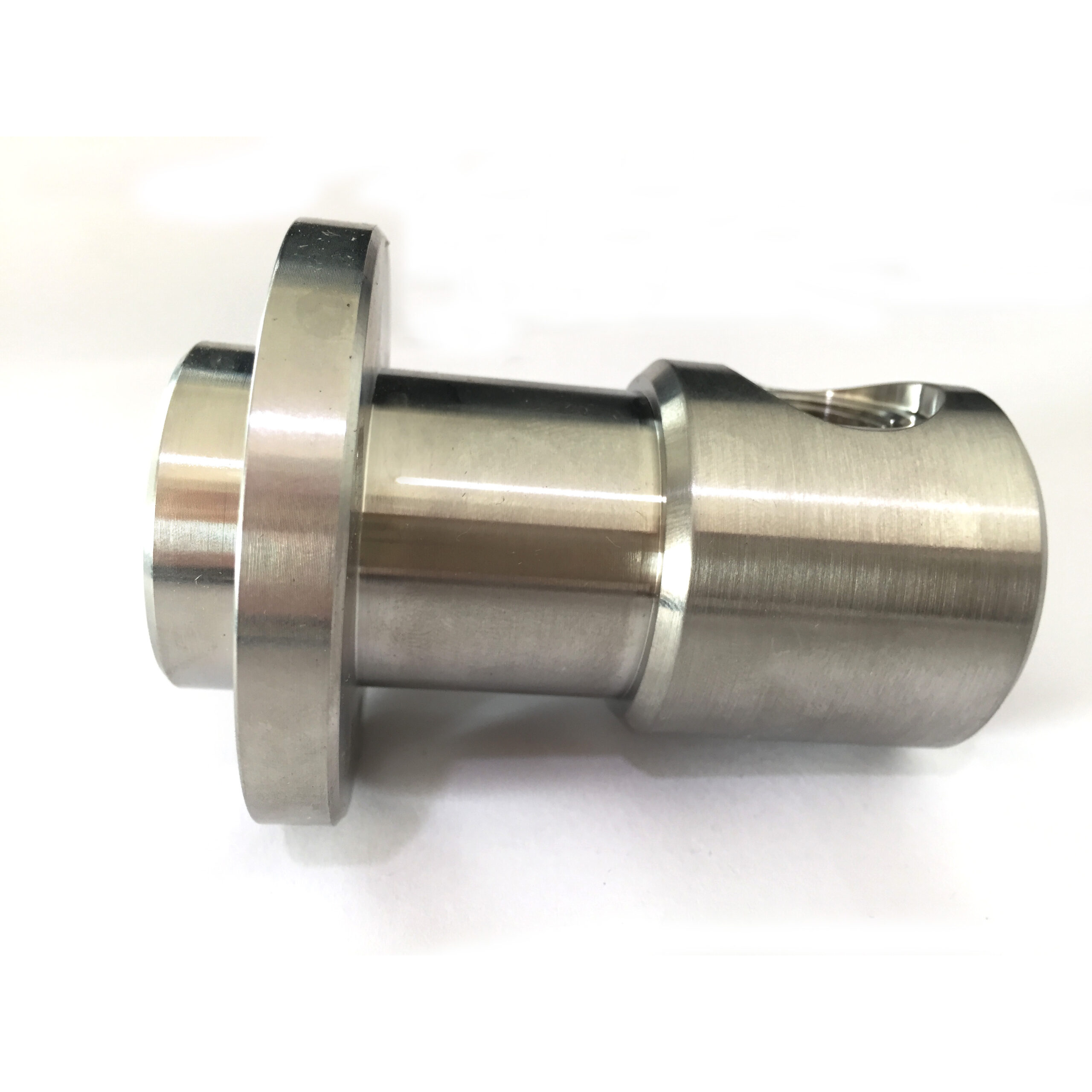

The metal stamping is accomplished by a wide range of sophisticated machines which give the best results of pressing metal sheets into the accurate components. Press machines, such as mechanical, hydraulic, and servo types, as well as custom-made dies and tooling, have a role in cutting, bending, and forming processes. The feeders and coil handling equipment facilitate material flow into the press, which are reduced by the lubrication systems, and part removal is facilitated. Inspection and quality control tools e.g. gauges, and vision systems, are used to maintain standards of production. The other critical factor is material handling and automation tools such as conveyors and robotic arms which create a smooth assembly line that is not only efficient but also safe. Together, these machines are the metal pressing equipment, and the whole setups are the source of the manufacturing of high-quality metal parts in a range of different industries.