Here’s a detailed explanation of salt spray testing for metal components:

Salt Spray Testing of Metal Components

Salt spray testing is a standardized, accelerated corrosion test method used primarily to evaluate the corrosion resistance of metallic components, especially those with protective coatings (e.g., paint, plating, galvanizing) or inherent corrosion resistance. It simulates a severe corrosive environment in a controlled laboratory setting.

Key Components of the Test:

Test Chamber: A sealed, temperature-controlled chamber specifically designed for salt spray testing.

Salt Solution Reservoir: Holds a prepared sodium chloride (NaCl) solution.

Atomizing Nozzle System: Compressed air passes through the salt solution, creating a fine, dense fog (aerosol) of salt-laden droplets.

Settling Tower/Baffles: Ensures the fog settles evenly onto the test specimens positioned inside the chamber.

Specimen Holders/Racks: Non-corrosive racks to position the metal components at specific angles (usually 15-30° from vertical) to maximize exposure and allow runoff.

Heating & Control System: Maintains a constant chamber temperature (typically 35°C ± 2°C / 95°F ± 3°F for Neutral Salt Spray).

Collection Funnel(s): Measures the settling rate of the salt fog (typically 1.0 to 2.0 ml of solution per 80cm² per hour).

The Salt Solution:

Primary Standard (Neutral Salt Spray – NSS): 5% ± 1% Sodium Chloride (NaCl) by weight in distilled or deionized water. pH adjusted to 6.5 – 7.2 at 35°C.

Variations (Accelerated Tests):

Acetic Acid Salt Spray (AASS): Neutral salt solution + glacial acetic acid to lower pH to ~3.1-3.3. More aggressive for certain coatings like anodized aluminum or decorative chromium plating.

Copper-Accelerated Acetic Acid Salt Spray (CASS): AASS solution + copper chloride (CuCl₂). Highly aggressive, often used for fast evaluation of decorative copper/nickel/chromium plating systems.

Procedure:

Preparation: Components are thoroughly cleaned to remove contaminants (oils, fingerprints, dirt) that could affect results. Critical surfaces may be protected if only specific areas are being evaluated. Any intentional scratches (scribes) through the coating down to the substrate are made if required by the test standard.

Placement: Components are mounted on racks inside the chamber at the specified angle(s), ensuring they do not touch each other or conductive materials, and fog can freely settle on them.

Test Execution: The chamber is sealed, temperature is stabilized, and the salt fog is continuously generated and circulated for the specified duration. Duration varies significantly depending on the material, coating, application, and standard (common ranges: 24h, 48h, 96h, 240h, 500h, 1000h+).

Inspection: At the end of the test period, components are carefully removed, gently rinsed with clean water to remove salt deposits, and dried. They are then visually inspected for signs of corrosion:

White Rust: Corrosion product of zinc (e.g., on galvanized steel or zinc plating).

Red Rust: Corrosion of the underlying ferrous (iron) base metal.

Blistering: Formation of bubbles under the coating.

Cracking/Peeling: Failure of the coating adhesion.

Scribe Creep: Corrosion spreading from an intentionally made scribe line through the coating.

Evaluation: Results are compared against acceptance criteria defined in the relevant specification or standard. Criteria often specify:

Maximum allowable time to first red rust appearance.

Maximum allowable creep from a scribe (e.g., ≤ 2mm).

Maximum allowable percentage of surface area affected by white rust, red rust, or blistering.

Visual rating systems (e.g., ASTM D610 for rust, ASTM D714 for blistering).

Purpose & Applications:

Quality Control: Verify that production batches meet specified corrosion resistance requirements.

Comparative Testing: Evaluate different materials, coatings, surface treatments, or manufacturing processes for their relative corrosion resistance.

Research & Development: Screen new materials or coating formulations.

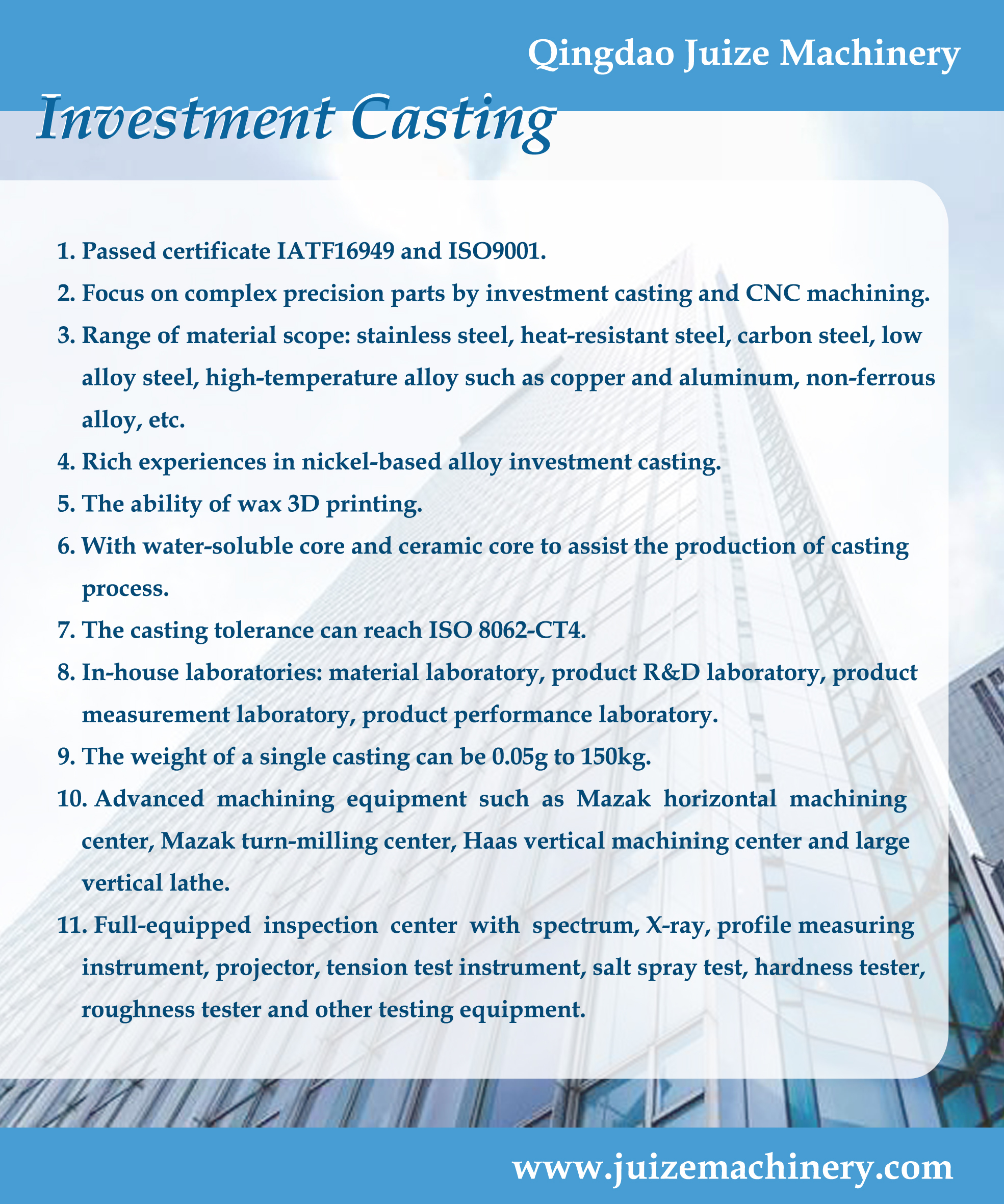

Specification Compliance: Demonstrate adherence to industry or customer specifications (e.g., automotive, aerospace, military, construction hardware).

Commonly Referenced Standards:

ASTM B117: “Standard Practice for Operating Salt Spray (Fog) Apparatus” (The foundational method, primarily describes NSS).

ISO 9227: “Corrosion tests in artificial atmospheres — Salt spray tests” (Covers NSS, AASS, CASS).

JIS Z 2371: “Methods of salt spray testing” (Japanese standard, similar scope to ISO 9227).

SAE J2334: “Cosmetic Corrosion Lab Test” (Used in automotive, often involves cyclic wet/dry conditions, sometimes incorporating a salt spray phase).

Many industry-specific standards (e.g., automotive OEM specs like GM 4298P, Ford BI 103-01, MIL-STD-810 for military, etc.) often reference or modify these core methods.

Limitations:

Accelerated but Not Predictive: Results correlate with real-world performance for similar exposure conditions but cannot precisely predict the actual service life of a component in all environments. It’s best for ranking materials/coatings.

Primarily Cosmetic: Focuses mainly on surface appearance and early-stage corrosion. Doesn’t assess structural degradation well.

Single Environment: Simulates primarily a marine/coastal atmosphere. Doesn’t account for factors like UV degradation, abrasion, temperature cycling, or pollutants found in industrial/urban atmospheres.

In summary, salt spray testing is a crucial, widely used accelerated laboratory method for assessing the corrosion resistance of metal components and their protective systems, providing a standardized benchmark for quality control and comparative evaluation, despite its limitations in predicting exact real-world service life. The specific test type (NSS, AASS, CASS), duration, and acceptance criteria are always defined by the relevant product specification or agreement between supplier and customer.