Gray Iron Applications

One of the key characteristics of gray iron is its ability to resist wear even when lubrication supply is limited (e.g., the upper cylinder walls in engine blocks). Gray iron is used to make engine blocks and cylinder heads, manifolds, gas burners, gear blanks, enclosures, and housings.

White Iron Applications

The chilling process used to make white iron results in a brittle material that is very resistant to wear and abrasions. For this reason, it is used to make mill linings, shot-blasting nozzles, railroad brake shoes, slurry pump housings, rolling mill rolls, and crushers. Ni-Hard Iron is specifically used for mixer paddles, augers and dies, liner plates for ball mills, coal chutes, and wire guides for drawing wires.

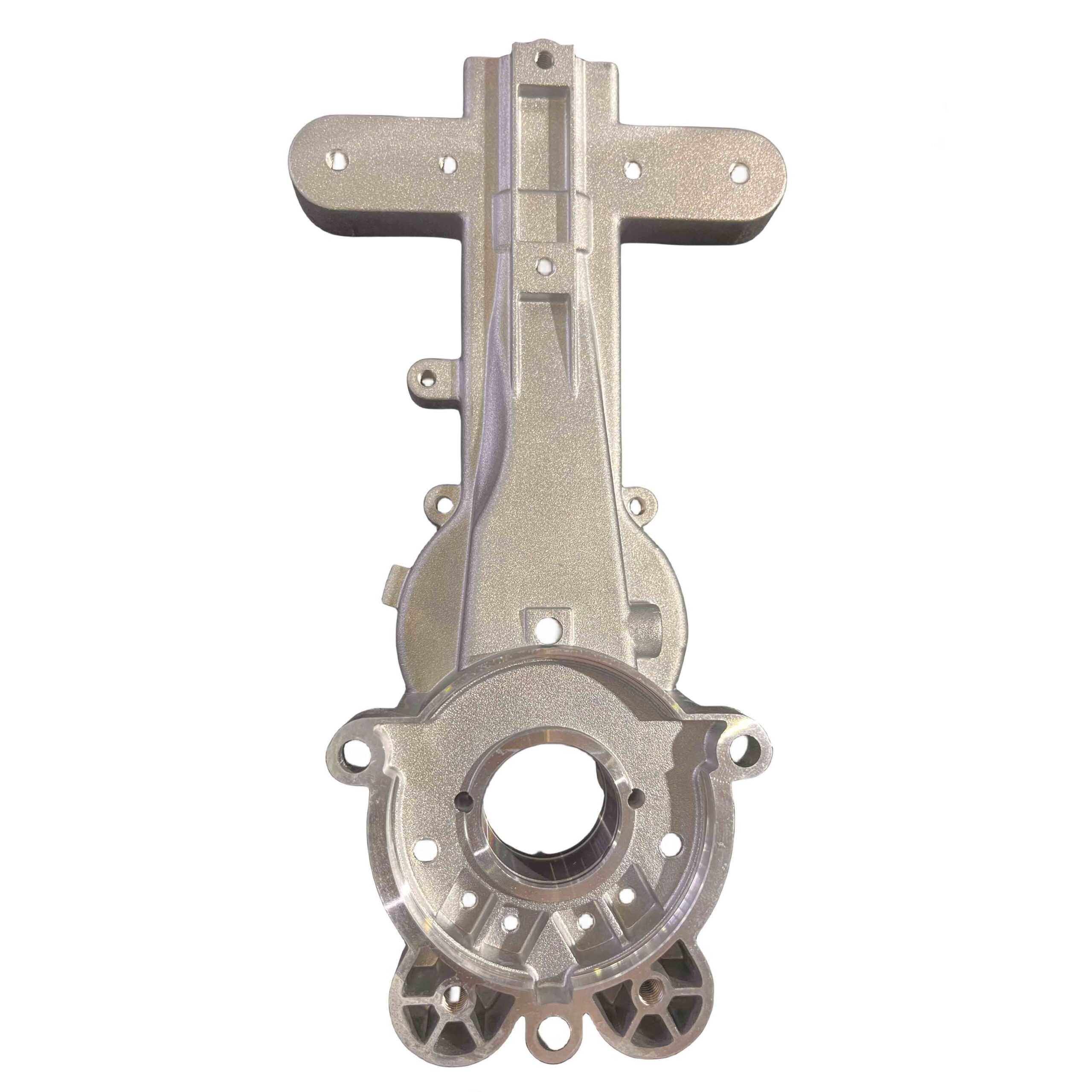

Ductile Iron Applications

Ductile iron itself can be broken down into different grades, each with its own property specifications and most suitable applications. It is easy to machine, has good fatigue and yield strength, while being wear-resistant. Its most well-known feature, however, is ductility. Ductile iron can be used to make steering knuckles, plowshares, crankshafts, heavy-duty gears, automotive and truck suspension components, hydraulic components, and automobile door hinges.

Malleable Iron Applications

Different grades of malleable iron correspond to different microcrystalline structures. Specific attributes that make malleable iron attractive are its ability to retain and store lubricants, the non-abrasive wear particles, and the porous surface which traps other abrasive debris. Malleable iron is used for heavy-duty bearing surfaces, chains, sprockets, connecting rods, drive train and axle components, railroad rolling stock, and farm and construction machinery.