True Centrifugal Casting

Symmetric hollow parts are the result of true centrifugal casting. Additionally, it revolves around a central axis. The mould spins rapidly. It typically falls between 300 and 3000 rpm. The inner surface has no core and is only shaped by centrifugal force. This technique effectively shares cylinders, bushings, pipes, and tubes.

Both horizontal and vertical axis orientations are compatible with the process. Long pipe production is suited for horizontal machines. At the same time, vertical machines are better at handling shorter parts. The amount of metal poured into the mould determines the thickness of the wall.

Consistent thickness along the length is guaranteed by uniform rotation. This process is used by industries to create bearing sleeves, gun barrels, and pressure vessels.

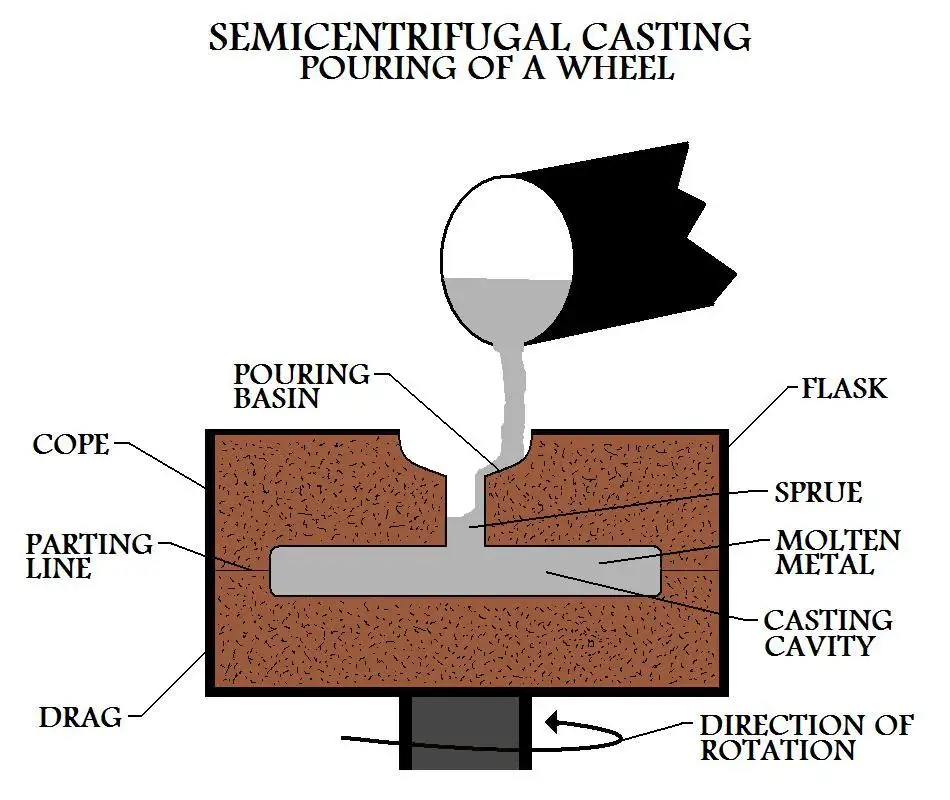

Semi-Centrifugal Casting

Semi centrifugal casting combines rotation with cores. The rotational axis passes through the part’s center of symmetry. However, the part has features beyond simple hollow cylinders.

Cores make internal passages. For instance, centrifugal force still improves metal feeding and reduces porosity. Similarly, rotation speeds remain lower than true centrifugal casting. It is 100 to 500 rpm. This technique produces wheels, pulleys, gears, and valve bodies.

Centrifuge Casting

A central sprue with numerous mould cavities spaced radially is used in centrifuge casting. The central axis is rotated by the entire assembly. Radial gates allow molten metal to flow from the sprue into individual moulds. During a single pour, a distinct component is produced in each cavity.

For small parts, this significantly boosts production efficiency. The moulds are fed by centrifugal force, which also minimises flaws. For rings, jewellery makers commonly use centrifuge casting. Additionally, dental labs use this technique to create crowns and bridges.