The pouring speed of steel castings shall be determined according to the specific conditions of castings. For thin-walled castings and castings with complex structures, rapid pouring should be adopted to avoid failure of pouring. When the mold has a large upper plane, it is also advisable to adopt rapid pouring to prevent the upper plane of the mold from peeling due to the long-term high-temperature radiation baking of the molten steel, resulting in sand inclusion defects in the steel castings.

When pouring small steel castings, pouring time is generally used to measure the speed of pouring. The pouring time of general small steel castings can refer to the following data:

Pouring time of general small steel castings

| Quality of steel casting/KG | Pouring time/s |

| <100 | <10 |

| 100~300 | <20 |

| 300~500 | <30 |

| 500~1000 | <60 |

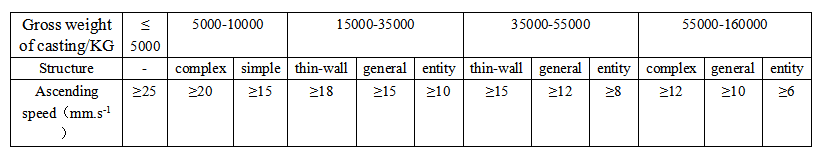

When pouring large and medium-sized steel castings, the pouring speed is expressed by the rising speed of liquid steel in the mold cavity. The proper rising speed can make the molten steel fill the mold cavity evenly, rapidly, and evenly to obtain high-quality steel castings. If the rising speed of molten steel is slow, the steel castings are prone to cold shut, pouring failure, sand inclusion, cracks, sand holes, and other defects; If the rising speed of molten steel is too fast, it is easy to produce defects such as choking, air hole, and slag inclusion. The rising speed of liquid steel for large and medium steel castings can refer to the following data:

The rising speed of liquid steel for large and medium steel castings

Although the pouring speed of steel castings is controlled by workers’ operation to a certain extent, it is directly affected by the diameter of the casting mouth. The velocity of molten steel flow at the opening of the steel forming barrel is proportional to the square root of the diameter of the opening and the height of the liquid steel level in the steel holding barrel and decreases gradually with the decrease of the liquid steel level. To obtain a proper pouring speed, the steel bucket must be equipped with a casting brick with an appropriate diameter, and when necessary, the steel bucket must be equipped with a double casting port.