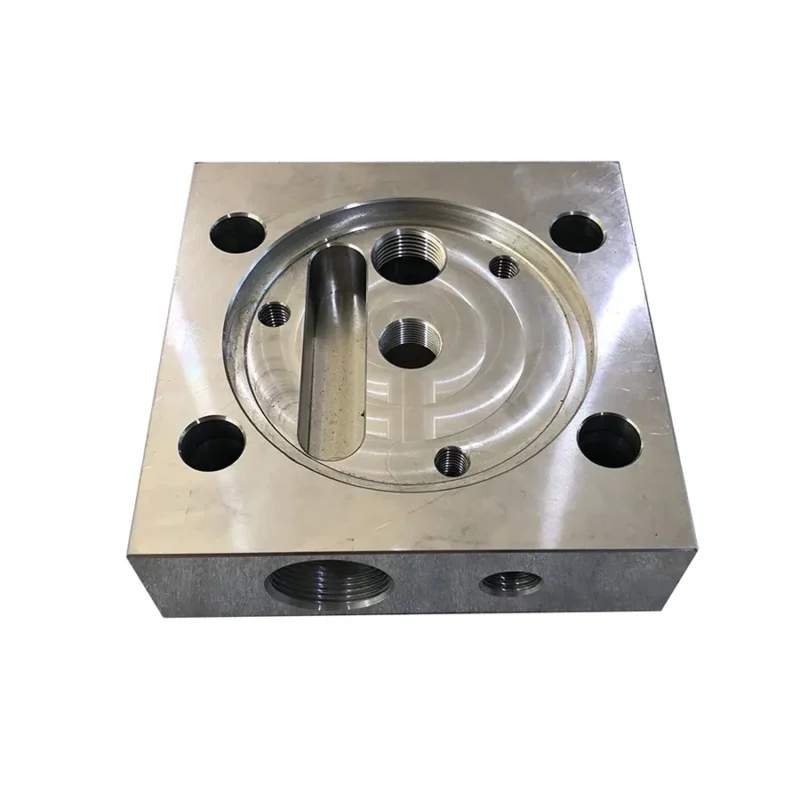

Description

| Service | OEM ODM |

| Material | Carbon steel, Stainless steel, Aluminum, Brass |

| Application | Industry Machinery, Automotive, Electricity |

| Machining Process | CNC Lathe, CNC milling center |

| Heat treatment | Hardening, Quench+ Temper |

| Surface treatment | Zinc plating, Powder coating, Painting, Anodizing |

| Quality Control | PFMEA, PPAP, APQP, Control Plan, MSA |

| Machining tolerance | ±0.005mm, ISO2768-mk |

| Testing facilities | Spectrometer, CMM, Callipers, micrometer, projector Load test machine, Hardness tester, rough meter |