Die casting employs a variety of metals, each chosen for its specific properties and suitability for different manufacturing requirements.

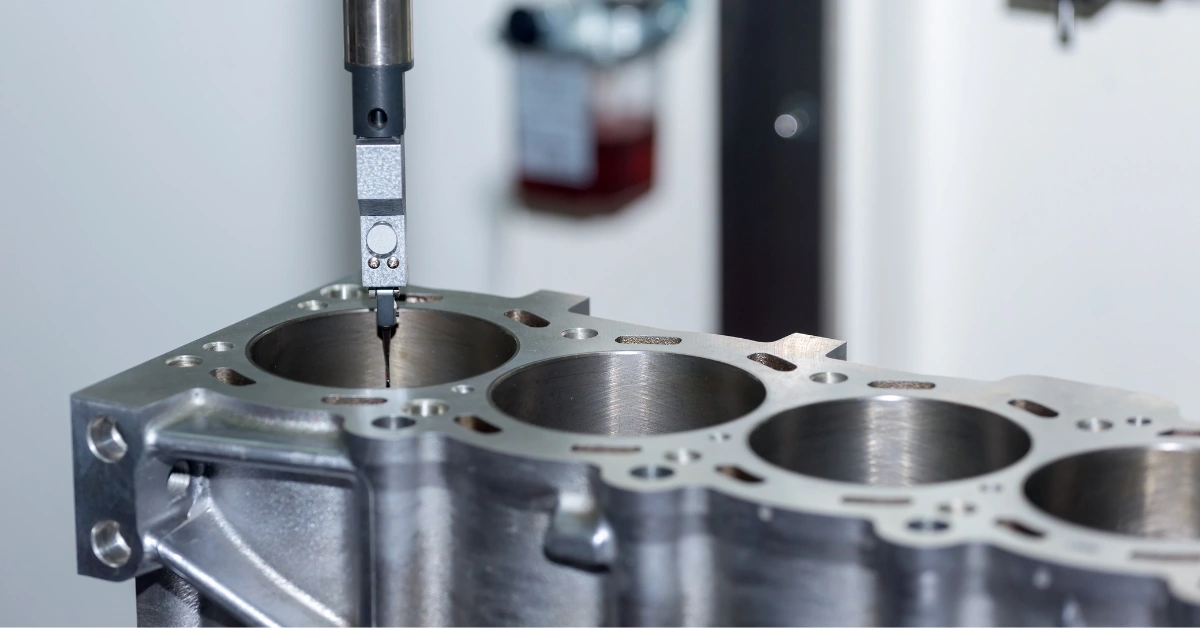

Aluminum and its alloy is one of the most popular materials in die casting. Its lightweight nature, coupled with excellent mechanical properties and corrosion resistance, makes it ideal for automotive, aerospace, and consumer electronics applications. Other commonly used materials include zinc, known for its low melting point and ease of casting, and magnesium, valued for being the lightest structural metal available, offering strength comparable to aluminum with lighter weight.die casting automotive engine component

The field of die casting is constantly evolving with the development of new materials and technologies. Recent innovations include the use of titanium and silicon in die casting, materials that provide unique properties like higher strength, lower weight, or better corrosion resistance. Researchers are also exploring semi-solid metal alloys which offer improved strength and reduced porosity compared to traditional liquid casting methods.

Each material used in die casting offers distinct advantages and challenges, influencing everything from production speed to final part performance. The choice of material is crucial and must align with the specific requirements of the intended application to ensure optimal performance and cost-effectiveness.