Most factories use special equipment and tools to control the heat treatment processes.

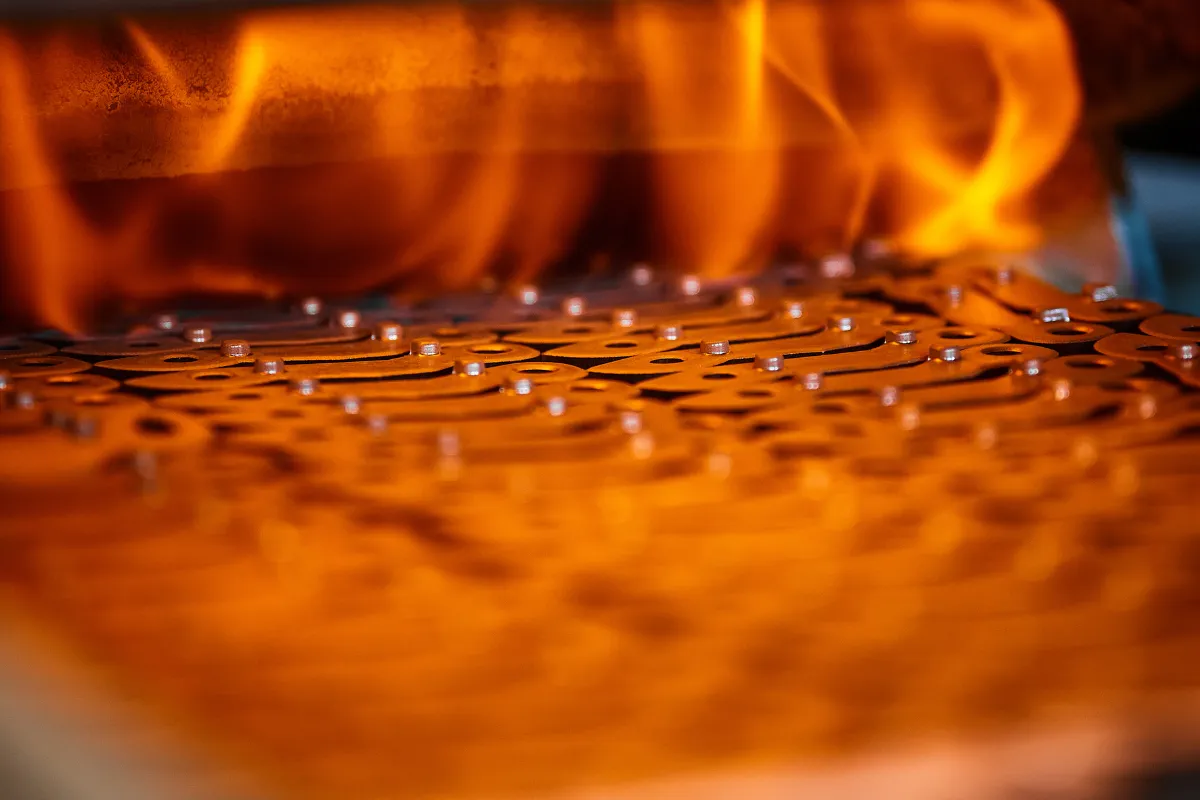

Furnaces

There are different kinds of furnaces used in the heat treatment process. Batch furnaces are used to treat one load at a time, and it is best used for small parts. Continuous furnaces keep the moving parts through a long heating tunnel and are best used for high-volume work.

On the other hand, vacuum furnaces keep the air out to prevent rust or any surface damage. They are mostly used for clean, high-precision work.

Induction & Laser Hardening

Induction hardening uses magnetic fields to heat the surface of the workpiece quickly. It works very well when making shafts or gear teeth. Laser hardening, however, does the same, but with a very hot and precise beam to heat a small spot.

Control Systems

These control systems are used to monitor the temperature and time closely. They help to ensure the metal gets the correct treatment needed for the work.