Material Grade:

Opt for the apt stainless steel classification contingent on sought-after attributes like resistance to corrosion and hardness.

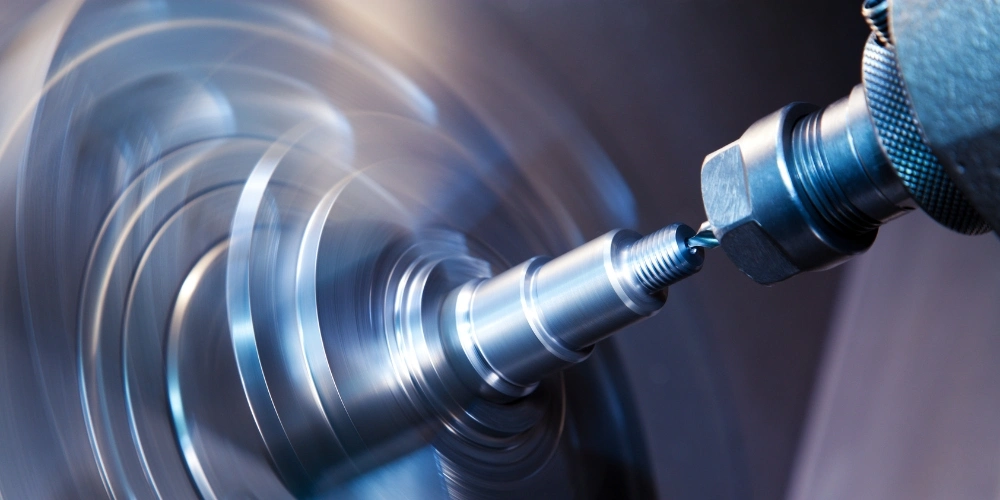

Design Complexity:

Scrutinize the intricacy of the component’s design to ascertain CNC machining’s efficacy in achieving the desired forms.

Precision and Tolerances:

Articulate with precision the requisite tolerances and exactitude levels for the meticulous manufacturing of the component.

Surface Finish Requirements:

Clearly outline the necessary surface finish, contemplating the spectrum achievable through CNC machining.

Batch Size:

Ascertain the volume of components required, striking a balance between cost-effectiveness for both diminutive and extensive production series.

Tooling and Fixturing:

Meticulously opt for cutting implements and fixturing methods for a streamlined and accurate machining process, factoring in tool compositions and coatings.

Cost Considerations:

Rigorously assess the overall customization costs, encompassing material expenses, machining duration, and any supplementary processes or embellishments.

Lead Time:

Delve into the temporal dynamics of production, integrating machining and any subsequent procedures into the overarching timeline.

Quality Assurance:

Enforce stringent quality control measures, entailing meticulous inspections and testing protocols, to uphold the specified benchmarks.