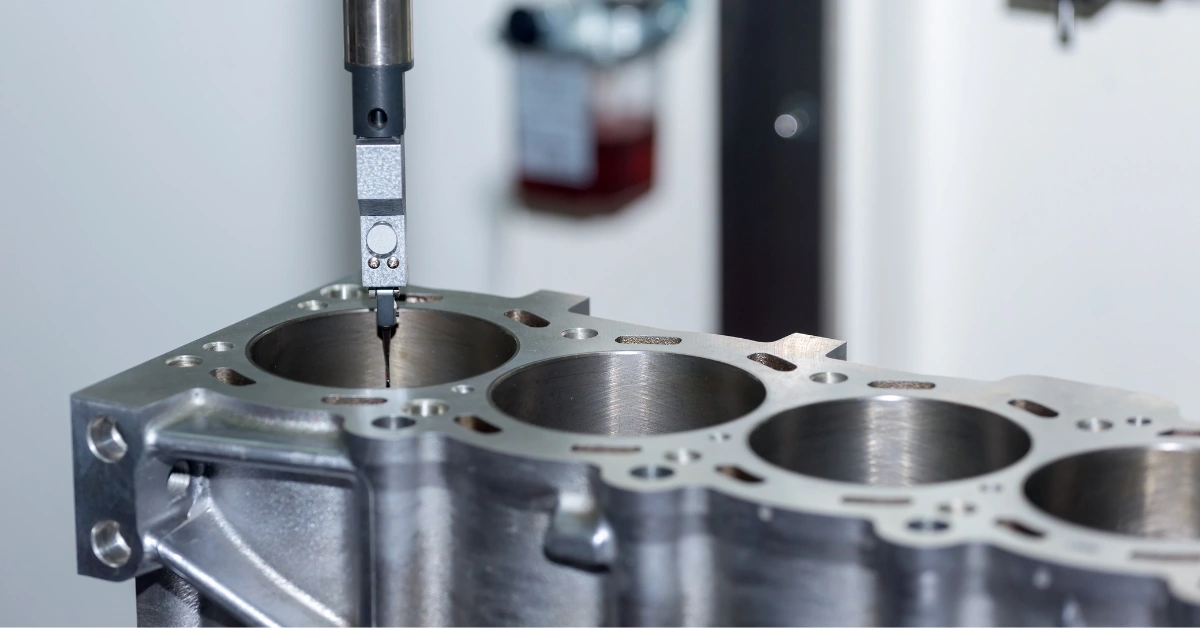

Die casting relies on selecting the right casting alloys and adhering to strict industry-specific standards to ensure high performance and durability of products. Aluminum alloy casting, popular for its strength-to-weight ratio, along with zinc and magnesium alloys, are chosen based on their specific properties like corrosion resistance and melting points. Quality assurance in casting services is critical, involving precise control over the die casting process and rigorous testing to meet the exacting standards of automotive, aerospace, and other industries. Techniques such as pressure die casting and vacuum die casting minimize defects, ensuring that components perform reliably under various operational stresses.