ZAMAK stands for Zinc, Aluminum, Magnesium, and Copper (Kupfer). It is a German metal alloy name. Zinc is the base material, ranging from 94% to 96%.

ZAMAK alloys offer benefits that make these alloys suitable for die-casting. In short, they provide low melting point, high fluidity, and strength-to-weight ratio. They also have other benefits that you will know in the later sections.

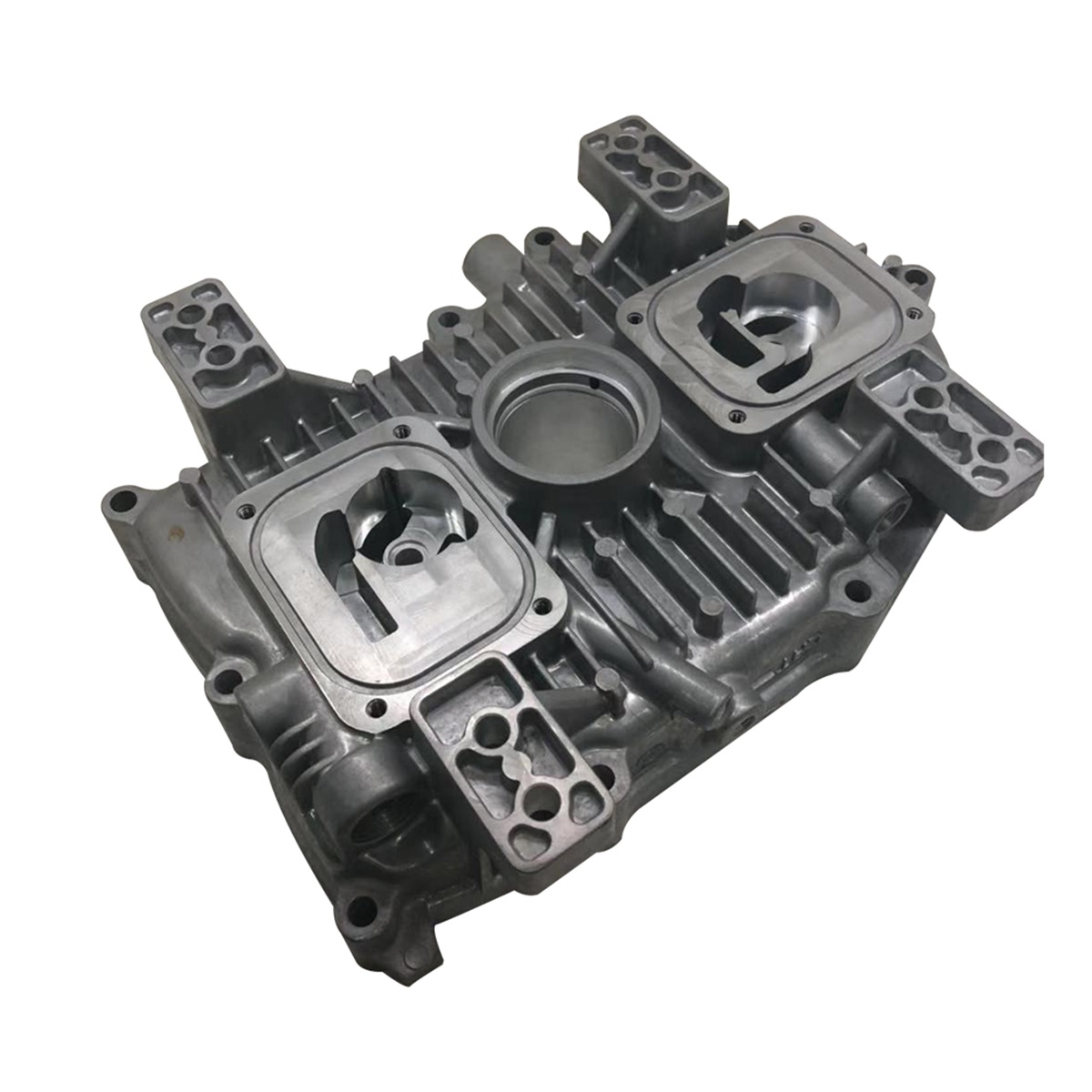

ZAMAK alloys are widely used in die-casting foundries. Die-cast ZAMAK alloy parts are prevalent in many applications. These casting parts are crucial, from car parts to electronics and hardware. They are also 100% recyclable.

Moreover, they usually come with a wide range of surface finishes. Since they offer good adhesion quality, you can do many surface treatments on ZAMAK parts. Because of this, ZAMAK alloy parts can offer a premium look. Besides, they are prevalent in decoration applications, too.