Die casting is a precision metal casting process that involves forcing molten metal under high pressure into a mold cavity. This method is distinguished by its speed and the superior quality of the finished products.

The origins of die casting trace back to the mid-19th century, initially used for printing type but swiftly adapted for creating intricate metal parts. Today, it’s integral to industries such as automotive, aerospace, and electronics, thanks to its efficiency and the ability to produce large volumes of complex shapes with fine details.

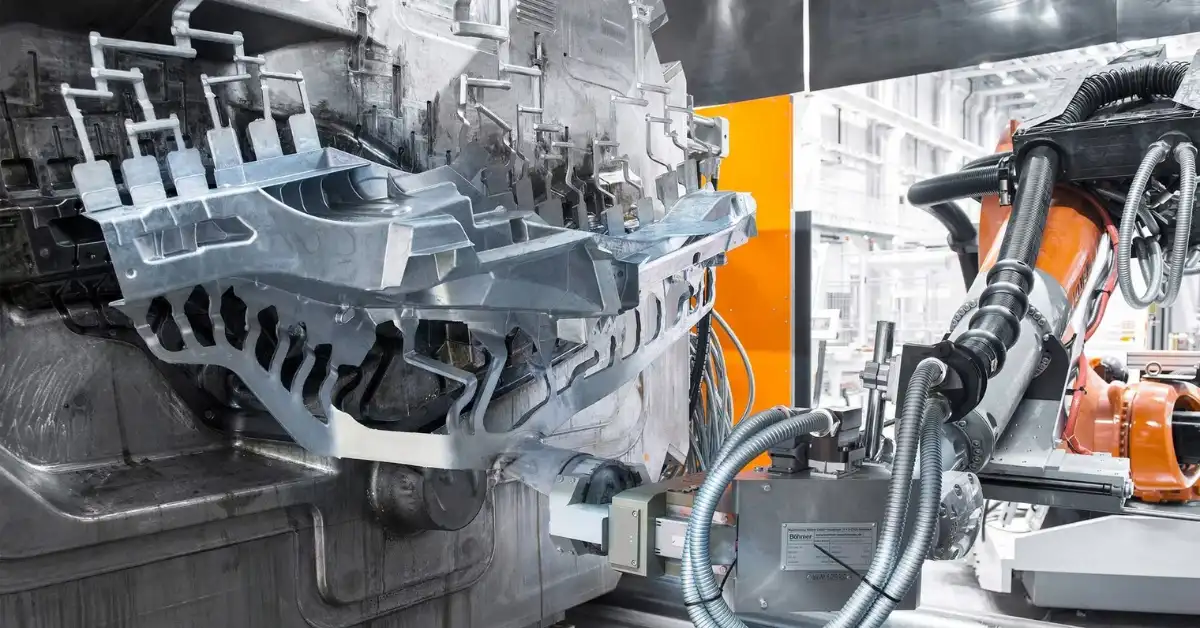

In comparison to other metal forming methods, die casting stands out for its exceptional ability to achieve tight tolerances and smoother surfaces without secondary machining. High pressure die casting and casting aluminum are particularly notable for their role in manufacturing durable and lightweight components, offering significant cost and material savings over techniques like forging and sand casting.

By leveraging aluminum die casting and other alloys, manufacturers can meet specific performance and strength criteria, making die casting a cornerstone in modern manufacturing.