HPDC or High Pressure Die Casting is usually known as a costly method of manufacturing as the tooling costs needed are the biggest factor. Let’s take a look at the factors which contribute to the cost of HPDC and then evaluate the amount required overall.

Initial Tooling Costs: This means that the tooling costs for HPDC can undoubtedly be high. The reason for this is that the manufacturing process requires inserts of the same nature, called dies, and machines that are able to work under high pressures and temperatures. This involves a substantial financial investment at the outset to create the molds and tooling that are required to execute these designs. While molds are required in this case, they can be reused multiple times if required for mass production which allows for the startup costs to be spread out over time.

Material Costs: The type of raw materials selected in many cases is the main cost driver in HPDC. Luckily, HPDC usually applies aluminum or zinc alloys, which are pretty inexpensive when compared to steel and titanium as the main materials. Moreover, thanks to the recyclability of aluminum and zinc alloys, one can save the costs in a viable and comparatively safe way for the environment.

Production Efficiency: In the discussion of HPDC benefits, one of its most notable aspects is high production efficiency. The technique is characterized by the speedy manufacture of large part quantities with little raw material waste. In spite of the high initial tooling costs, the high output and short cycle time of HPDC makes it possible for manufacturers to amortize their costs very soon after starting the production.

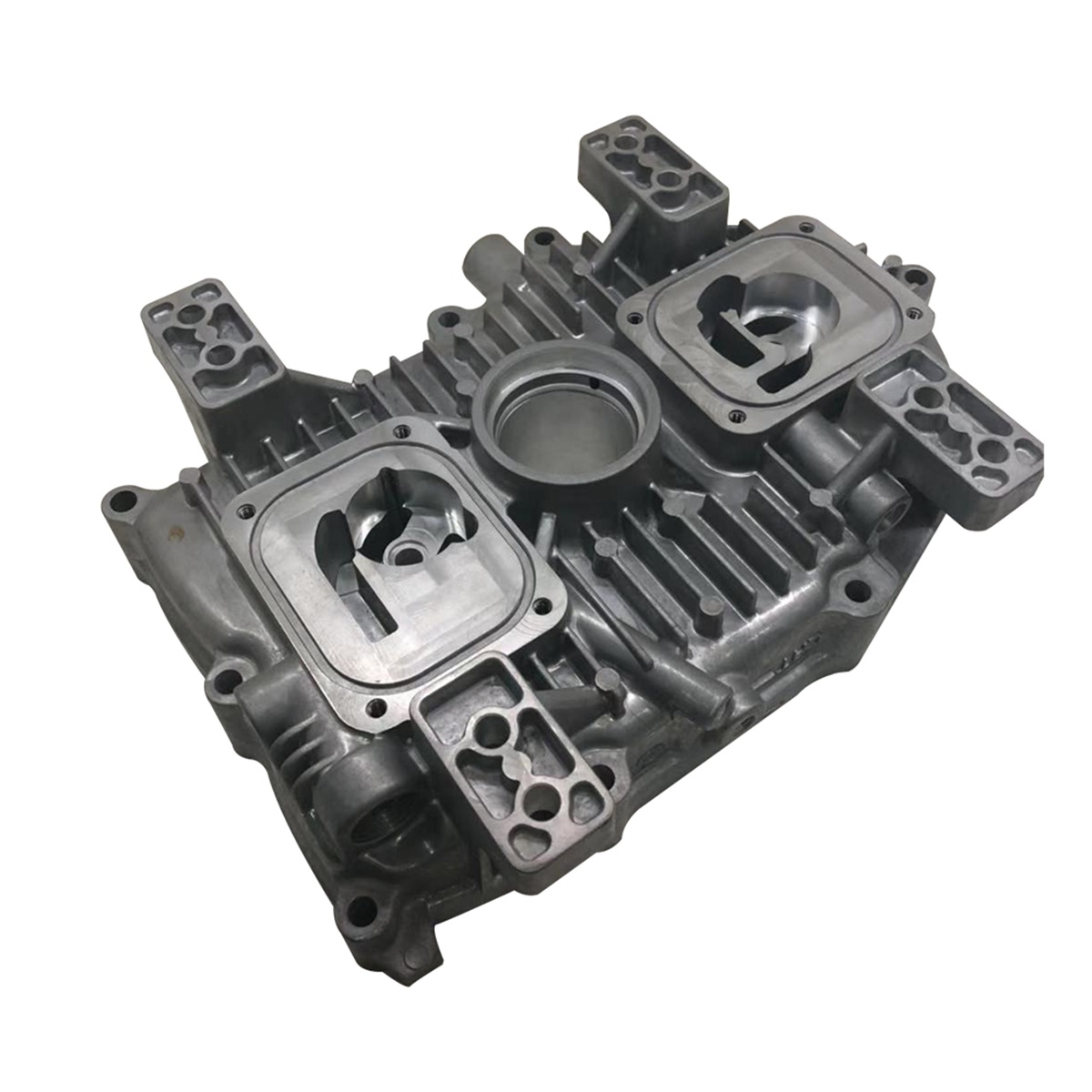

Quality and Precision: There are a lot of benefits in the precision and quality that is a result of HPDC and can lead to cost-saving in the end. The possibility of manufacturing final parts with very close tolerances, thereby reducing the work done by the process of post-processing and assembly, is one of the contribution of 3D printing technology to manufacturing. It does not only cut down on production costs but also develops accurate and reliable products.