When considering aluminum CNC machining, various factors influence the overall cost. Understanding these can help manage budgets and optimize production processes.

Factors Affecting Costs

- Raw Material Prices

- Machining Hours

- Labor Costs

- Tool Wear and Tear

- Product Complexity

Raw Material Prices

The cost of aluminum can vary based on market conditions. Specialized alloys or higher-purity aluminum might increase expenses.

Machining Hours

The complexity of the intricate appearances directly impacts the machining time. More intricate designs require more precision and time, driving up the cost.

Labor Costs

Skilled labor is essential for operating CNC machines and ensuring high-quality outputs. Higher labor costs can significantly influence the total expenses.

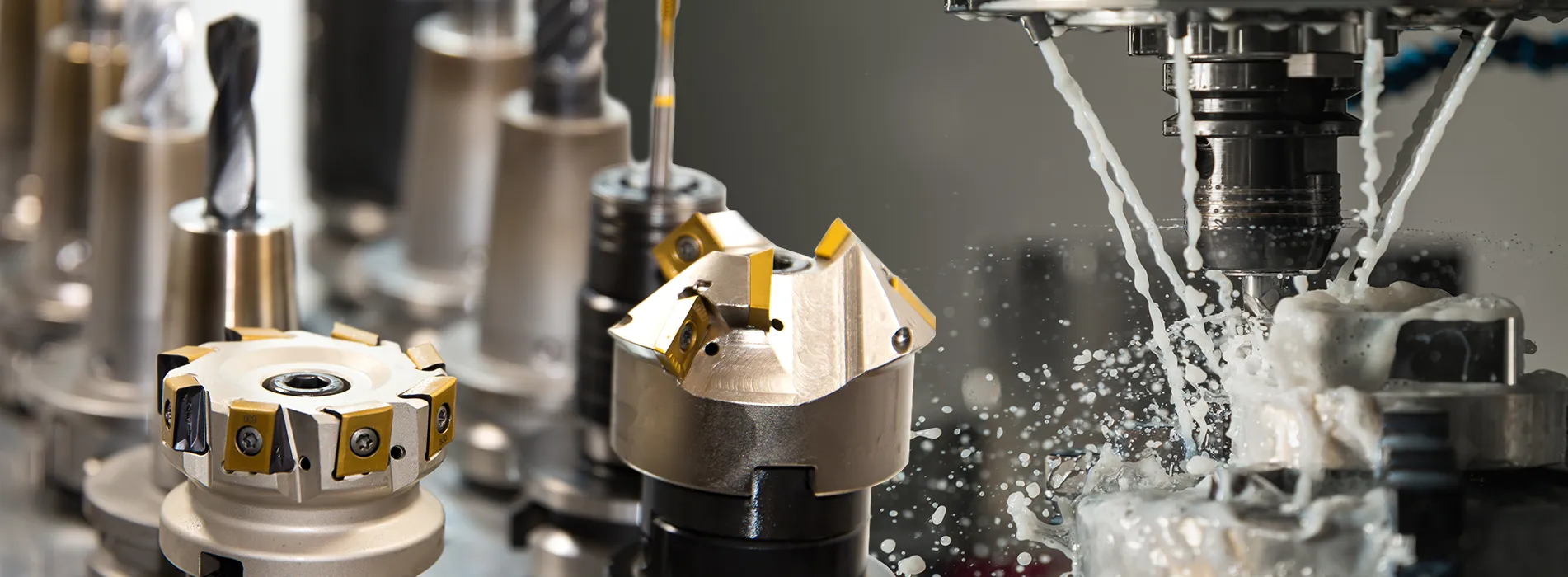

Tool Wear and Tear

Machining aluminum, particularly harder alloys, can wear down tools quickly. Frequent tool replacements and maintenance add to the overall cost.

Product Complexity

Complex parts with tight tolerances require more meticulous machining, increasing both time and labor costs.