There are many factors that affect the cost of CNC machining. Next, we will analyze the cost of CNC machining from several main aspects.

1. Equipment:

The cost of use, maintenance, and labor of advanced machine tools are higher. In general, the hourly machining cost of a 5-axis machine is 2-3 times that of a 3-axis machine. But this does not mean that the cost of choosing a 3-axis machine tool is the lowest, because the 5-axis machine tool is more efficient in machining complex parts, and the material loss rate is smaller, so the more complex the parts, the more cost-effective it is to choose 5-axis machining.

2. Materials:

The price of materials directly affects the price of the product. In addition, the difficulty of processing different materials is also a factor that must be considered. For example, the processing of titanium alloy requires the use of special tools, and the processing time is longer than that of aluminum alloy, and the cost is naturally higher.

3. Quantity:

Mass production will dilute the cost of pre-design and commissioning. At the same time, manufacturers can also continuously optimize the process and reduce unit costs in large-scale production.

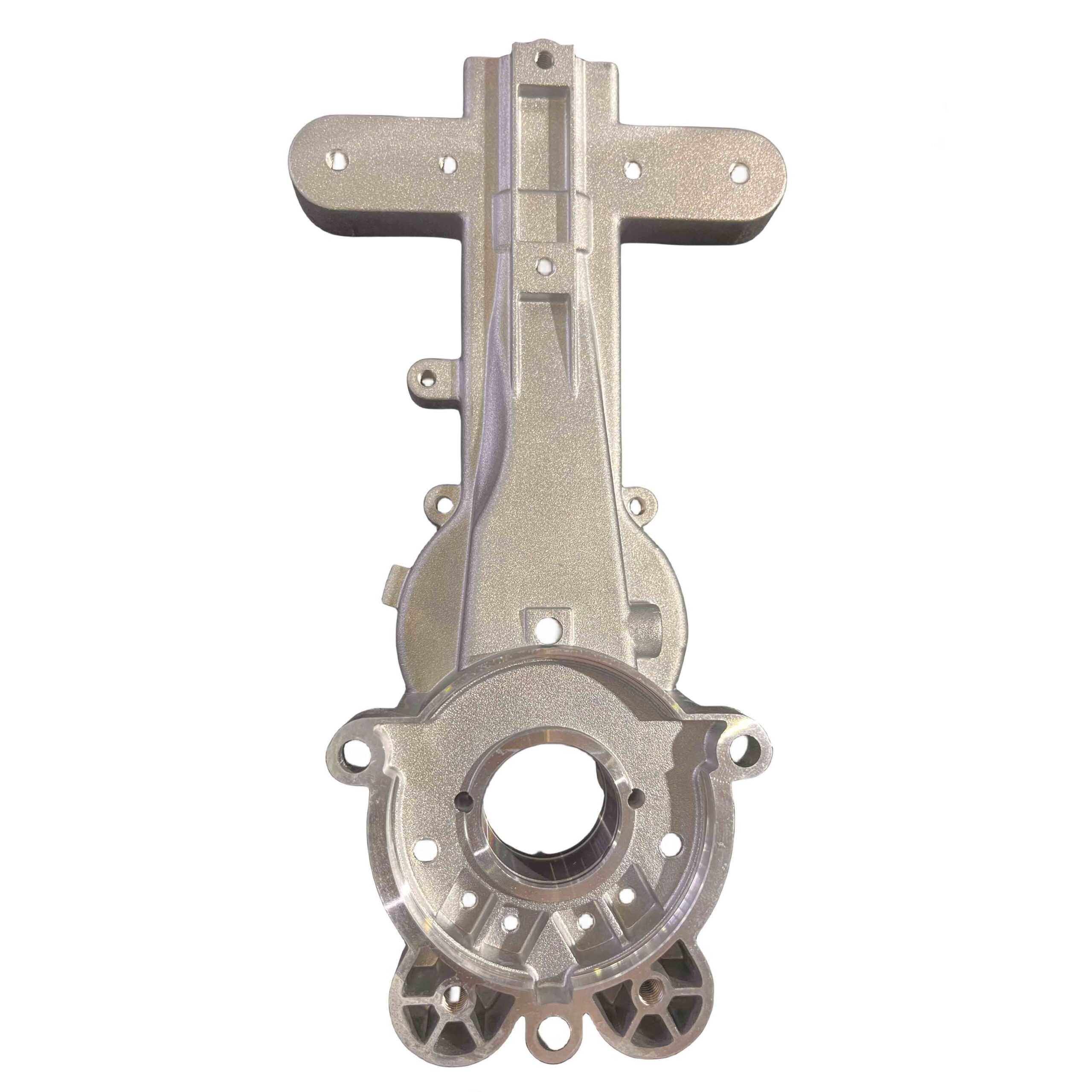

4. Part complexity:

Similar to complex and difficult-to-machine shapes such as curved surfaces, thin walls, deep cavities, etc., require more processes and time.

5. Machining accuracy:

Strict tolerance and surface roughness requirements directly increase the processing time and post-inspection cost. Moreover, the scrap rate will also be higher, which will lead to a sharp rise in costs.

In order to effectively reduce costs, we should follow the concept of Design for Manufacturing (DFM) in the design stage, and fully consider machinability. Pay attention to the functionality of the parts, relax the accuracy requirements of non-critical areas while meeting functional needs, and avoid over-design.