Limitations That CNC Milling Have on the Shapes of Plastic Products

CNC Milling, while highly versatile, does have limitations when it comes to the shapes of plastic products it can produce. Some of the limitations include: Undercuts: CNC Milling may have limitations in producing parts with complex undercuts, which require specialized tooling and can increase production costs. Intricate Internal Cavities: Extremely intricate internal cavities […]

Materials Commonly Used in Forging

1. Carbon Steels Carbon steels are the most widely used forging materials due to their excellent strength, ductility, and cost-effectiveness. They are classified by carbon content: Low-Carbon Steel (Mild Steel, <0.3% C): Excellent ductility and weldability; used for general-purpose components, automotive parts, and structural shapes. Medium-Carbon Steel (0.3% – 0.6% C): Balanced strength and toughness; commonly forged […]

Pros of Plastic CNC Milling Compared to Other Processing Methods

Compared to other plastic processing methods, the precision of CNC milling machines wins hands down for versatility and applicability in a wider variety of intricate designs. It has a high level of accuracy, the ability to customize elements and compatibility with many types of plastic materials, minimizing any material waste required for adjustment while also […]

Rack Plating vs. Barrel Plating

Both rack plating and barrel plating are foundational methods in electroplating. The core difference lies in how parts are held and moved during the plating process, leading to distinct advantages, limitations, and ideal applications. 1. Rack Plating In rack plating, parts are securely mounted onto custom-made fixtures or racks, which are then suspended in the plating […]

Applications of Plastic CNC Milling Parts

A variety of applications can be performed using plastic CNC milling parts, such as prototyping and electronic enclosures in addition to aerospace stuffs also medical devices. These plastic parts precision-machined find use in the areas of automotive, consumer products as well as packaging machinery industries thereby demonstrating their usefulness and accuracy. Given its ability to […]

Key Factors Affecting Tolerances in Sand Casting

The final tolerance on a casting part is influenced by many interconnected factors: Part Geometry: Complex shapes with thin walls, internal cavities, or large flat surfaces are more challenging to hold to tight tolerances. Pattern/Mold Quality: The precision and stability of the pattern and the sand mold itself are fundamental. Metal Characteristics: Different alloys have […]

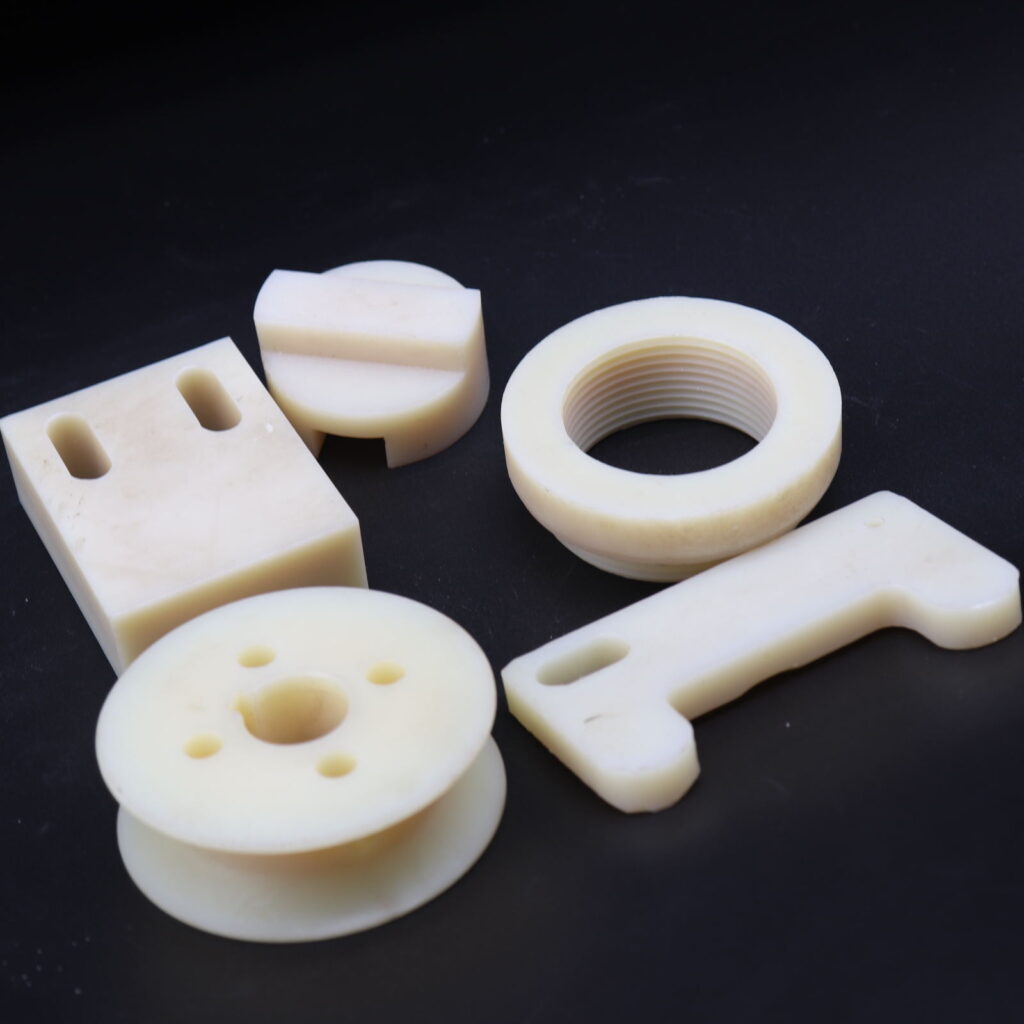

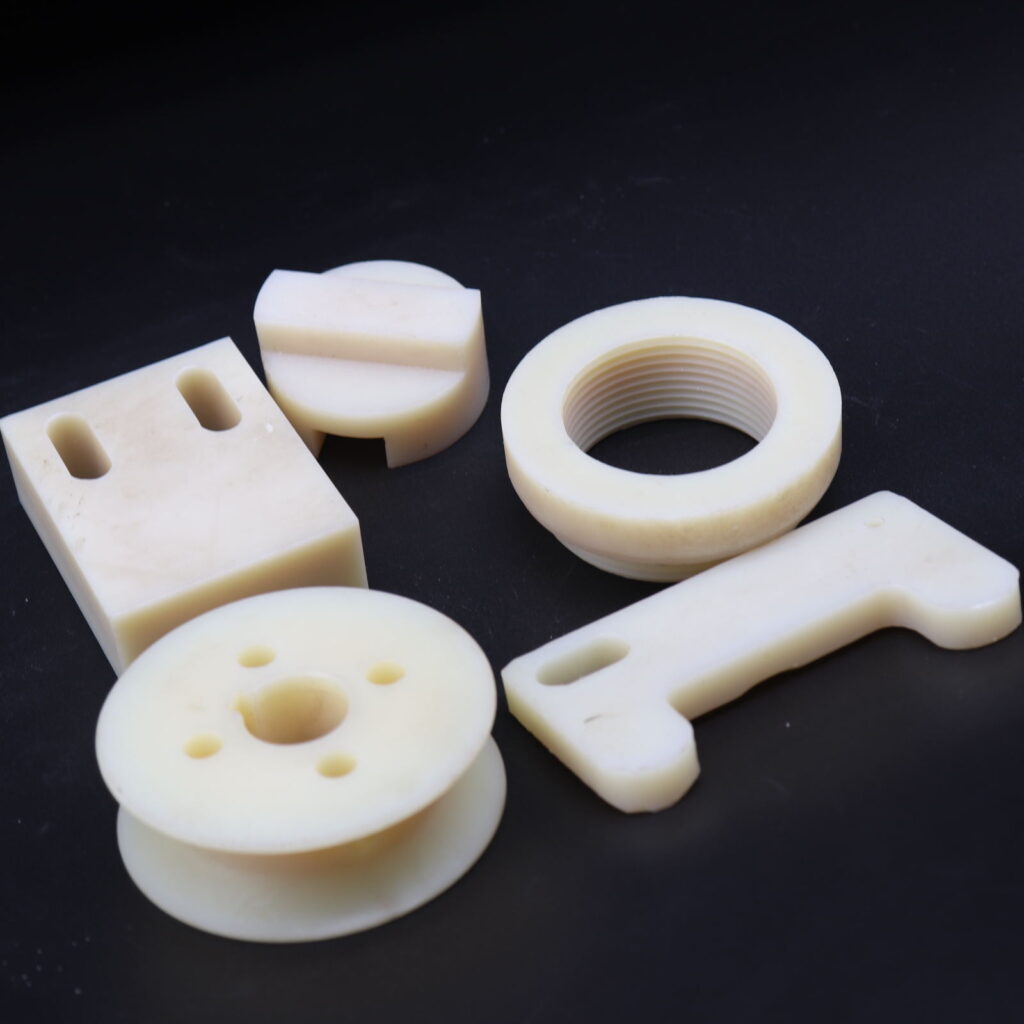

Types of Plastic Parts Suitable for CNC Milling

CNC milling is a very adaptable manufacturing technique that can be used for different plastic parts such as prototypes, cases of enclosures and gears, specific components which have unique shapes or functionality; medical devices in addition to those from the automotive and areospace sectors; consumer goods along with display panels plus packaging units. It leads […]

The Tolerance Range for Sand Casting

The tolerance range for sand casting is primarily governed by international and national standards, which define systematic grades rather than a single universal value. The achievable tolerance depends heavily on the chosen grade, the specific dimension of the cast part, and the casting process details. Here is a summary of the key international and national […]

Plastic CNC Milling

Plastic CNC milling, referred to as computer numerical control machining of plastic materials is a process whereby machines controlled by computers shape and cut plastic workpieces into the desired shapes sizes ,and dimensions. In plastic CNC milling, a cutting tool (usually an end mill or router bit) is computer-controlled to cut and produce the specified […]

Metals Suitable for Die Casting

Die casting is a high-pressure metal casting process characterized by forcing molten metal into a reusable steel mold (die) cavity. It is renowned for producing high-volume, dimensionally precise, and complex metal parts with excellent surface finish. The suitability of a metal for die casting hinges on several key properties: low melting point, good fluidity, minimal shrinkage, […]