Types of Medical Precision Machining Parts

Medical precision parts refer to a multitude of components critical for different medical devices. These components are carefully designed to the highest standards of quality and precision, fulfilling safety requirements for medical equipment. This includes, among other surgical instruments, implantable devices such as orthopedic and cardiovascular implants com They also include microfluidic devices, respiratory equipment […]

Materials for Powder Metallurgy (PM)

Powder Metallurgy is a manufacturing process that forms metal or ceramic components from fine powders. The material selection is vast and crucial, determining the final part’s properties, performance, and cost. PM materials can be broadly categorized as follows: Ferrous Metals (Iron & Steel-Based) This is the largest and most economically significant category, accounting for the […]

Injection Molding: A Versatile Manufacturing Powerhouse

Injection molding is a high-volume manufacturing process where molten material (most commonly thermoplastic polymers) is injected under high pressure into a precision-designed mold cavity. Once cooled and solidified, the part is ejected, resulting in a net-shape product that often requires little to no finishing. Its unique combination of efficiency, precision, and scalability makes it indispensable […]

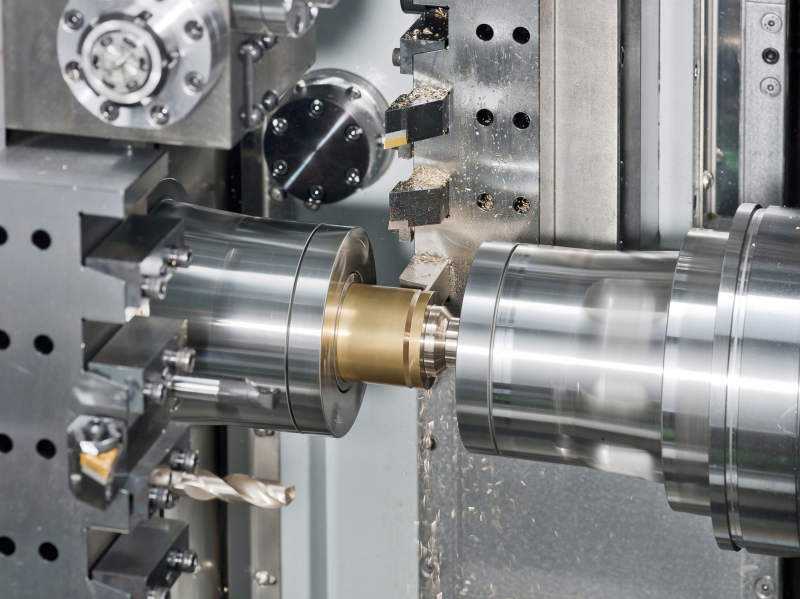

Turning

Turning is performed on a lathe, using the rotational motion of the workpiece and the linear or curvilinear motion of the tool to alter the raw material into a shape that meets the design specifications. It is suitable for machining rotational surfaces such as internal and external cylindrical surfaces, conical surfaces, end faces, grooves, threads, […]

Injection Molding Process

Injection molding is a high-precision, high-efficiency manufacturing process used to produce complex, dimensionally stable plastic parts in massive volumes. It is the dominant process for mass-producing identical thermoplastic and thermoset polymer components, ranging from tiny gears to entire automotive bumpers. Core Principle The fundamental principle is simple: Melt plastic, inject it into a mold under high […]

CNC Plasma Cutting

CNC plasma cutting is a subtractive process using plasma as the cutting material. The term “CNC,” refers to the machine being used. What this means is, the machine uses a plasma torch and moves in a direction controlled by the computer, allowing workers to focus just in setting it up. With CNC, no manual […]

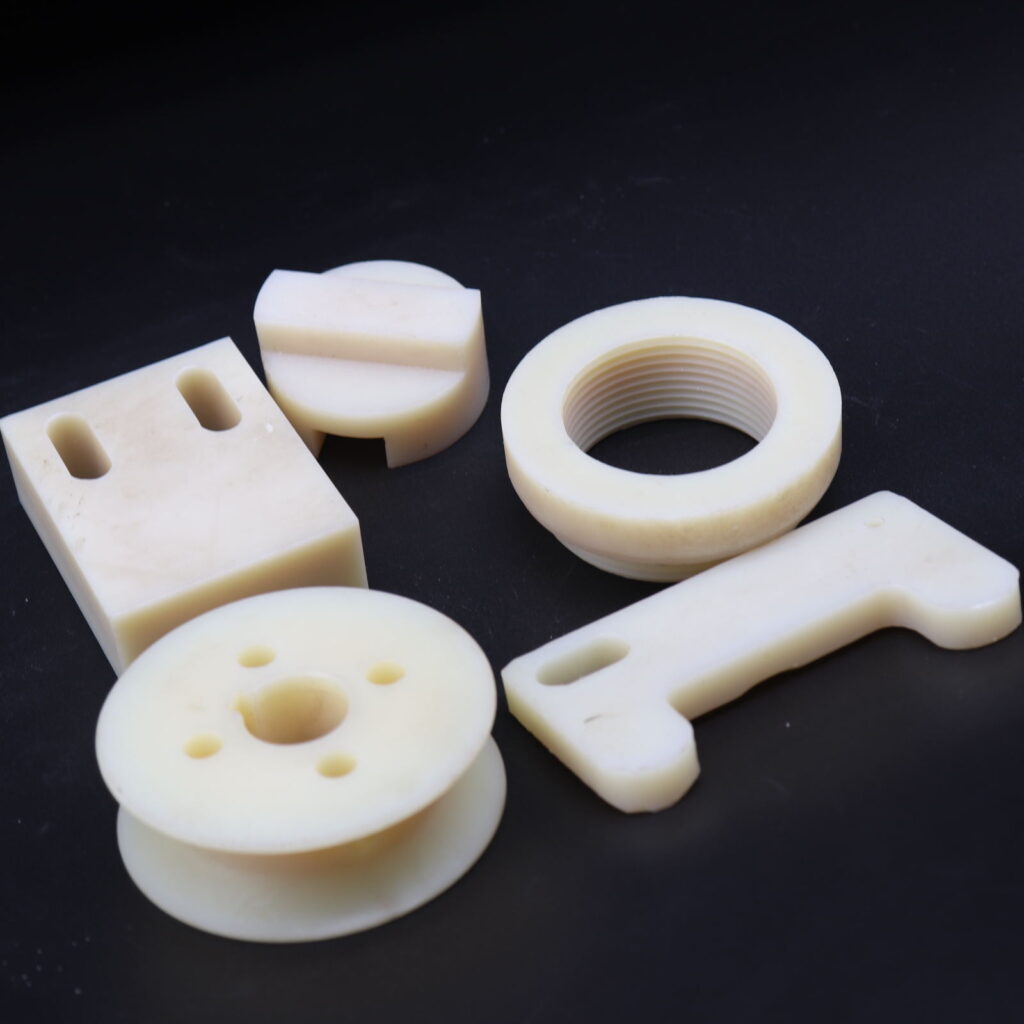

The Precision of Plastic CNC Milling Compare to Injection Molding

The precision of Plastic CNC Milling often surpasses that of injection molding. CNC Milling typically offers exceptional precision, often with tolerances in the range of 0.001 inches, making it suitable for producing highly accurate and intricate plastic parts. In contrast, while injection molding is efficient for high-volume production, its tolerances may be slightly lower due […]

How Stamping Dies Are Made

A stamping die is a precision tool used to cut, bend, and form sheet metal into desired shapes. Its manufacturing is a meticulous process combining design, high-precision machining, heat treatment, and assembly. Here’s a step-by-step breakdown. 1. Design & Engineering This is the most critical phase, determining the die’s success. Part Analysis: Engineers analyze the 3D […]

Forging: Applications and Impact

Forging is a fundamental manufacturing process that involves the shaping of metal using localized compressive forces, typically delivered by a hammer or die. It is renowned for producing parts with superior strength, structural integrity, and reliability compared to other methods like casting or machining from billet. Its applications span virtually every heavy-duty and critical-performance industry. […]

Forging: A Comprehensive Overview of Its Advantages

Forging is a foundational manufacturing process that involves the shaping of metal using localized compressive forces, typically delivered by a hammer or die. It is one of the oldest known metalworking techniques, yet it remains irreplaceable for critical, high-performance components. Its advantages stem from the fundamental alteration of the metal’s internal grain structure. 1. Superior […]