Methods for Detecting and Verifying the Magnetic Field in MT Equipment

Here are the primary methods for detecting and verifying the magnetic field in Magnetic Particle Testing (MT) equipment, as per industry standards (e.g., ASTM E1444/E1444M, ISO 9934): Tangential Field Strength Measurement (Direct Measurement): Tool: Tangential Field Probe (Teslameter/Gaussmeter) with a Hall-effect sensor. Method: Place the sensor probe perpendicularly (tangentially) on the part’s surface in the area of […]

How to Select Metal Fabrication Methods

Here’s a comprehensive guide to selecting metal fabrication methods, focusing on key decision factors: Key Factors Influencing Method Selection: Part Geometry & Complexity: Simple, Constant Cross-Sections: Extrusion, Roll Forming, Drawing (wire/tube). Hollow Parts: Casting (Die, Investment), Tube Hydroforming. Thin-Walled Parts: Stamping, Sheet Metal Forming (bending, deep drawing), Spinning. Complex Internal Features/Passages: Investment Casting, Additive Manufacturing (AM). Complex 3D Shapes: Casting […]

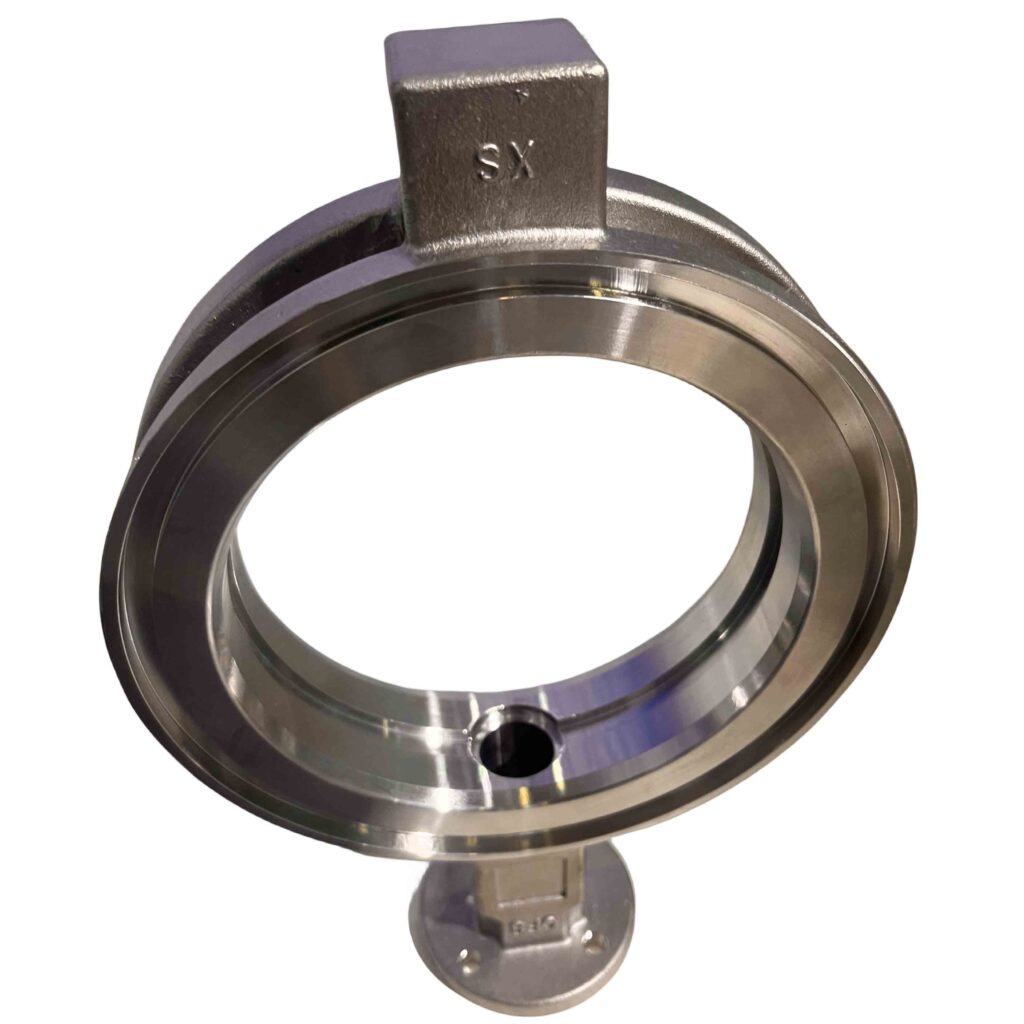

Typical Applications of Casting

Casting is usually used for intricate parts: Automotive: Parts such as engine blocks, cylinder heads, and brackets are often cast because they have complex shapes. Industrial Equipment: Casting can be used to make pump bodies, valve housings, and pipe fittings. Energy: Components in turbines, motors, and compressors are also made through the casting process. […]

Typical Applications of Forging

Forging can be used to make very strong parts in different industries: Automotive: Parts like crankshafts, connecting rods are usually made through the forging process. Aerospace: Forging can be used to make landing gears, engine mounts, and fasteners. These parts usually face high stress and need to be durable. Medical: Surgical tools and implant […]

Hot Rolling Process

Hot Rolling Process: A Comprehensive Overview Hot rolling is a fundamental metalworking process where metal stock (primarily steel, but also aluminum, copper, nickel, titanium, and alloys) is plastically deformed above its recrystallization temperature. This elevated temperature is critical as it allows the metal to be shaped with significantly lower forces and prevents work hardening, enabling large reductions and […]

Cold Drawing

Cold Drawing: A Precision Metal Forming Process Cold Drawing is a fundamental metalworking process used to reduce the cross-sectional area and increase the length of metal stock (wires, rods, tubes, bars) by pulling it through a converging die at room temperature or slightly elevated temperatures (significantly below the metal’s recrystallization point). It’s a type of cold working or strain hardening. Key Characteristics Temperature: Performed cold (ambient […]

Key Differences between Forging and Casting

Feature Forging Casting Grain Structure Forging keeps the grain aligned with the shape of the part, which improves its strength. This forms a new crystalline structure, which can lead to porosity and weaken the part from the inside. Strength & Durability Forged parts have better tensile strength, fatigue resistance, and impact toughness. Cast parts generally […]

Rubber Component Processing Methods

Here’s a comprehensive overview of rubber component processing methods: Rubber Component Processing Methods Rubber manufacturing transforms raw elastomers into functional components through distinct stages. Key processing methods include: 1. Mixing & Compounding: * Purpose: Homogenize raw rubber with additives (fillers, curatives, oils, antidegradants). * Primary Equipment: * Internal Mixers (e.g., Banbury Mixers): High-intensity, enclosed mixers for efficient large-scale compounding. * Open […]

What is Casting?

Process In the casting process, a metal is heated until it melts. The molten metal is then poured into a mold, which can be made of sand, metal, or ceramic. After that, the metal is allowed to cool down, and it takes the shape of the mold. When it is done cooling, the mold […]

Metal Surface Treatment Processes

Here’s a comprehensive overview of metal surface treatment processes, categorized by their primary function and mechanism: Purpose of Surface Treatment: Corrosion Protection: Forming barriers against environmental degradation. Wear & Abrasion Resistance: Increasing surface hardness and durability. Improved Aesthetics: Enhancing appearance (color, gloss, texture). Enhanced Adhesion: Preparing surfaces for painting, bonding, or coating. Altered Electrical Properties: Improving conductivity or providing […]