The Aluminum Alloy Series

The Aluminum Alloy Series (4-Digit System) 1xxx Series: Pure Aluminum (99.0% Minimum Aluminum) Major Alloying Element: None (Pure Aluminum). The last two digits indicate the purity above 99.00%. For example, 1060 is 99.60% aluminum. Characteristics: Excellent corrosion resistance. High electrical and thermal conductivity. Excellent workability (easy to form and weld). Low mechanical strength. Not heat-treatable; strength […]

Benefits of aluminum laser engraving

Permanent and durable Laser engraving creates marks by melting or vaporizing the designated area of aluminum, rather than simply printing on the material surface. Therefore, the engraved mark is durable and indelible. Even if the aluminum is subsequently subjected to surface treatment such as anodizing, the mark remains permanent and wear-resistant. High precision […]

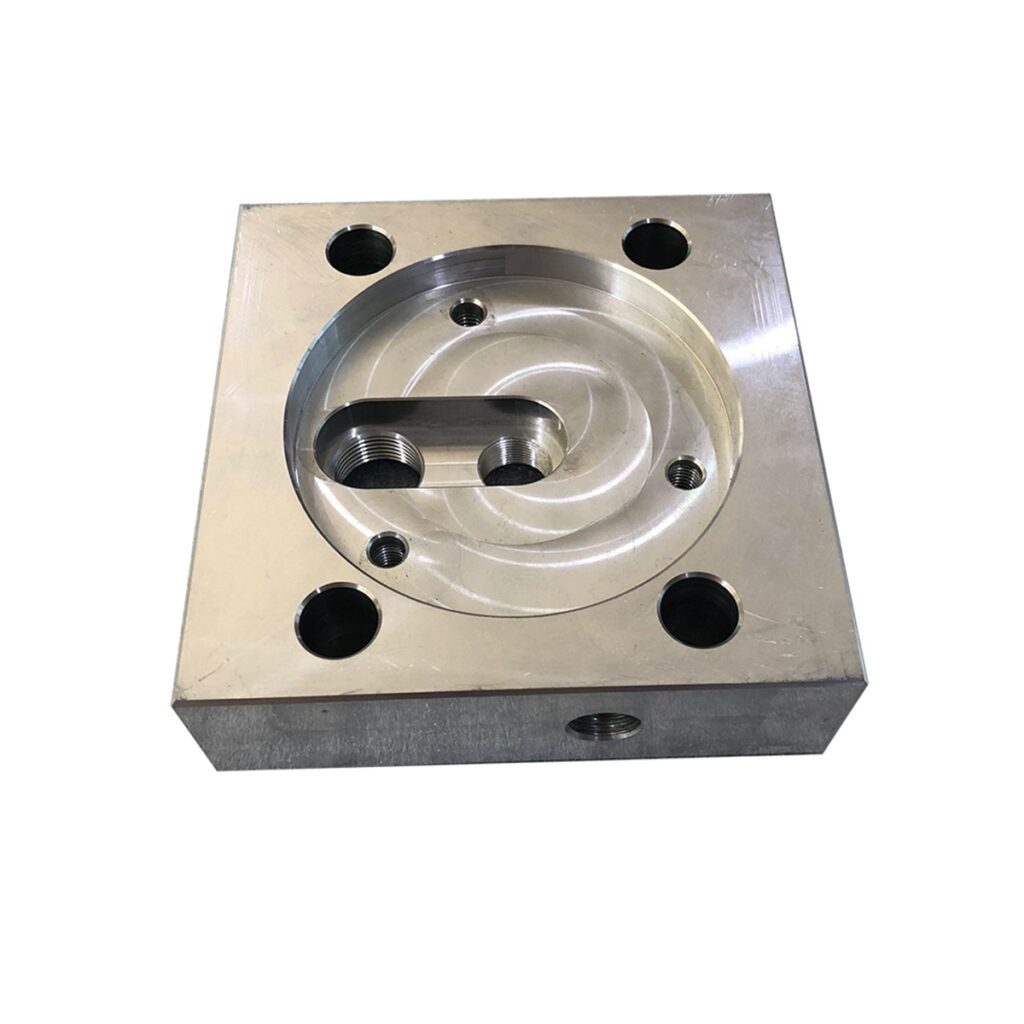

Components and Parts Aluminum is Commonly Used

Aluminum is one of the most versatile and widely used engineering materials due to its exceptional properties: it’s lightweight (about one-third the density of steel), corrosion-resistant (forms a protective oxide layer), highly malleable and ductile, a good conductor of heat and electricity, non-magnetic, and non-toxic. It’s also easily recyclable without loss of quality. These properties make it suitable for producing a vast array of components across […]

What is laser engraving?

As a subtractive surface treatment method, laser engraving forms patterns or text by making use of a laser beam to remove or alter the material’s surface. Advantages of engraving High precision Take the most used fiber laser engraving machine for example, it can engrave a thin line of 0.01mm(about 1/5 of human hair) at […]

Types of laser engraving machines for aluminum

According to the different media that generate lasers and the laser wavelengths, there are many types of aluminum laser engraving machines. Choosing the correct type of laser is crucial for the effect of aluminum engraving. Fiber laser Fiber laser has a wavelength of 1064nm, which can reach an absorption rate of about 4–10% by […]

Key Elements of a Process Flow Chart

A process flow chart (or flowchart) is a visual representation of the steps, sequences, and decisions involved in a process. Its core purpose is to communicate how a process works clearly and concisely to all stakeholders. The essential elements can be broken down into two main categories: Symbols (Shapes) and Connecting Elements & Best Practices. Core Symbols (The […]

Process Control in Hot Forging

Hot forging is a complex metal forming process where metal is shaped at high temperatures (typically above the recrystallization temperature). Precise control over every step of the流程 (process flow) is critical to achieving parts with the desired mechanical properties, dimensional accuracy, and microstructure, while minimizing defects and production costs. The control strategy can be broken […]

Aluminum surface finishing and laser engraving effects

The laser engraving effect on aluminum material does not depend on the type of substrate, but rather on its surface finishing condition. Here are three kinds of aluminum with different surface treatments that are commonly used for laser engraving: Anodized aluminum Based on the anodizing process, the thickness of the anodized layer typically ranges […]

The Performance Advantages of Brass Alloy

Brass, an alloy primarily composed of copper (Cu) and zinc (Zn), is one of the most versatile and widely used copper-based alloys. Its properties can be finely tuned by varying the proportions of copper and zinc and by adding other alloying elements like lead, tin, aluminum, or silicon. This results in a family of alloys […]

Normalizing vs. Annealing

In this section, you learn about the difference between normalizing and annealing. Cooling Differences: One major difference between annealing and normalizing is the rate of cooling. During normalizing, we cool the material in still air to produce a fine and tough grain structure. On the other hand, the workpiece is slowly cooled inside the […]