Key Properties of Forged Steel

High Strength and Toughness: It improves the metal’s ability to handle impact and stress without wearing out. Better Fatigue Resistance: Forged parts can withstand repeated use. It makes them ideal for parts like crankshafts and connecting rods. Uniform Grain Flow: Structural integrity and longevity increase due to grain alignment. Good Ductility and […]

The Types of Sand Casting

Sand Casting: An Overview Sand casting is a metal casting process characterized by using sand as the mold material. It is one of the oldest and most versatile metal forming methods, known for its ability to produce complex parts ranging from a few ounces to hundreds of tons. The process involves creating a mold from […]

Heat Treatment

The finished product can have some internal stresses or uneven properties. The solution lies in reheating. The product is reheated under controlled conditions.. After heating, the part is cooled at specific rates. Well, it gives the desired strength and toughness to the steel part. Common heat treatment processes include: Annealing: Annealing can soften the material, […]

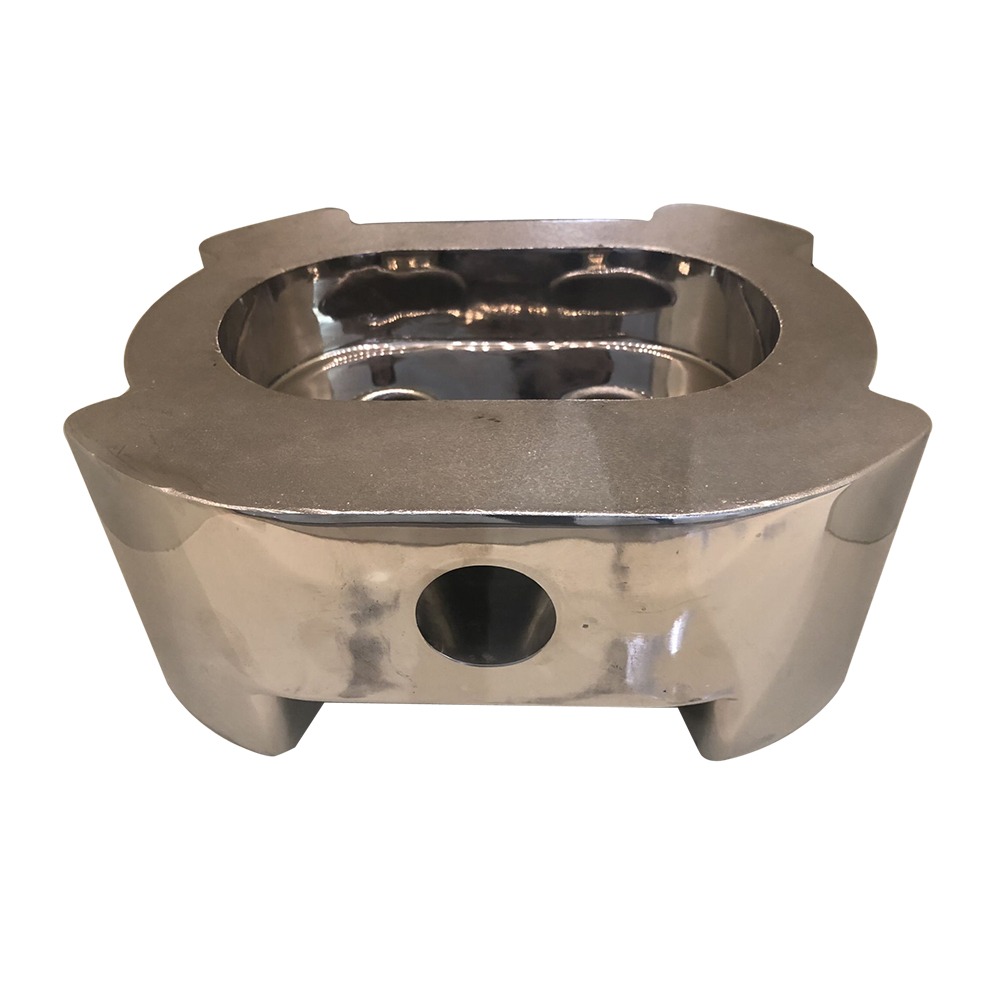

The Forging Process

Forging process may sound complex, but it becomes pretty easy and simple with the right guide. The main idea revolves around heading and shaping the metal with controlled force. Let’s break down the whole process into easy-to-understand steps. Step 1: Selecting the Right Material First, know what you want to create, then select the […]

Tensile Testing of Metallic Components

A tensile test, also known as a tension test, is a fundamental mechanical test used to determine the behavior of a material under an axial stretching load. It is one of the most widely used tests for metals, providing key data for engineering design, quality control, and material selection. The process can be broken down […]

Types of Steel Used in Forging

Steel is of different kinds, and each type has its own strength, flexibility, and use. As we are talking about forging steel, it is really important to select the right one, yes, because it directly affects the strength and durability of your final product. So, in this section, we will look at the most common […]

Forged Steel

“Forged steel is basically steel that is heated and pressurised into fine steel for boosting its strength and quality.” In simple words, the metal is heated to high Forged steel is steel that has been shaped and strengthened using heat and pressure. In simple words, a piece of metal is heated until it becomes […]

Metal Derusting Methods

Removing rust (iron oxide) from metal is a critical process for restoration, maintenance, and preparation for painting or coating. The chosen method depends on the type of metal, the extent of corrosion, the item’s size and shape, available tools, and safety considerations. These methods can be broadly categorized into Mechanical, Chemical, Electrolytic, and Thermal techniques. Mechanical Methods […]

How to Choose the Right Milling Type?

I’m going to discuss these factors so you may better choose what suits your needs. 1. Material Type: First of all, you should consider the properties of your workpiece material, like its hardness, toughness, or thermal conductivity. This is because all such properties actually influence a lot how easily would material can be machined. For […]

The Plastic-Coated Steel (PCS) Process

The Plastic-Coated Steel (PCS) process is a sophisticated manufacturing technique that involves bonding a layer of polymer (plastic) onto a steel substrate. This fusion creates a composite material that combines the superior mechanical strength of steel with the enhanced aesthetic, corrosion resistance, and functional properties of the polymer coating. This process is distinct from simple […]