Types of Medical Precision Machining Parts

Medical precision parts refer to a multitude of components critical for different medical devices. These components are carefully designed to the highest standards of quality

Medical precision parts refer to a multitude of components critical for different medical devices. These components are carefully designed to the highest standards of quality

Powder Metallurgy is a manufacturing process that forms metal or ceramic components from fine powders. The material selection is vast and crucial, determining the final

Injection molding is a high-volume manufacturing process where molten material (most commonly thermoplastic polymers) is injected under high pressure into a precision-designed mold cavity. Once

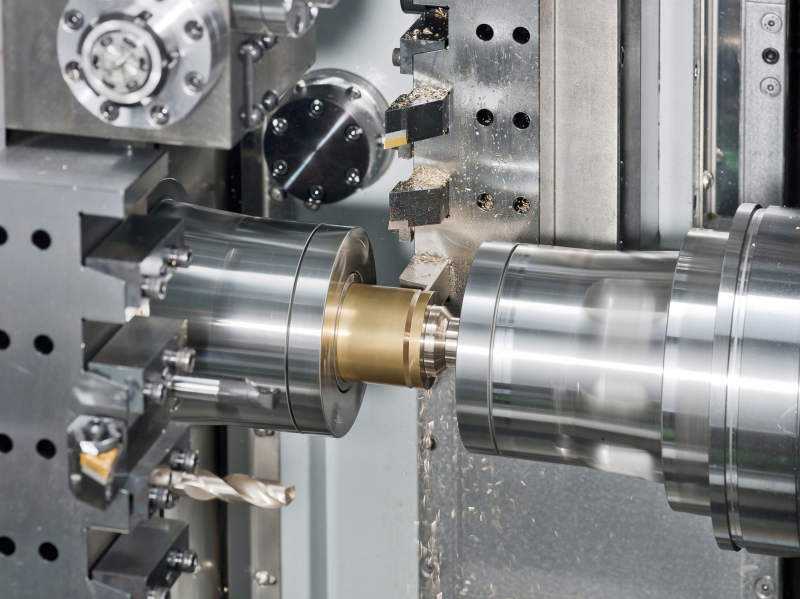

Turning is performed on a lathe, using the rotational motion of the workpiece and the linear or curvilinear motion of the tool to alter the

Injection molding is a high-precision, high-efficiency manufacturing process used to produce complex, dimensionally stable plastic parts in massive volumes. It is the dominant process for

CNC plasma cutting is a subtractive process using plasma as the cutting material. The term “CNC,” refers to the machine being used. What this means

The precision of Plastic CNC Milling often surpasses that of injection molding. CNC Milling typically offers exceptional precision, often with tolerances in the range of

A stamping die is a precision tool used to cut, bend, and form sheet metal into desired shapes. Its manufacturing is a meticulous process combining

Forging is a fundamental manufacturing process that involves the shaping of metal using localized compressive forces, typically delivered by a hammer or die. It is

Forging is a foundational manufacturing process that involves the shaping of metal using localized compressive forces, typically delivered by a hammer or die. It is

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.