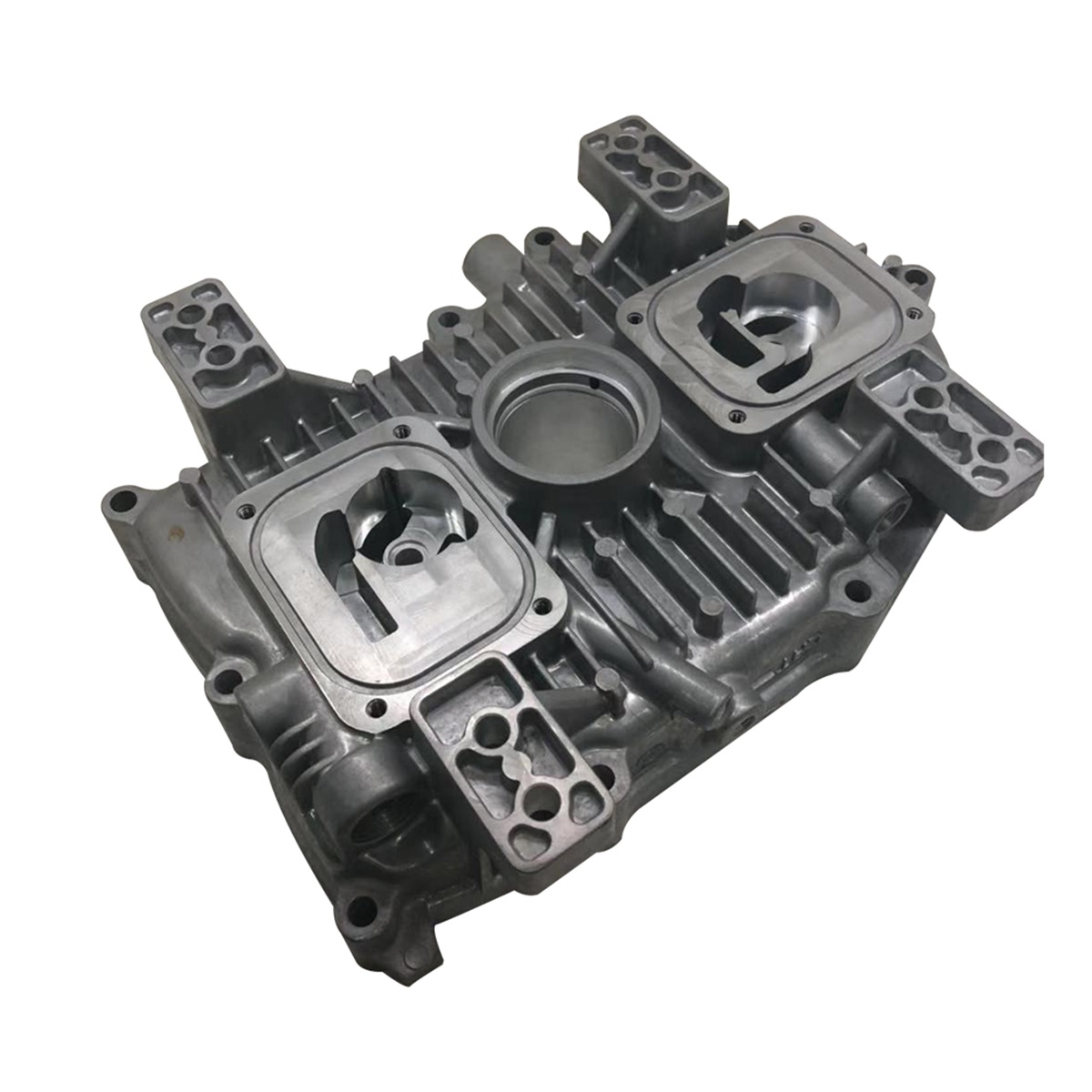

Examples of Cast Products

Engine Blocks and Cylinder Heads: Engine blocks and cylinder heads are often cast because of their complex internal structures and the need for precise cooling channels.

Engine Blocks and Cylinder Heads: Engine blocks and cylinder heads are often cast because of their complex internal structures and the need for precise cooling channels.

Casting excels in producing parts with complex shapes and large sizes, such as: Complex Shapes and Intricate Designs:Casting is perfect for components with complex geometries

Gravity die casting is a manufacturing process you can specify to produce high-quality metal parts with complex shapes and a relatively good surface finish. It’s

• Engine Parts: Engine parts like connecting rods, crankshafts, and camshafts are often forged because they must withstand high loads and stresses. The forging process

Tooling Cost While the per piece cost of die cast parts is relatively low, the tooling dies and maintenance costs can require a high

Forging is ideal for components that require high strength and durability, such as: Automotive and Aerospace Components: Forged parts are crucial in these industries due to

Complex Geometry Die casting can reliably produce custom die cast parts with thin walls and challenging geometry that is durable and dimensionally stable. Strength

Material Properties:Forged parts typically have superior strength, toughness, and fatigue resistance compared to cast parts due to the refined grain structure and work hardening. Production

The versatility and high production potential of die casting enable it for various applications and industries. Die casting products that are small to medium in

Casting is a manufacturing process where liquid metal is poured into a mold and allowed to solidify into a specific shape. Casting has a rich

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.