Car Parts Manufacturing Services

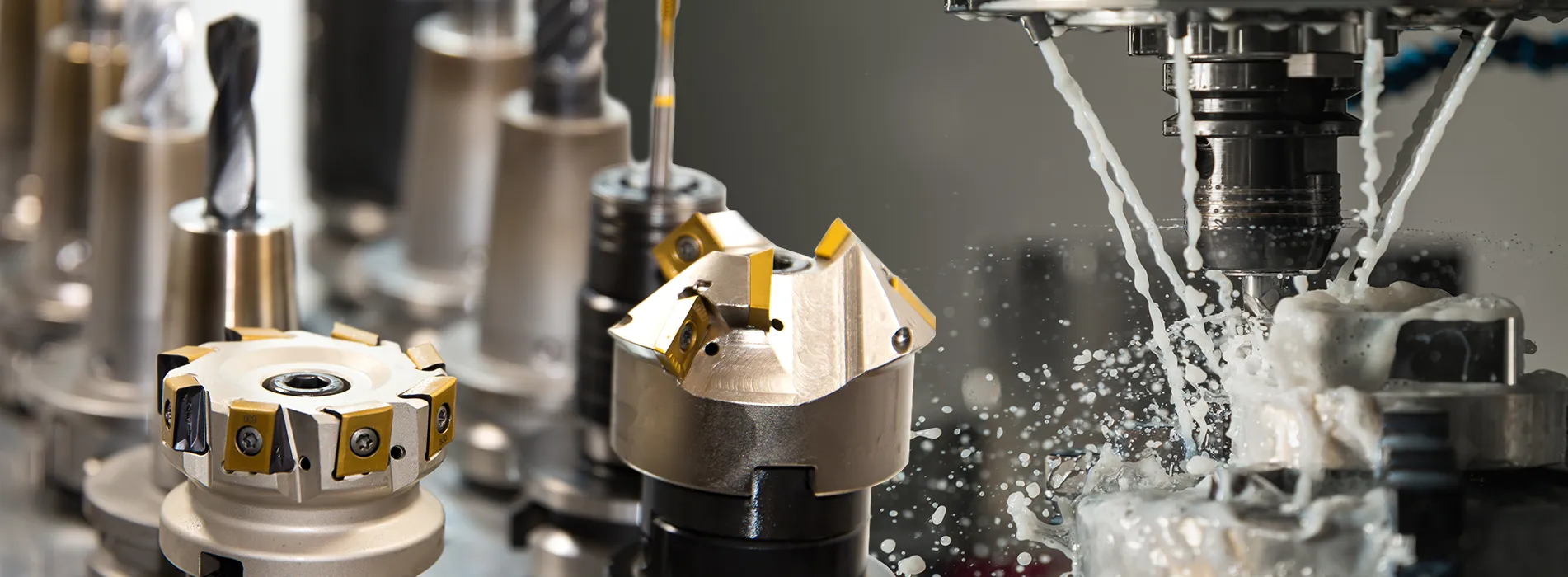

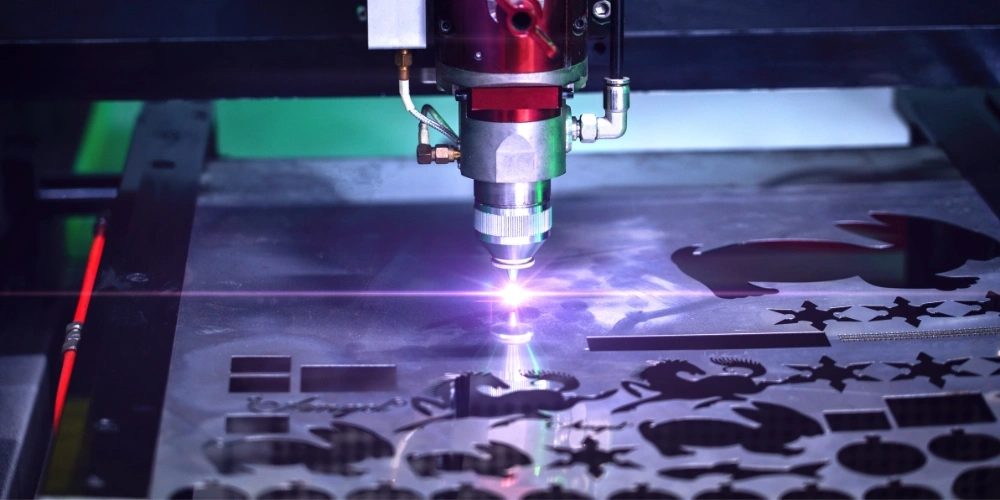

CNC Machining CNC Machining CNC Milling CNC Turning Sheet Metal Sheet Metal Fabrication Waterjet Cutting Laser Cutting Plasma Cutting Injection Molding Injection Molding Insert Molding

CNC Machining CNC Machining CNC Milling CNC Turning Sheet Metal Sheet Metal Fabrication Waterjet Cutting Laser Cutting Plasma Cutting Injection Molding Injection Molding Insert Molding

Metals are integral to the manufacturing industry where yield strength of metals is crucial for designing structures and components that can withstand expected loads.

Are you looking to make custom parts or prototypes for your car? Juize has you covered. Whether you are looking for parts for choppers, classic cars,

Yield strength is measured through a tensile test, a controlled experiment where a sample of the material is stretched until it begins to deform plastically.

Design considerations for laser engraving aluminum are similar to those for other laser engraving and marking types. We go into more detail on part marking

One of the most critical physical properties of metals is their yield strength. It determines how a material behaves under stress. But for any technical

Both bare and anodized aluminum can be engraved with fiber laser, though it can be more challenging to engrave bare aluminum with a CO2 laser

Why mark parts? As mentioned earlier, part marking enables accurate tracking of the serial number of a component through a marked QR code, data matrix

A powerful beam acts as the chisel in aluminum laser engraving, vaporizing particles off the metal surface to incise deep marks. The laser engraver should

Custom laser cutting parts involves several thoughtful considerations which must be in place before the process of customization begin so as to achieve accuracy and

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.