Electro Chemical Machining

This is another style of machining that uses electricity to make cuts—more specifically, holes. You’d want to opt for this when you’re set on creating

This is another style of machining that uses electricity to make cuts—more specifically, holes. You’d want to opt for this when you’re set on creating

In this kind of machining, you’re working with a tool called a broach, that’s essentially a cylindrical tool with teeth that are in increasingly larger

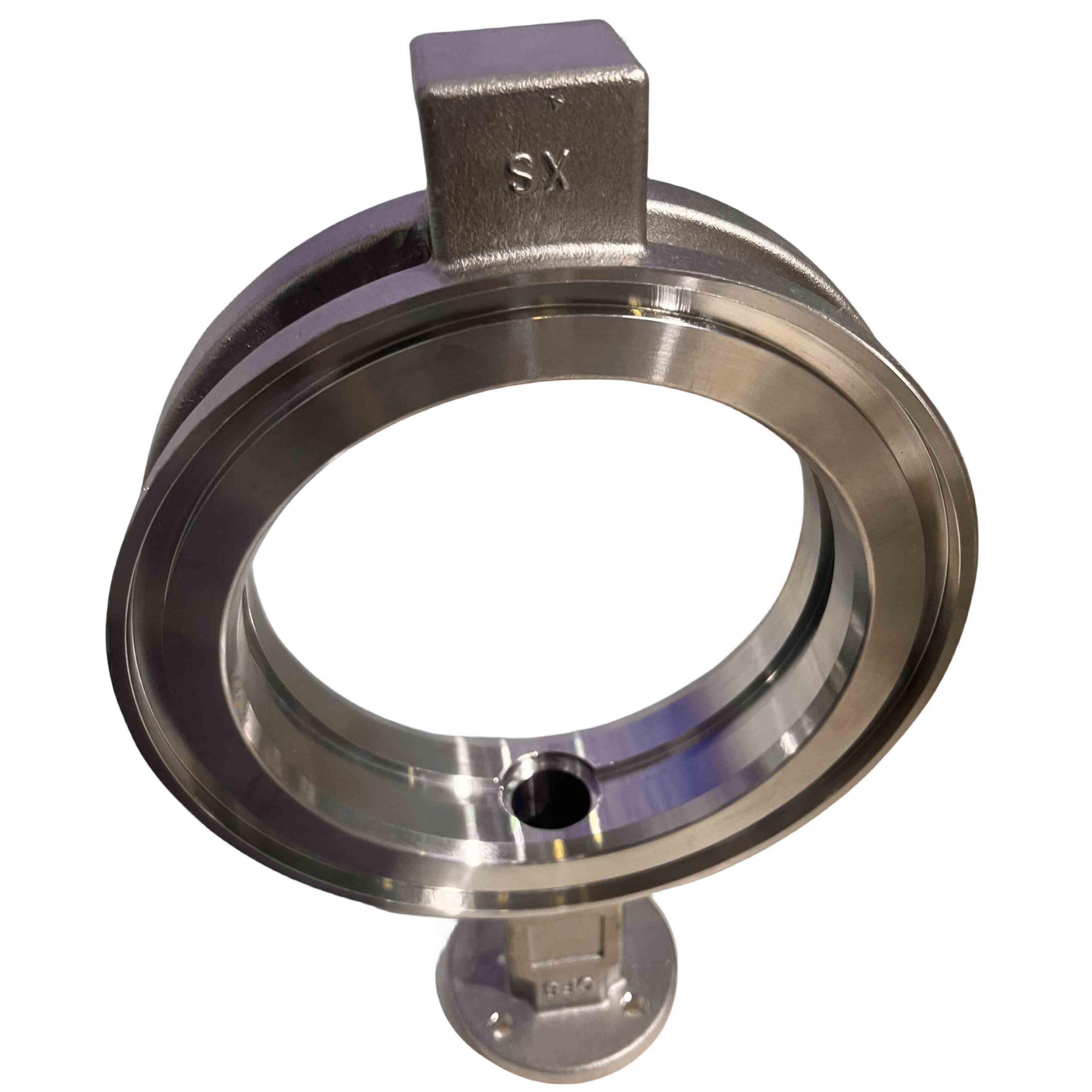

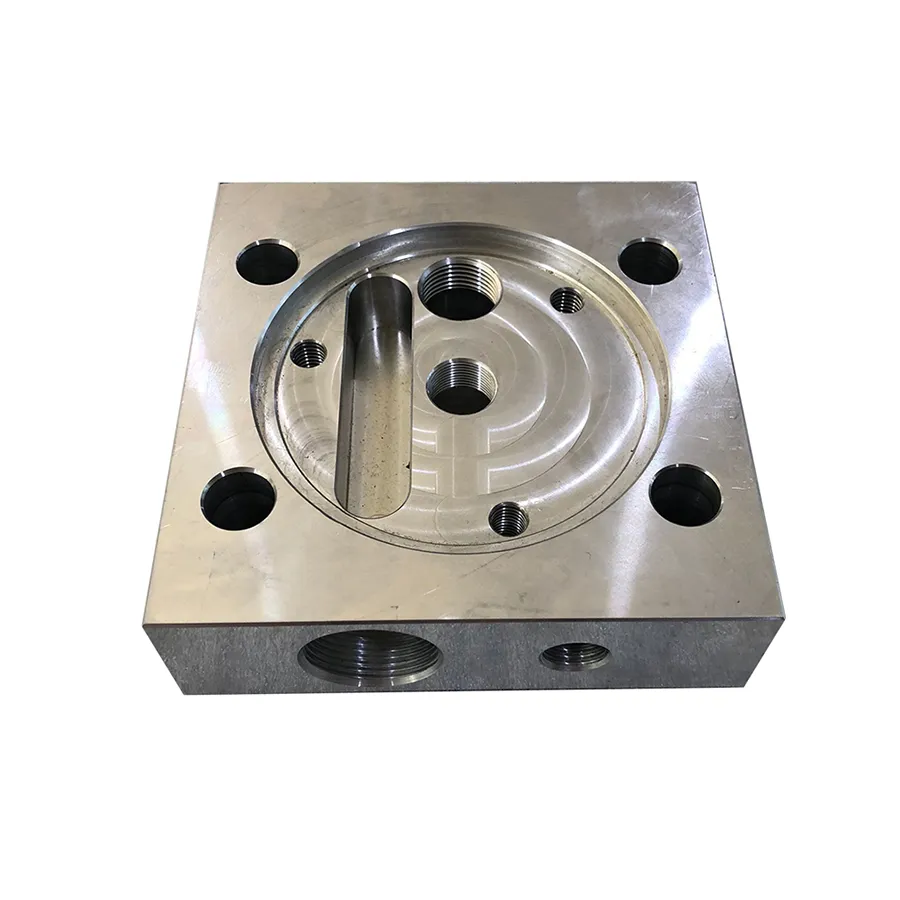

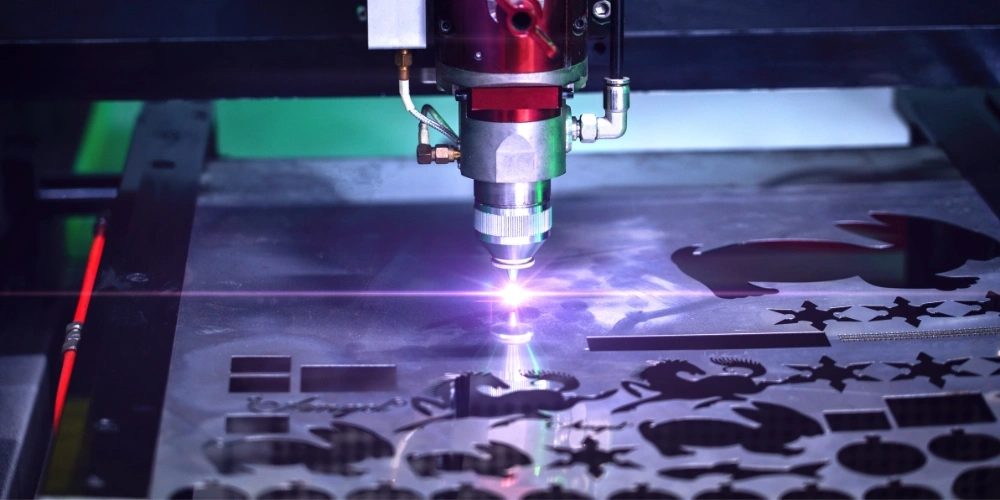

CNC machining is a manufacturing process that is typically categorized as a subtractive process or a process that’s primary goal is to remove material from

Applications of CNC metal parts are huge and wide ranging from the aerospace, automotive to medical devices, electronics industry even across oil & gas manufactures

If you’re looking for a way to create shorter lengths and cuts, sawing is it. There are tons of saws available, whether you need band

The precision of Plastic CNC Milling often surpasses that of injection molding. CNC Milling typically offers exceptional precision, often with tolerances in the range of

If you have large, flat surfaces you’re working with that’ll be processed further, planing is a great place to start. This method uses linear toolpaths

CNC Milling, while highly versatile, does have limitations when it comes to the shapes of plastic products it can produce. Some of the limitations include:

Also called EDM, for short, electric discharge machining releases electric discharges that create tiny craters into the surface of your workpiece. The quick succession of these fiery

A variety of applications can be performed using plastic CNC milling parts, such as prototyping and electronic enclosures in addition to aerospace stuffs also medical

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.