Meaning of OEM

OEM, an acronym for Original Equipment Manufacturer, refers to companies that design and produce components or products that are then sold and used by another

OEM, an acronym for Original Equipment Manufacturer, refers to companies that design and produce components or products that are then sold and used by another

When one needs some parts to be custom CNC machined and produced by manufacturers, several factors need consideration. Define Specifications: State the cut material, tolerances

Prepare Samples: The samples must be prepared with dimensions according to the relevant standard. There are multiple standards used. However, in general, the sample size is

Most Charpy impact testing machines are graduated to directly indicate the energies involved. As such, equations are generally not needed. However, the formula used to

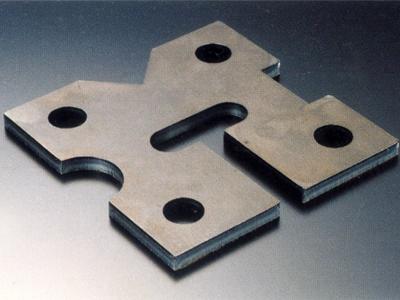

CNC machining is a manufacturing process that is typically categorized as a subtractive process or a process that’s primary goal is to remove material from

Speaking of advantages, let us give you a brief list of the common advantages and pros of CNC machining. Continuity Usually, CNC machines are designed

CNC machining involves the use of various materials to manufacture high precision components. Usual metals include aluminium, stainless steel and alloys as well as plastics

Several types of CNC machining technologies exist. Here are some common ones: Milling: Includes cutting material out of a workpiece with rotating knives. Turning: Turns

The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy

Besides the fact that CNC is high-tech and advanced, there are a ton of important benefits and factors that make it extraordinary. One of the

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.