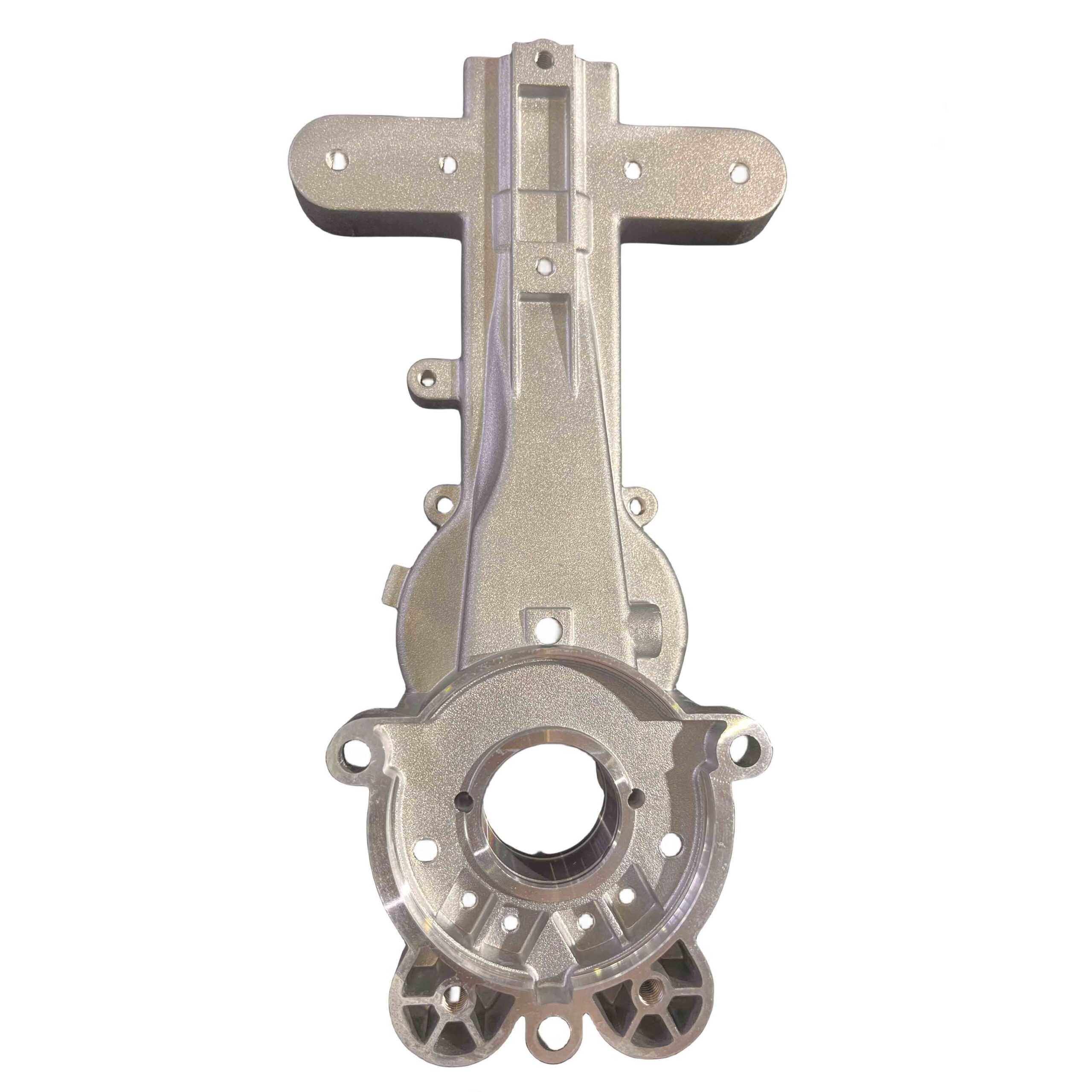

Precision Manufacturing for Large and Heavy-Duty Components

In industries where performance is measured in both precision and power, the ability to manufacture large-scale, heavy-duty components is a true test of a supplier’s

In industries where performance is measured in both precision and power, the ability to manufacture large-scale, heavy-duty components is a true test of a supplier’s

OEM CNC Machining Service offers a multitude of advantages that make it a preferred choice for many industries seeking precision and efficiency in manufacturing processes.

Applications of CNC metal parts are huge and wide ranging from the aerospace, automotive to medical devices, electronics industry even across oil & gas manufactures

Moving a product from initial concept to a reliable, cost-effective component requires more than advanced machinery—it demands early and informed collaboration. At Juize Machinery, we

There are many factors that affect the cost of CNC machining. Next, we will analyze the cost of CNC machining from several main aspects.

In an era where product innovation often hinges on component complexity, the ability to produce intricate, high-precision parts is what separates industry leaders from the

CNC technology can process complex design parts on various materials with extreme precision, which is the foundation of modern industry and cutting-edge scientific and technological

In the world of precision manufacturing, the journey of a part does not end when it leaves the machine. Its surface—the final frontier—plays a decisive

As electronic devices become more powerful and compact, managing heat has transformed from a technical consideration into a fundamental requirement for reliability and performance. At

In the simplest of terms, CNC prototyping is a type of machining process that is used before producing or manufacturing a single piece or a

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.