The Common CNC Machining Operations

Many industries such as construction, aerospace, agriculture, automotive, or even use CNC machining to manufacture various parts. Even CNC machining is essential for producing multiple

Many industries such as construction, aerospace, agriculture, automotive, or even use CNC machining to manufacture various parts. Even CNC machining is essential for producing multiple

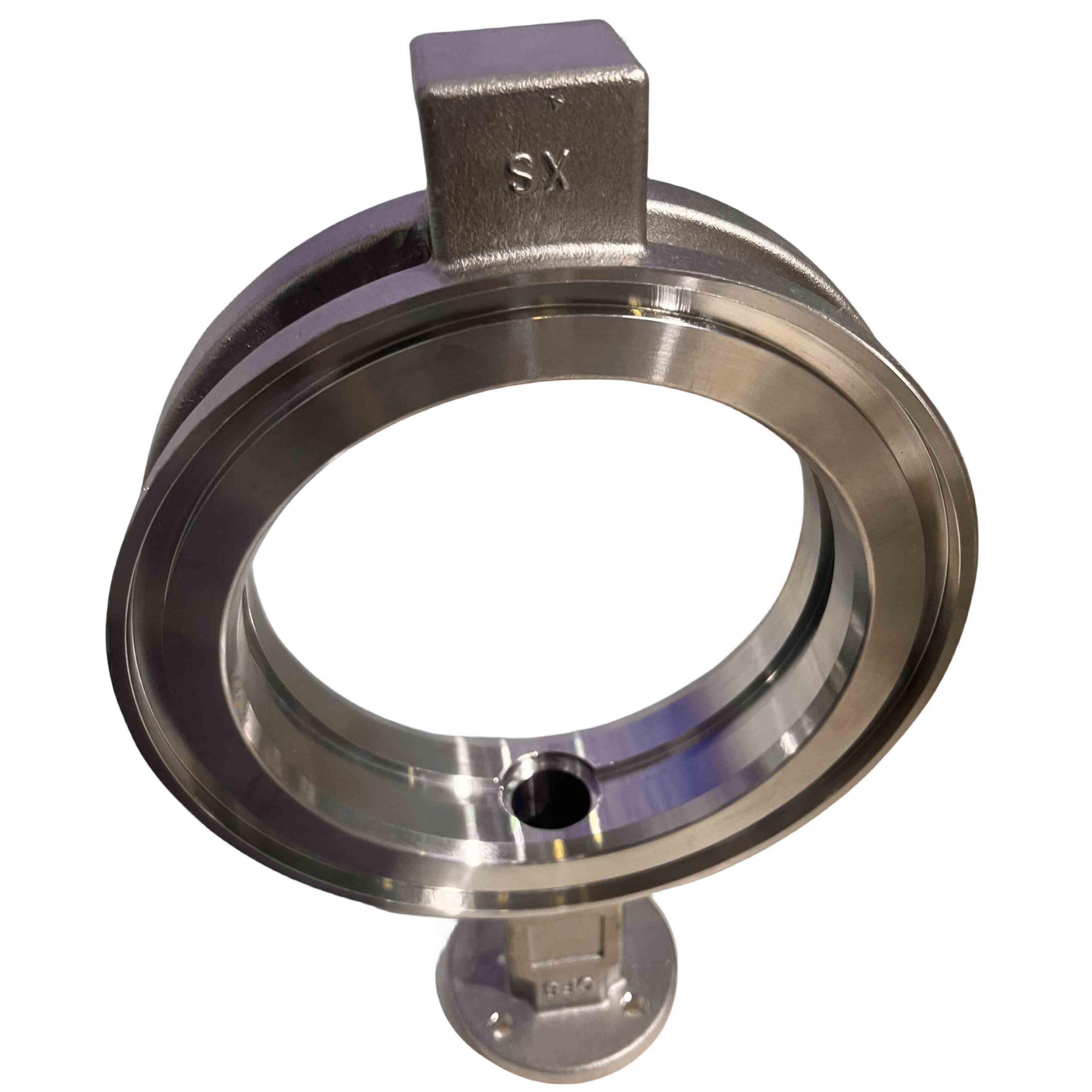

Gravity casting, is a metal casting process where molten metal is poured into a reusable mold under the force of gravity. While it offers advantages

5-Axis CNC machining is more sophisticated than traditional CNC Machining. Regular 3-axis machines move in three directions (X, Y, and Z coordinates), but the 5-axis

Gravity casting, also known as permanent mold casting, is a metal casting process where molten metal is poured into a reusable mold under the force

Milling is an essential CNC machine operation. The operating process of a milling machine determines the operational capability of that machine. According to those capabilities,

Gravity casting (also known as permanent mold casting) is a metal casting process where molten metal is poured into a reusable metal mold under the

CNC machining can operate many complex functions with minimal human effort. It offers multiple advantages over machining that does not have the power of the

Aluminum Alloys: Widely used due to their lightweight, corrosion resistance, and good mechanical properties. Zinc Alloys: Known for their excellent fluidity, making them ideal for

CNC stands for Computer Numerical Control, and CNC machining is a computerized manufacturing process. You can make your industrial manufacturing process fully automated and more

While gravity casting offers numerous advantages, achieving high-quality castings requires careful attention to several critical factors: Mold Design and Preparation: Mold Material Selection: Choose mold materials

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.