Importance of Molds in Die Casting

Molds, or dies, are critical to the die casting process. Designed to withstand extreme conditions, these molds are crafted from high-grade steel. They consist of

Molds, or dies, are critical to the die casting process. Designed to withstand extreme conditions, these molds are crafted from high-grade steel. They consist of

To ensure precision in gravity casting (also known as permanent mold casting), several key factors must be controlled throughout the process. Here’s a detailed breakdown:

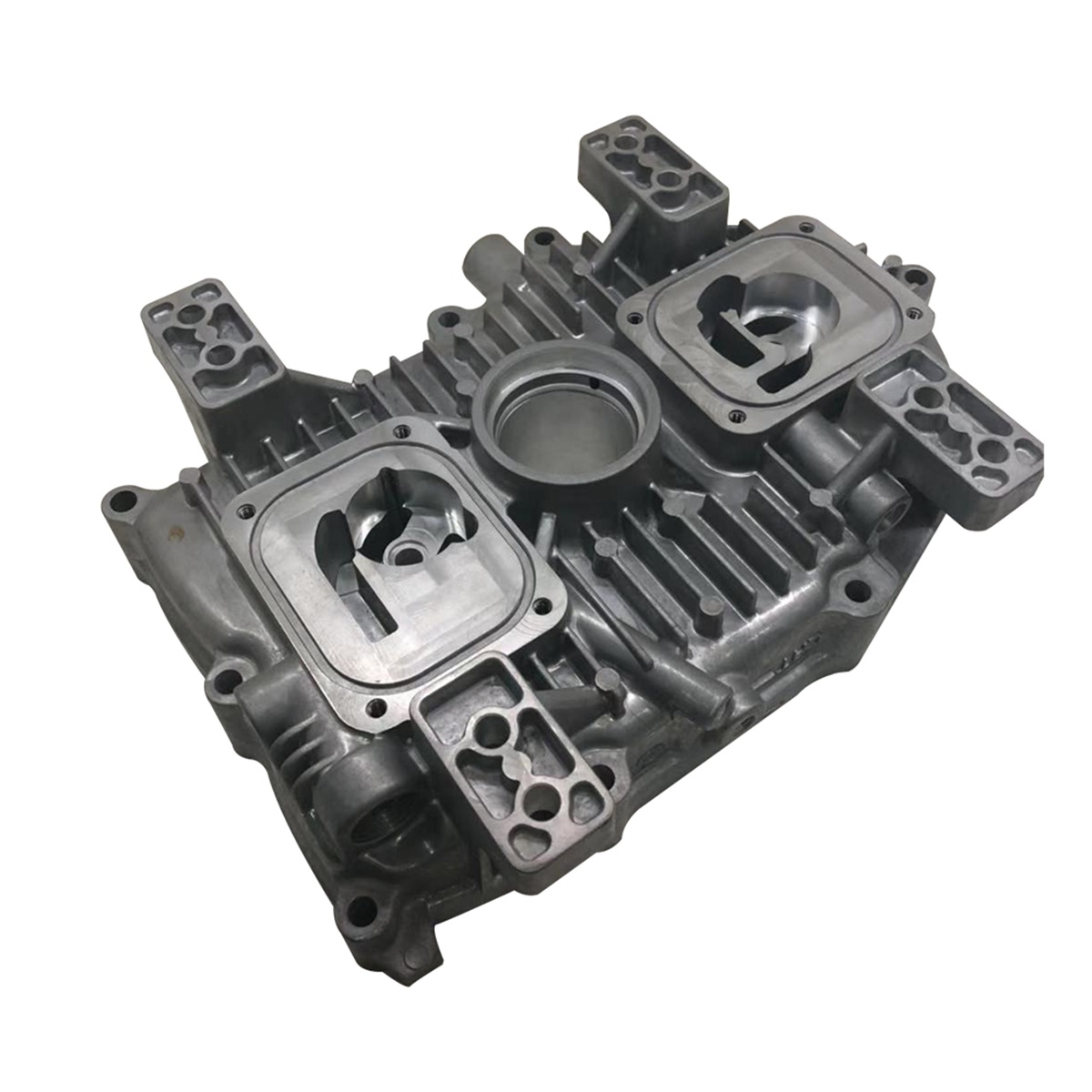

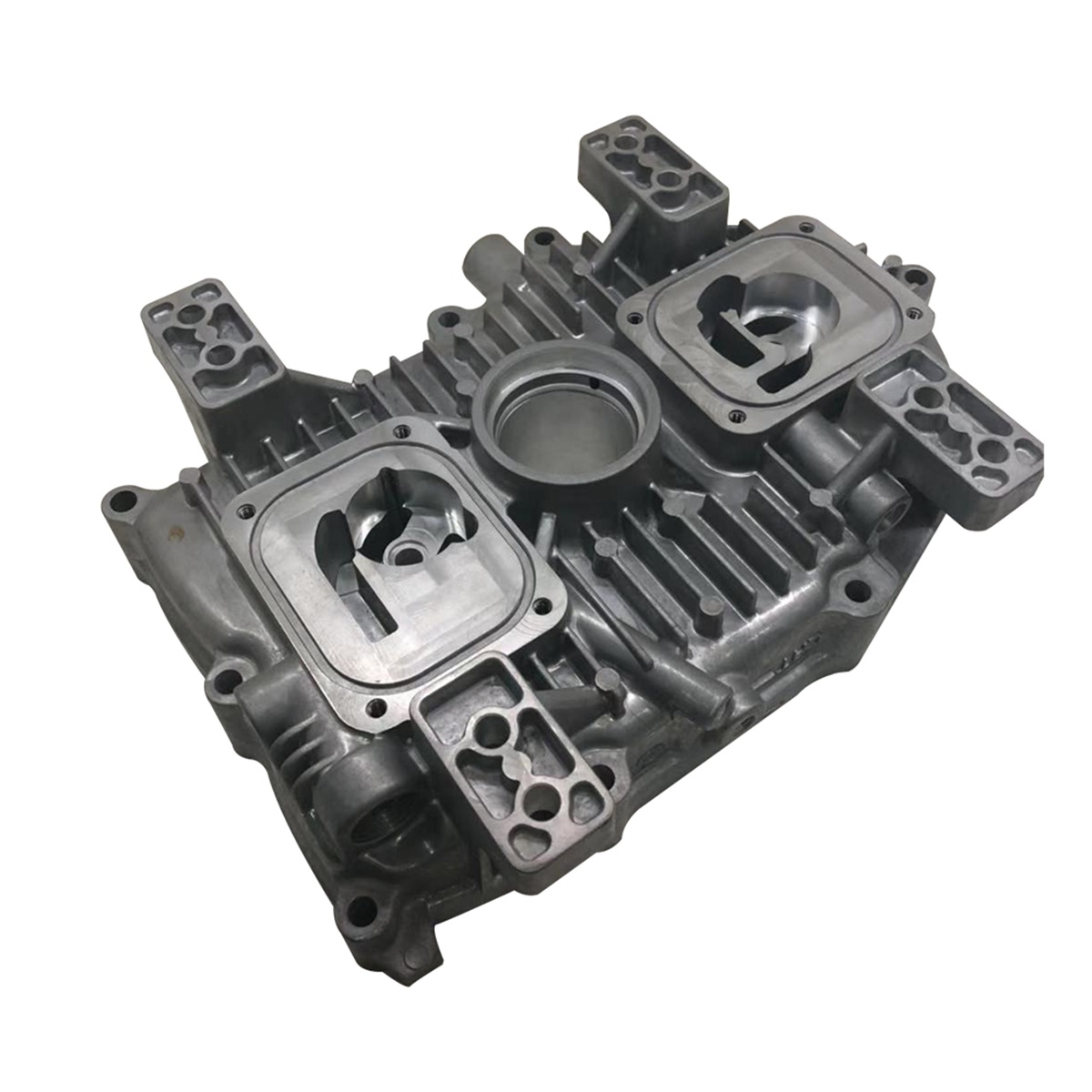

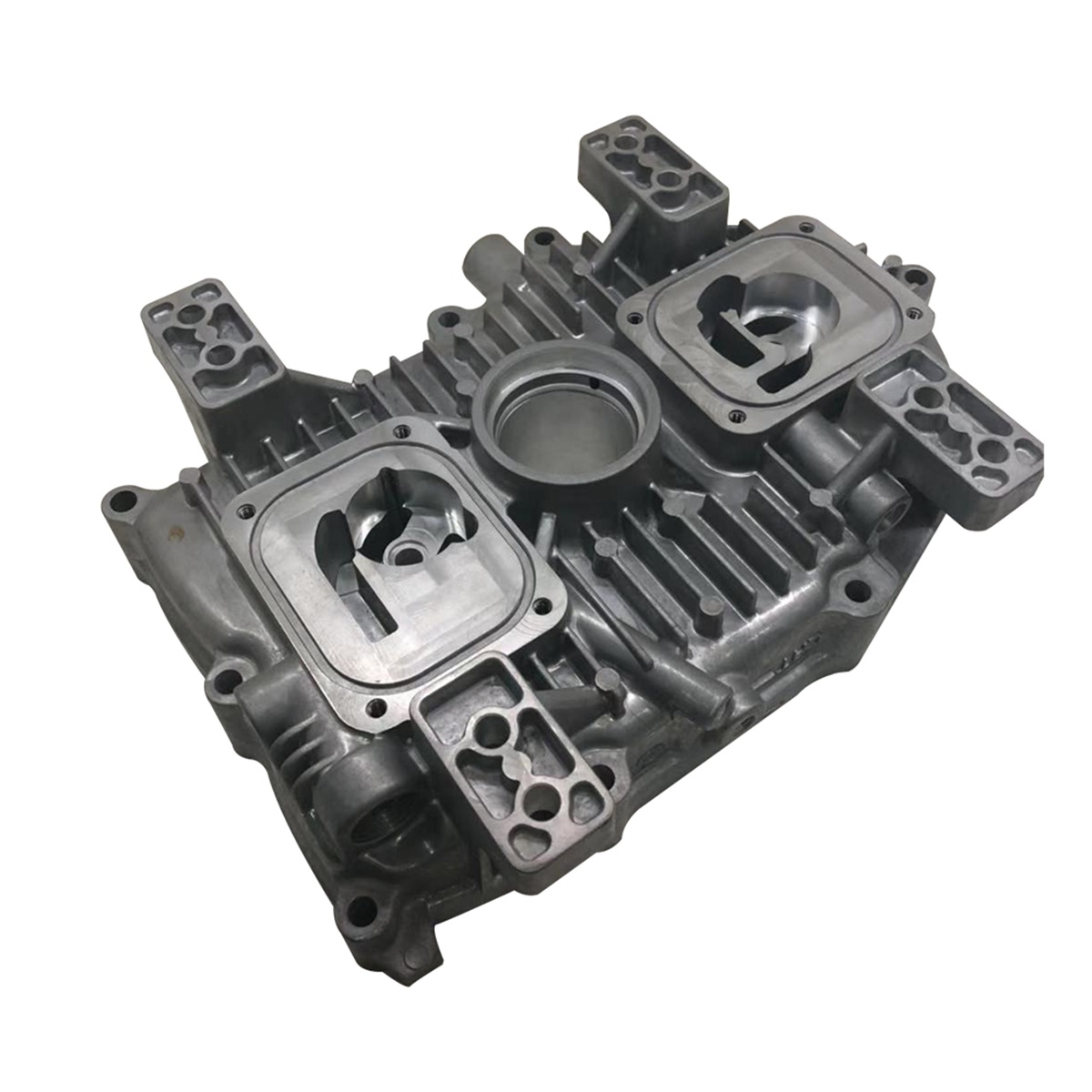

Gravity casting, also known as permanent mold casting or gravity die casting, relies on reusable molds (typically made of metal) to produce high-quality cast parts.

Die casting is a dynamic casting process where molten metal is injected under high pressure into a precision-engineered mold, known commonly as a die. This

Gravity casting, also known as permanent mold casting, is a widely used metal casting process where molten metal is poured into a reusable mold under

1. Global Supply and Demand Dynamics Industrial Demand: Steel consumption is heavily tied to construction, automotive, and manufacturing sectors. Economic booms increase demand, while recessions depress

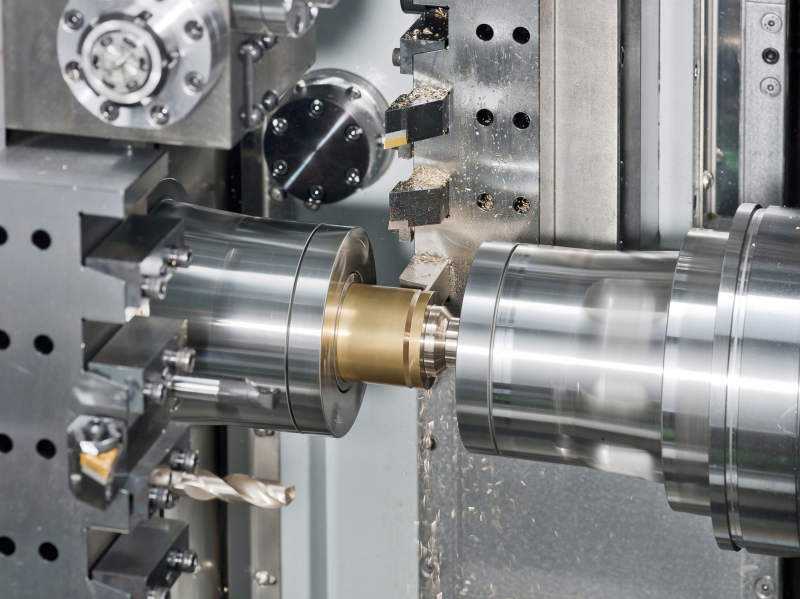

CAD design means Computer-Aided Design. The CAD design of a 3D or 2D solid part is the first step of a CNC machining process. You

CNC machining companies use quality control procedures to measure the quality of a CNC machine’s product. Every production unit must follow specific quality control procedures

Introduction to the Trade-Off Gravity casting, as a metal forming process, inherently requires manufacturers to balance between production costs and dimensional precision. This balance becomes

Gravity casting, also known as permanent mold casting, is a metal casting process that utilizes gravity to fill molds with molten metal. It is widely

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.