Common Machine Tool Types

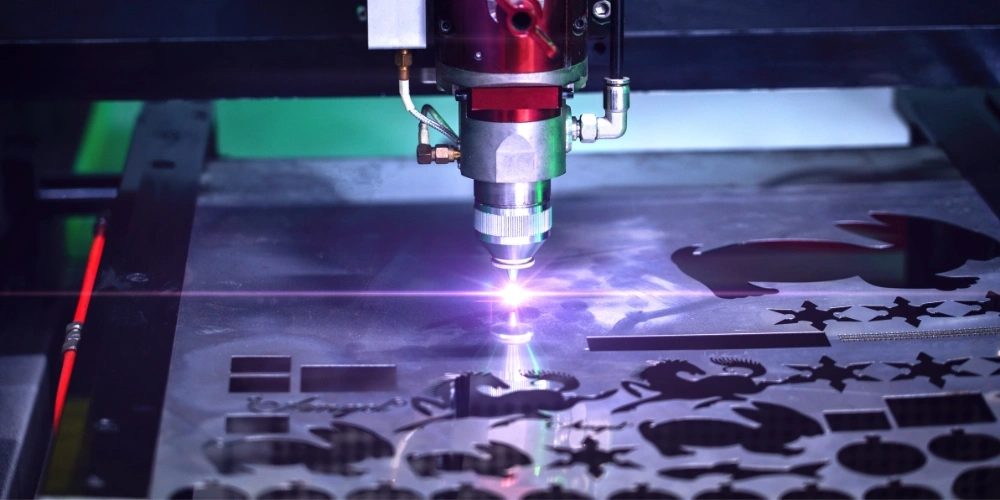

Here’s an overview of common machine tool types used in machining processes, categorized by their primary functions and technologies: 1. Conventional Machining Machines Lathe Used for turning

Here’s an overview of common machine tool types used in machining processes, categorized by their primary functions and technologies: 1. Conventional Machining Machines Lathe Used for turning

Quality control in steel investment casting is integral to ensuring precise and reliable components. The process begins with a thorough inspection of wax patterns, correcting

Turn-mill compound machining, also known as multi-tasking machining, integrates turning and milling operations into a single machine tool to perform complex part processing in one setup.

In investment casting, various steel types cater to diverse component needs. Choices, driven by specific product requirements, include: Carbon Steel: General-purpose use. Offers cost-effective strength.

Here are the key steps involved in the investment casting process: Wax Pattern Creation: Injection Molding: Create wax patterns by injecting molten wax into

Achieving the optimal balance between dimensional tolerances and cost efficiency is a critical challenge in engineering and manufacturing. Here’s a structured approach to address this

Here’s an overview of common surface treatment options for metal parts, along with their applications and characteristics: 1. Electroplating Process: Depositing a thin layer of metal (e.g.,

In the realm of investment casting, steel, known for its robustness, excels in strength, durability, and versatility. Offering excellent corrosion and heat resistance, its machinability

Investment casting offers a plethora of advantages that set it apart in the world of production processes. Let’s delve into the key merits that make

When creating technical drawings for custom metal machined parts, the following essential elements must be included to ensure manufacturability, clarity, and compliance with industry

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.