Surface Roughness of Metal Components

Surface roughness refers to the microscopic irregularities and texture on the surface of a metal component. It is a critical parameter in manufacturing and engineering,

Surface roughness refers to the microscopic irregularities and texture on the surface of a metal component. It is a critical parameter in manufacturing and engineering,

CNC technology can process complex design parts on various materials with extreme precision, which is the foundation of modern industry and cutting-edge scientific and technological

Tolerance standards for mechanical components are critical to ensuring interchangeability, functionality, and reliability in manufacturing and assembly. These standards define allowable deviations in dimensions, geometries,

Here are common methods for removing rust from metal parts Mechanical Removal Methods Wire Brushing: Use a steel wire brush (manual or power tool attachment)

CNC machinery and equipment are perfect for batch production – and it’s simply because of one (1) word – repeatability. Repeatability or the idea of

Stainless steel is highly resistant to rust, but it is not 100% rust-proof. Its corrosion resistance depends on its composition, environment, and maintenance. Here’s why: 1. How

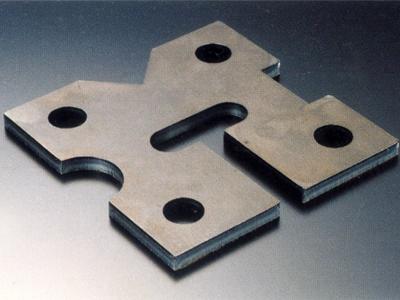

Metal bending, while versatile, presents several challenges that require careful consideration. Material springback is a primary concern, where the metal tends to revert slightly toward

Stainless steel is a versatile and corrosion-resistant alloy composed primarily of iron, chromium (minimum 10.5%), and often other elements like nickel, molybdenum, or carbon. Its

Metal bending offers several distinct advantages that make it a preferred method in various fabrication scenarios. Firstly, it is cost-effective compared to other forming methods.

Metal bending finds extensive applications across various industries, each leveraging the process to craft essential components and intricate designs. In the automotive industry, metal bending

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.