Metal 3D Printing

Here’s a comprehensive overview of metal 3D printing, covering key technologies, processes, materials, and applications: Core Terminology Metal Additive Manufacturing (AM) Direct Metal Printing Metal 3D

Here’s a comprehensive overview of metal 3D printing, covering key technologies, processes, materials, and applications: Core Terminology Metal Additive Manufacturing (AM) Direct Metal Printing Metal 3D

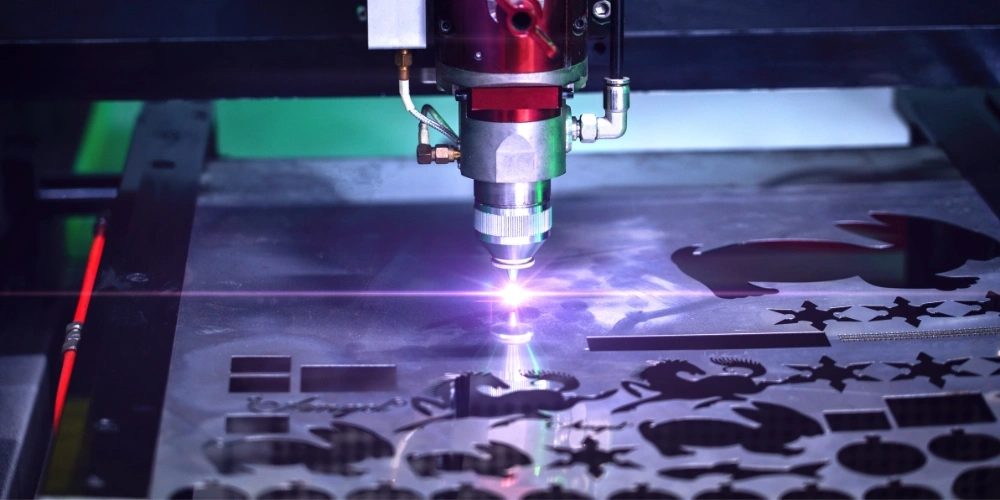

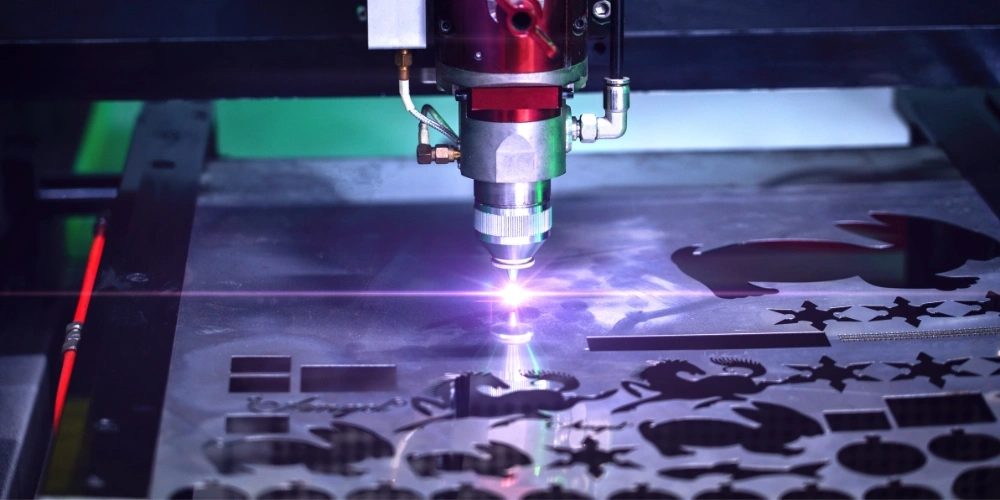

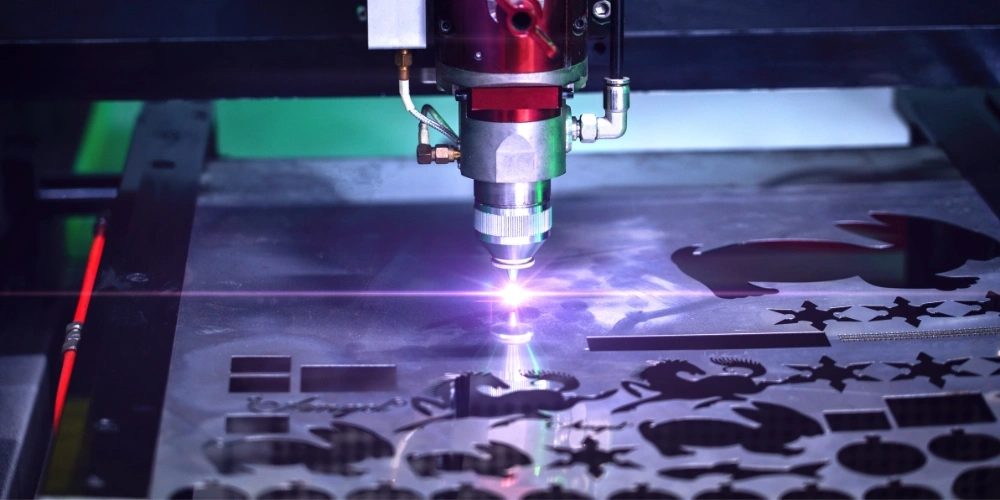

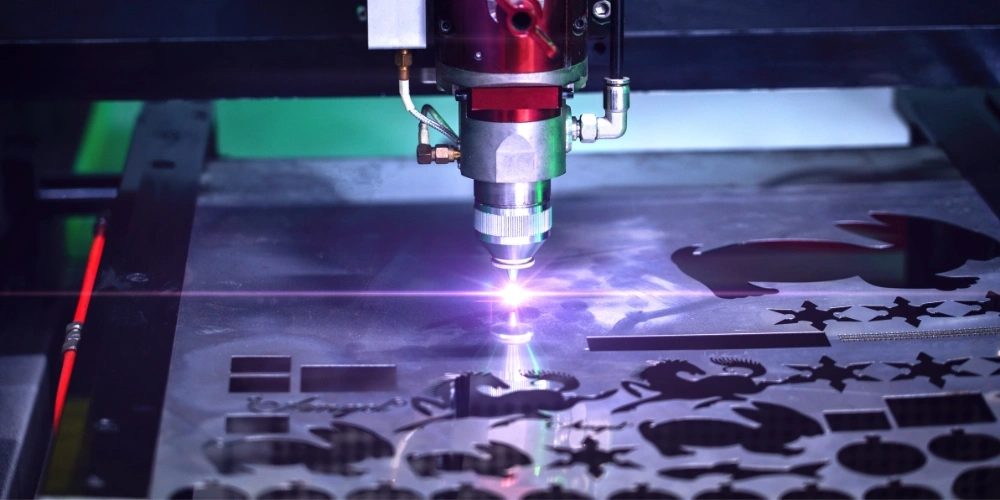

In a nutshell, CNC plasma cutting is a subtractive process using plasma as the cutting material. The term “CNC,” refers to the machine being used.

Here’s an overview of emerging processing technologies for metal components, highlighting key innovations and their industrial significance: 1. Additive Manufacturing (AM) of Metal Parts Powder Bed

When we say “rapid prototyping”, it is a procedure that will let you produce a part rapidly and examine the capability and the possibility of

Purpose & Function: These tools are used to examine, measure, test, and verify the quality, specifications, dimensions, functionality, and integrity of parts or accessories. Their goal is

Quality control in steel investment casting is integral to ensuring precise and reliable components. The process begins with a thorough inspection of wax patterns, correcting

Here’s a comprehensive analysis of the current global steel price dynamics, based on the latest market data and trends: 1. Global Market Disruptions from U.S. Tariffs

Metal pressing, or stamping, encompasses a variety of techniques to shape metal sheets into desired forms, catering to diverse industrial needs. Blanking and punching are

Here are the key steps involved in the steel investment casting process: Wax Pattern Creation: Injection Molding: Create wax patterns by injecting molten wax

Based on the latest developments up to early June 2025, the outlook for U.S.-China tariffs involves both significant de-escalation and lingering structural challenges. Here’s a

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.