Importance of Molds in Die Casting

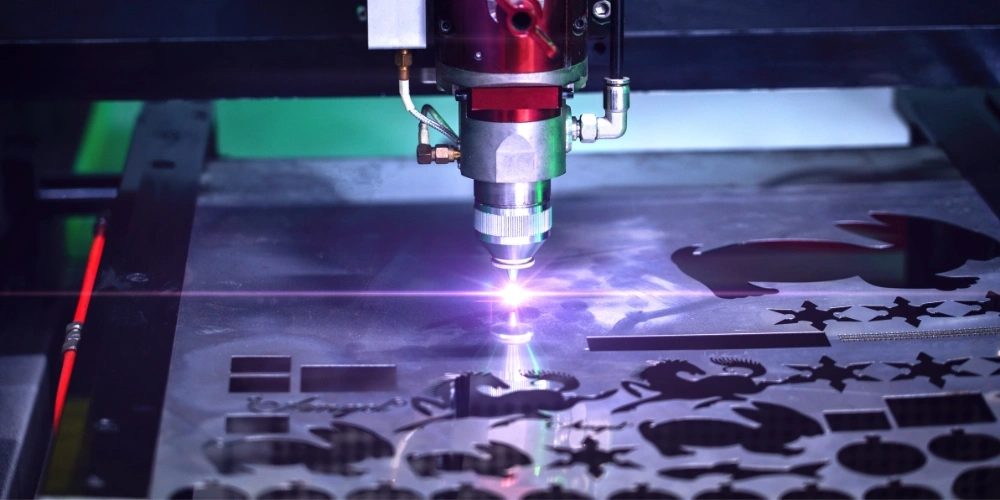

Molds, or dies, are critical to the die casting process. Designed to withstand extreme conditions, these molds are crafted from high-grade steel. They consist of

Molds, or dies, are critical to the die casting process. Designed to withstand extreme conditions, these molds are crafted from high-grade steel. They consist of

In an era where industrial progress and environmental responsibility must go hand in hand, forward-thinking companies are redefining what it means to be a world-class

Die casting is a dynamic casting process where molten metal is injected under high pressure into a precision-engineered mold, known commonly as a die. This

In the age of Industry 4.0, the most advanced manufacturing is defined not only by machinery but by data intelligence. The true mark of a modern

In specialized industries where precision, durability, and performance are non-negotiable, components are not just parts—they are critical system enablers. A failure in a gear, valve,

Die casting is a precision metal casting process that involves forcing molten metal under high pressure into a mold cavity. This method is distinguished by

Forging is mainly divided into open-die forging and closed-die forging. Open die forging does not require the use of molds, has low precision, requires subsequent

In today’s complex product ecosystems, the value delivered by a manufacturing partner is increasingly measured not just by the quality of individual components, but by

Titanium alloy has a low density of 4.5g/cm³, about 60% of steel. Its strength is higher than aluminum alloy and steel, tensile strength can reach

In a landscape defined by rapid technological evolution and shifting market demands, the ability to innovate and adapt has become the ultimate competitive advantage. More

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.