Warm Forging

This process is done at intermediate temperatures between hot and cold forging. Warm forging offers a smoother finish than hot forging, but it requires more

This process is done at intermediate temperatures between hot and cold forging. Warm forging offers a smoother finish than hot forging, but it requires more

Here’s an overview of common rubber materials, categorized by type and described: Natural Rubber (NR): Source: Derived from the latex of the Hevea brasiliensis tree. Key Properties: Excellent elasticity,

Hot forging involves shaping the metal above its recrystallization point, which is typically between 0.3 and 0.5 times its absolute melting temperature (Tm). With this,

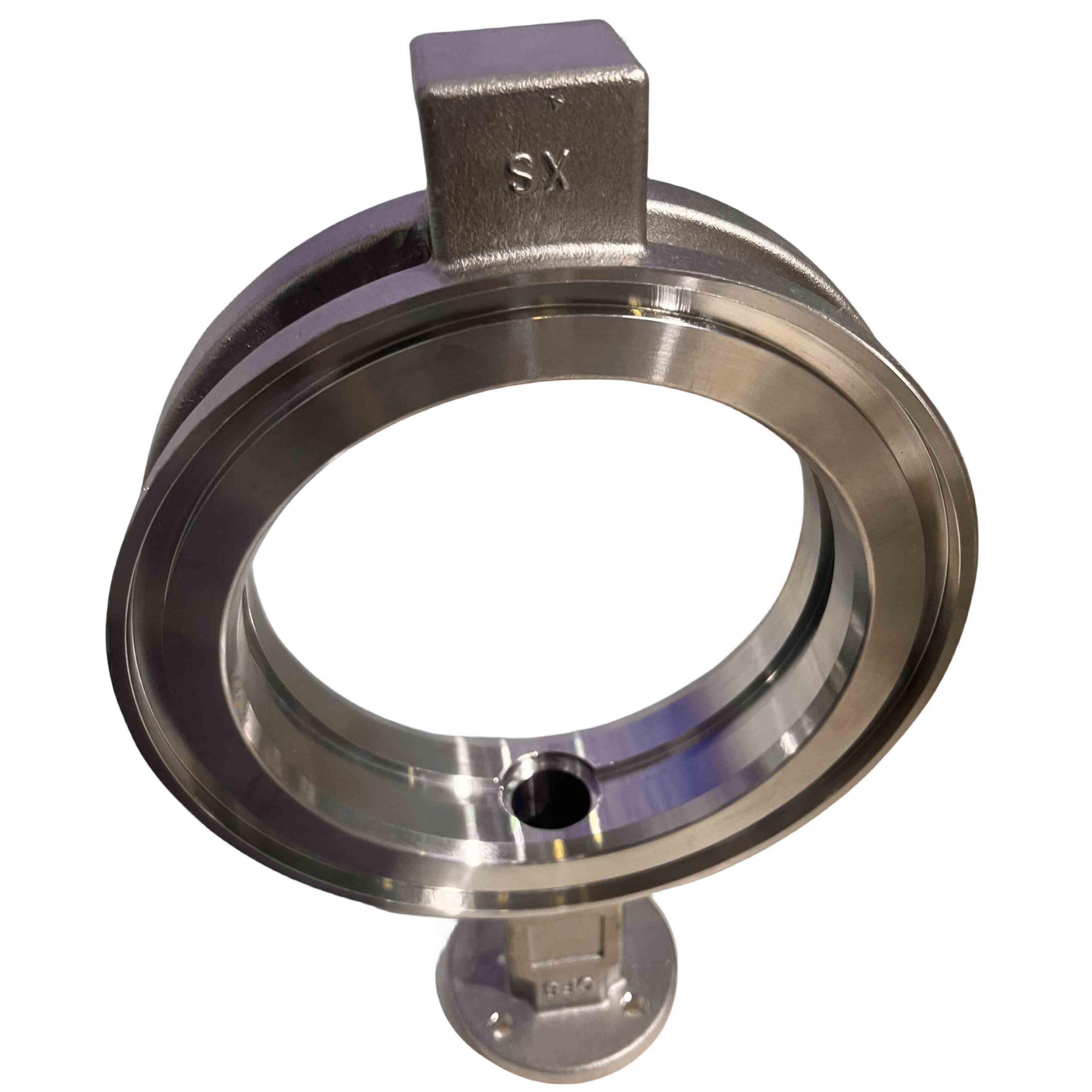

This process starts with a round billet, and then a hole is punched in the center, turning it into a thick ring. The ring is

Metal hardness (typically measured on scales like Rockwell C – HRC, or Vickers – HV) is a critical property determining a part’s suitability for specific

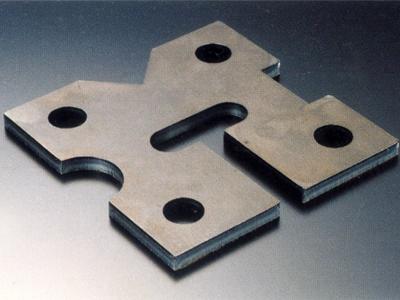

This is a process where a heated billet is placed between shaped dies that contain the exact outline of the part. The metal fills the

Open-die forging, also known as free-forging, shapes hot metal between flat dies or a hammer and an anvil. There are no side-walls or full molds

Here are the primary methods for detecting and verifying the magnetic field in Magnetic Particle Testing (MT) equipment, as per industry standards (e.g., ASTM E1444/E1444M,

Here’s a comprehensive guide to selecting metal fabrication methods, focusing on key decision factors: Key Factors Influencing Method Selection: Part Geometry & Complexity: Simple, Constant

Casting is usually used for intricate parts: Automotive: Parts such as engine blocks, cylinder heads, and brackets are often cast because they have complex

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.