Benefits of Heat Treatment

There are many advantages you get when heat treating metals, such as: The process improves the mechanical properties of metals, making them last much

There are many advantages you get when heat treating metals, such as: The process improves the mechanical properties of metals, making them last much

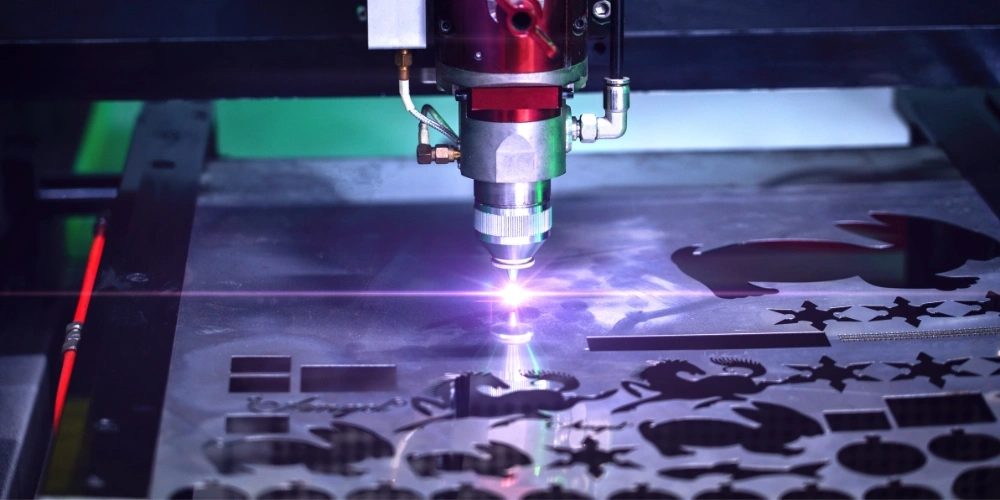

Welding is a fundamental fabrication process that joins materials, typically metals or thermoplastics, by causing coalescence. This is most often done by melting the workpieces

Yes, absolutely. Rust preventative oils have a significantly negative and often dangerous impact on the welding process and the quality of the finished weld. Using oil-coated

Most factories use special equipment and tools to control the heat treatment processes. Furnaces There are different kinds of furnaces used in the heat

The cooling process immediately following the forging operation is a critical but often overlooked stage in metalworking. It is not merely about bringing the part

Steel This is the most commonly used metal when it comes to heat treatment. The carbon content in it can be adjusted to change how

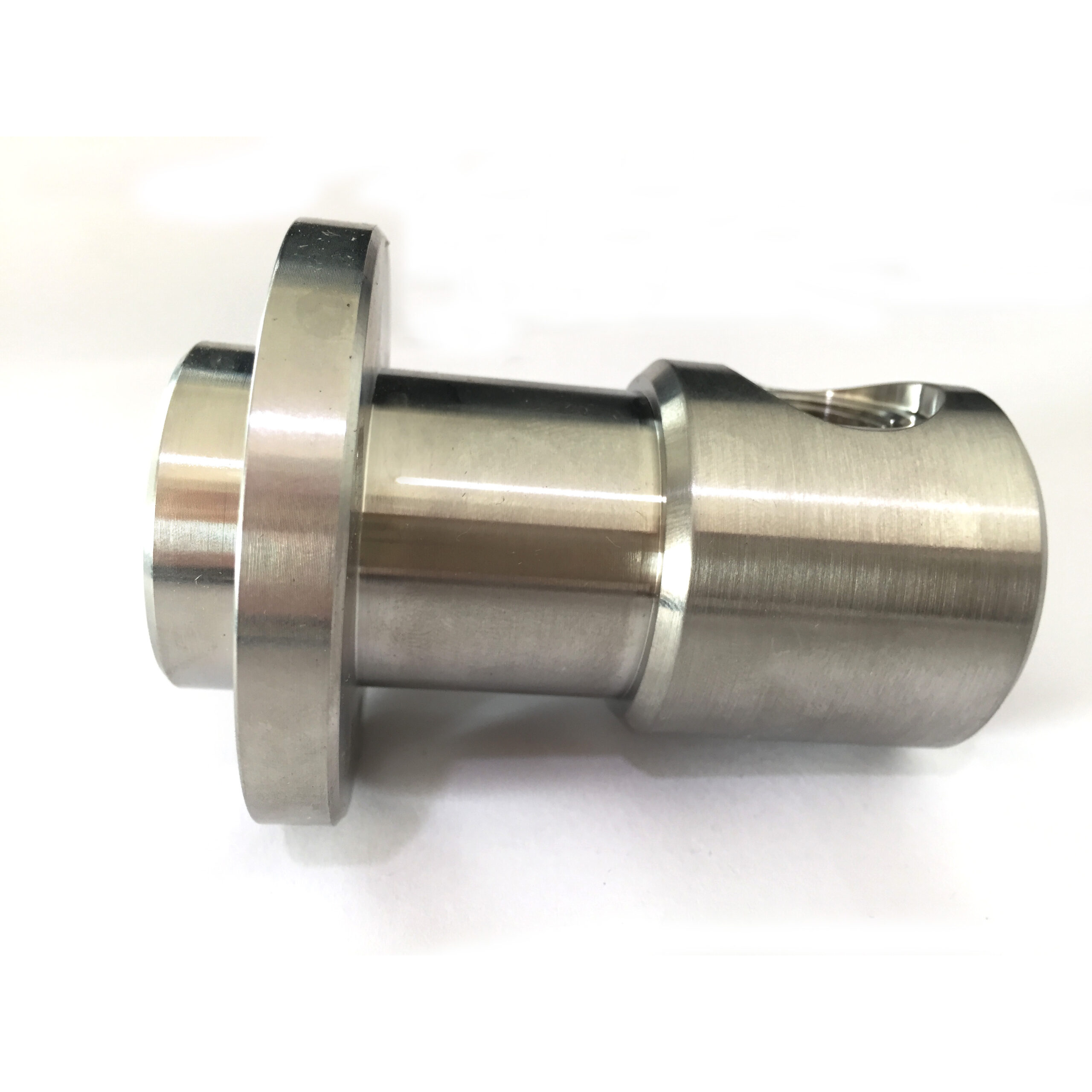

Selecting the right dimensional inspection tool, or gage, is a critical decision in manufacturing and quality control. The wrong choice can lead to inaccurate measurements,

This process hardens only the surface of the workpiece, but the inside remains soft. Carburizing adds carbon to the surface of the metal, while Nitriding

Key Points for Metal Parts Repair: A Comprehensive Guide Metal part repair is a critical skill in manufacturing, automotive, aerospace, and maintenance industries. A successful

The hardness of a metal fastener (such as screws, bolts, nuts, and rivets) is a critical mechanical property that defines its resistance to permanent deformation,

WhatsApp us

Ready to Work Together? Build a project with!

*You can upload your design here so that we can provide you with a more accurate quote.